Process for producing a locally hardened profile component, locally hardened profile component and use of a locally hardened profile component

A formed part, partial technology, applied in the application field of formed parts, to achieve the effect of reduced metal plate thickness, improved functional characteristics, and high resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

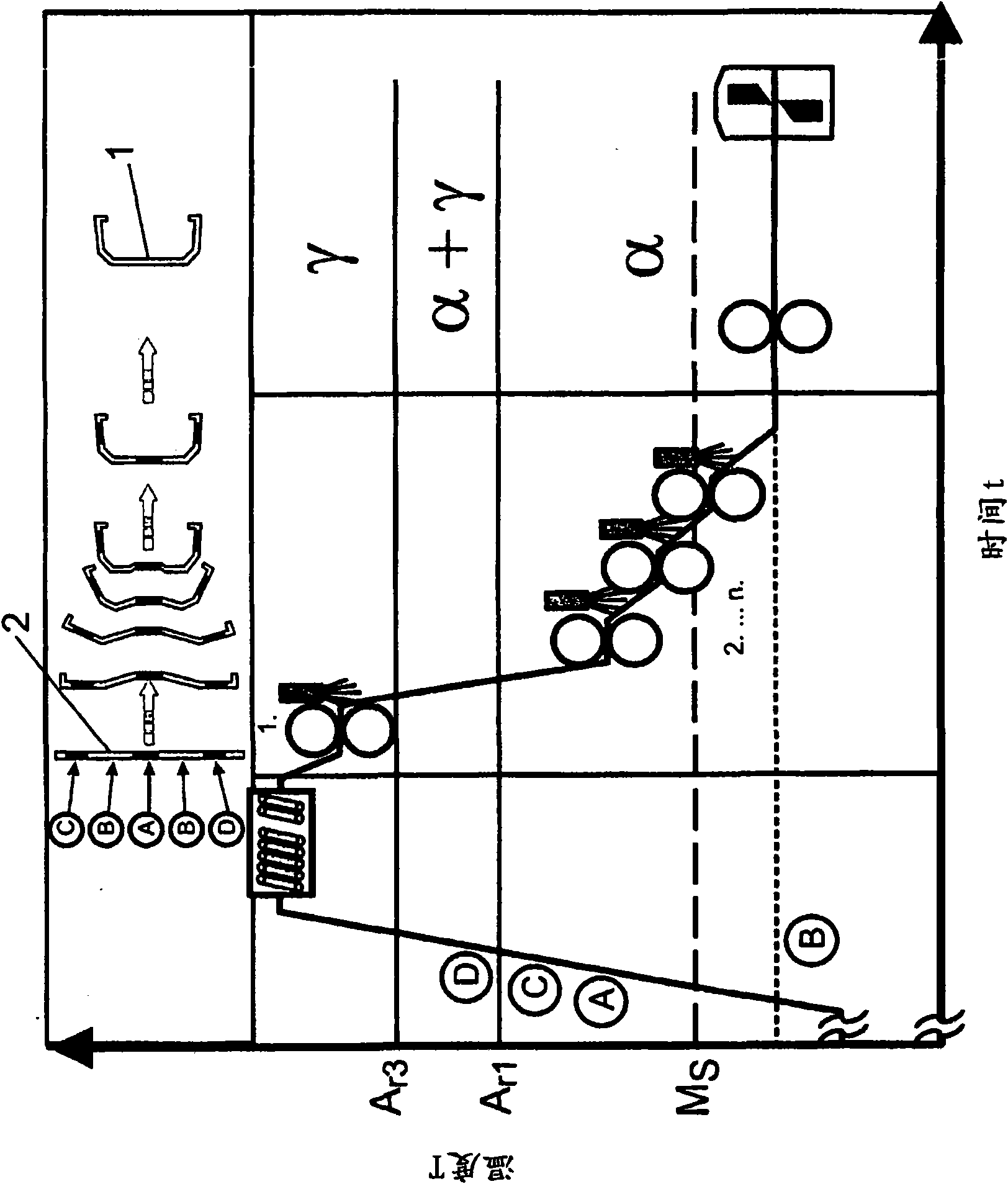

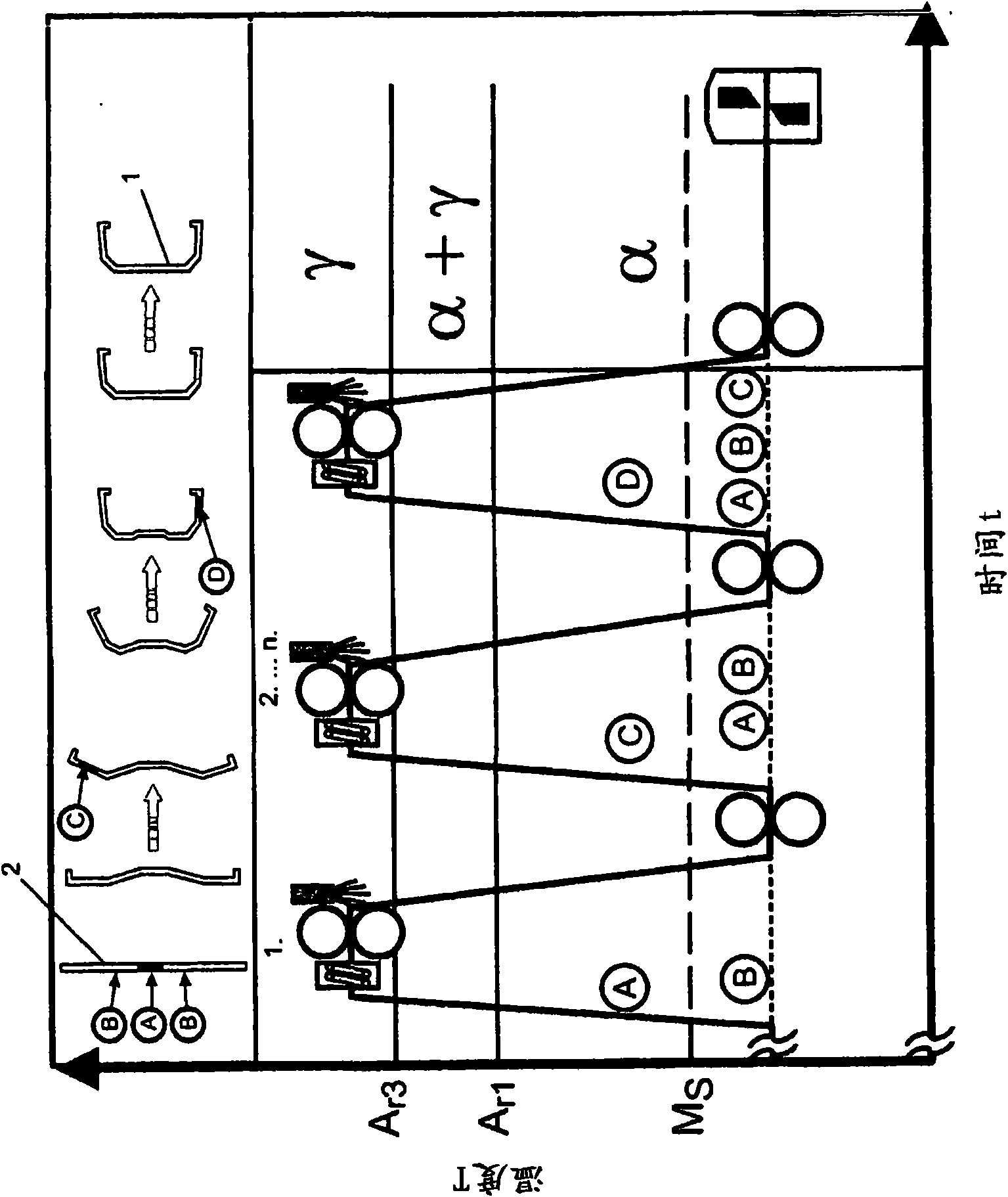

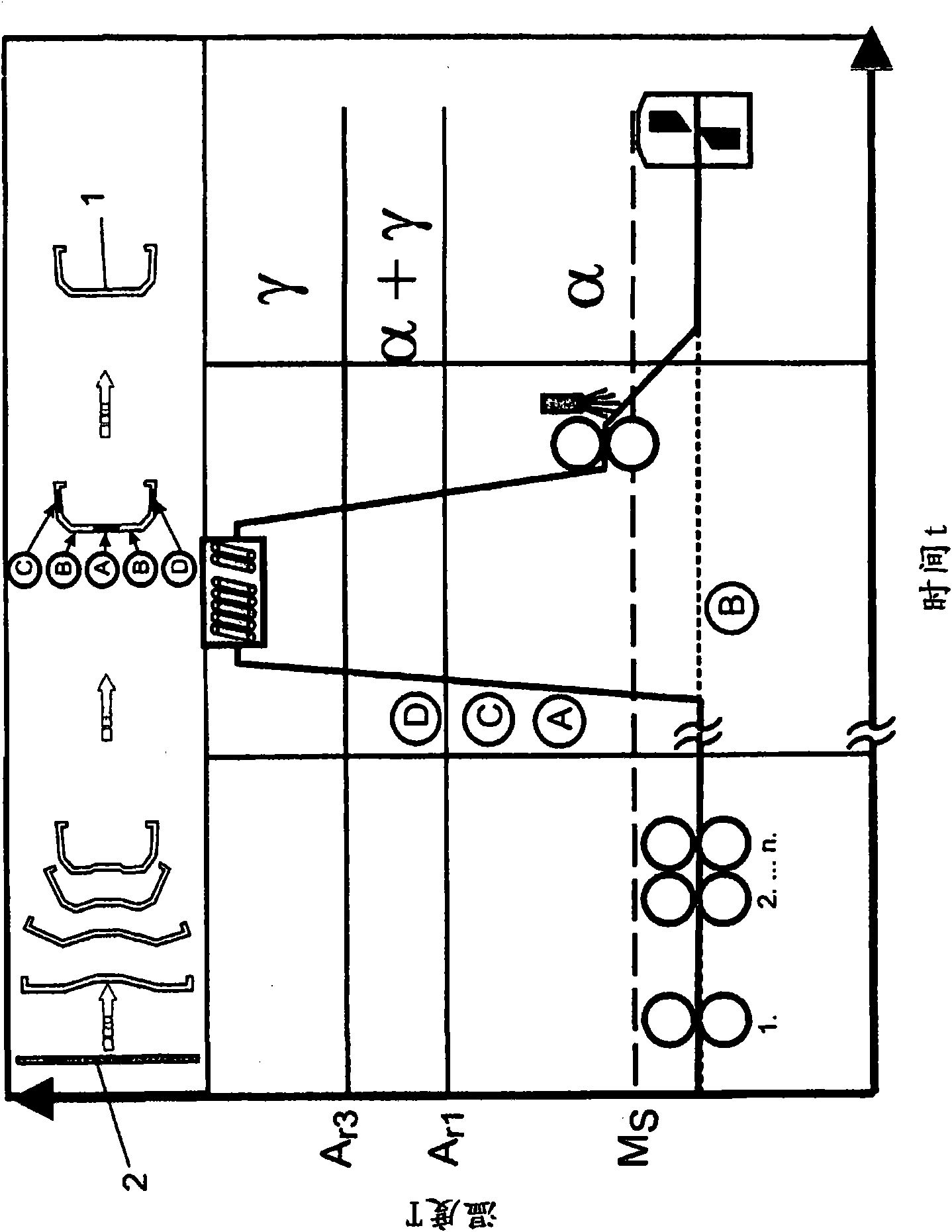

[0067] Combine below Figure 1 to Figure 3 Three different advantageous embodiments of the method for producing a shaped part 1 from a preferably strip-shaped sheet metal semi-finished product 2 are specified. to this end, Figure 1 to Figure 3 Schematically shows the thermomechanical process sequence for producing a shaped part 1 according to a particularly preferred roll-forming method according to the invention in a combined heating and forming process of a sheet metal semi-finished product 2 in a roll-forming device implement.

[0068] The three preferred exemplary embodiments shown here differ in particular from the different process sequences in which the semi-finished sheet metal 2 is heated at least in regions before, during or after the deformation. The graphs each show time-dependent temperature profiles that occur in predetermined (spatially defined) regions A, B, C, D of the sheet metal semifinished product 2 before, during or after the individual forming steps. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com