Water-borne epoxy resin-modified cement mortar used for structure reinforcement and production method thereof

A water-based epoxy resin and epoxy resin technology, applied in the field of chemical building materials, can solve the problems of impermeability, carbonation resistance, frost resistance and other durability properties and rare structures, and achieve excellent mechanical properties and technology Excellent performance, good stability and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

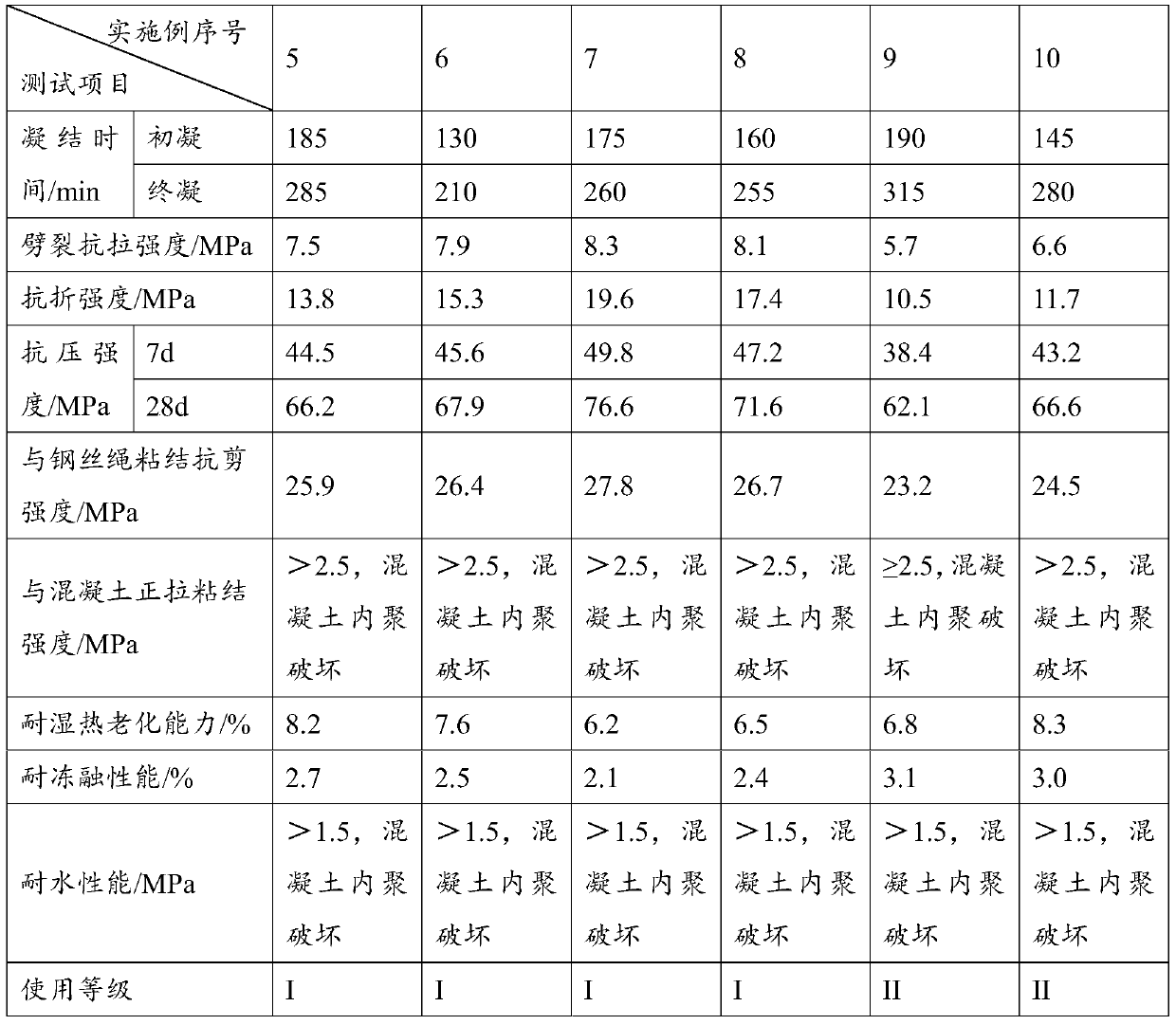

Examples

Embodiment 1

[0082] Embodiment 1 emulsified water-based epoxy resin curing agent ZB-804

[0083] The emulsifying epoxy resin curing agent ZB-804 of the present embodiment, raw materials include epoxy resin E-51, epoxy resin E-44, triethylenetetramine, propylene glycol methyl ether, polyethylene glycol 400 and an appropriate amount of Ionized water; the molar ratio of each component is:

[0084] Epoxy Resin E-51: Epoxy Resin E-44: Triethylenetetramine: Propylene Glycol Methyl Ether: Polyethylene Glycol 400=0.25︰0.30︰0.85︰0.15︰0.45;

[0085] Prepared by:

[0086] (1) Prepare each component according to the proportion, including epoxy resin E-51 100g, epoxy resin E-44 140g, triethylenetetramine 130g, propylene glycol methyl ether 15g, 188g polyethylene glycol 400;

[0087] (2) Epoxy resin E-51 and epoxy resin E-44 are mixed at room temperature, dissolved with propylene glycol methyl ether, and added in a reaction vessel with a condensation and stirring device;

[0088] (3) Slowly add polye...

Embodiment 2

[0094] Example 2 Emulsified water-based epoxy resin curing agent ZB-804

[0095] The emulsified water-based epoxy resin curing agent ZB-804 of the present embodiment, raw materials include epoxy resin E-51, epoxy resin E-44, triethylenetetramine, propylene glycol methyl ether, polyethylene glycol 400 and an appropriate amount of Ionized water; the molar ratio of each component is:

[0096] Epoxy resin E-51: epoxy resin E-44: triethylenetetramine: propylene glycol methyl ether: polyethylene glycol 400 = 0.40: 0.45: 1.15: 0.30: 0.90;

[0097] Prepared by:

[0098] (1) Prepare each component according to the proportion, including epoxy resin E-51 150g, epoxy resin E-44 200g, triethylenetetramine 168g, propylene glycol methyl ether 27g, 300g polyethylene glycol 400;

[0099] (2) Epoxy resin E-51 and epoxy resin E-44 are mixed at room temperature, dissolved with propylene glycol methyl ether, and added in a reaction vessel with a condensation and stirring device;

[0100] (3) Sl...

Embodiment 3

[0106] Example 3 Emulsified water-based epoxy resin curing agent ZB-804

[0107] The emulsified water-based epoxy resin curing agent ZB-804 of the present embodiment, raw materials include epoxy resin E-51, epoxy resin E-44, triethylenetetramine, propylene glycol methyl ether, polyethylene glycol 400 and an appropriate amount of Ionized water; the molar ratio of each component is:

[0108] Epoxy resin E-51: epoxy resin E-44: triethylenetetramine: propylene glycol methyl ether: polyethylene glycol 400 = 0.32: 0.35: 0.98: 0.20: 0.58;

[0109] Prepared by:

[0110] (1) Prepare each component according to the proportion, including 120g of epoxy resin E-51, 155g of epoxy resin E-44, 143g of triethylenetetramine, 18g of propylene glycol methyl ether, and 232g of polyethylene glycol 400;

[0111] (2) Epoxy resin E-51 and epoxy resin E-44 are mixed at room temperature, dissolved with propylene glycol methyl ether, and added in a reaction vessel with a condensation and stirring devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com