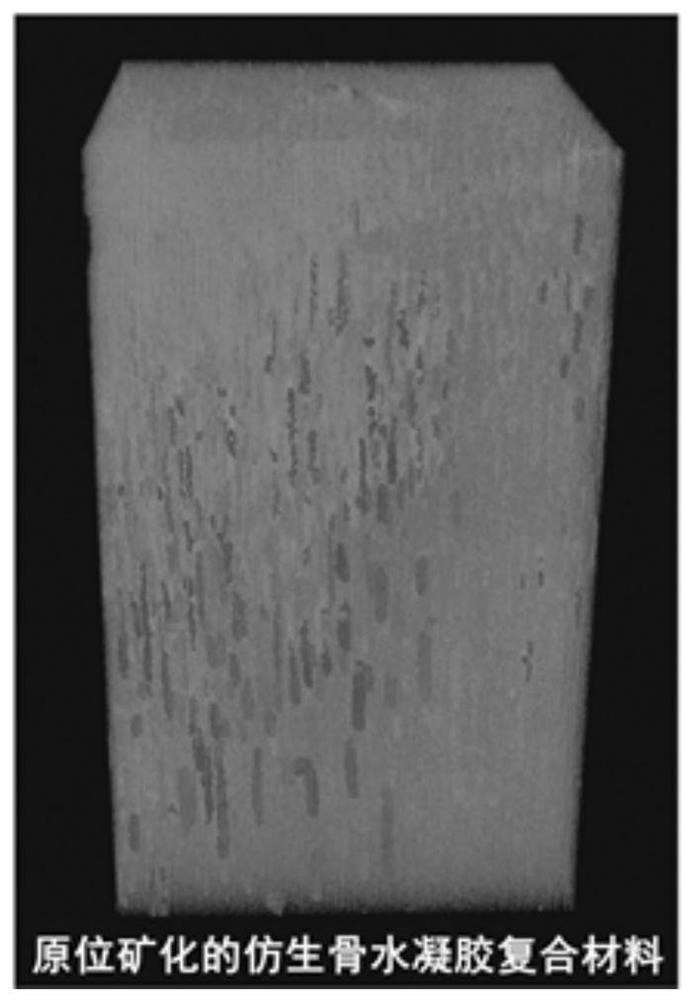

In-situ mineralized bionic bone hydrogel composite material with oriented structure as well as preparation method and application thereof

A technology of in situ mineralization and composite materials, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problem that the mechanical properties cannot match with hard bone tissue, lack of fine control of material structure and surface, and mechanical stability of hydrogel materials It is beneficial to the directional adhesion of cells and the induction of osteogenic differentiation, good osseointegration and mechanical stability, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

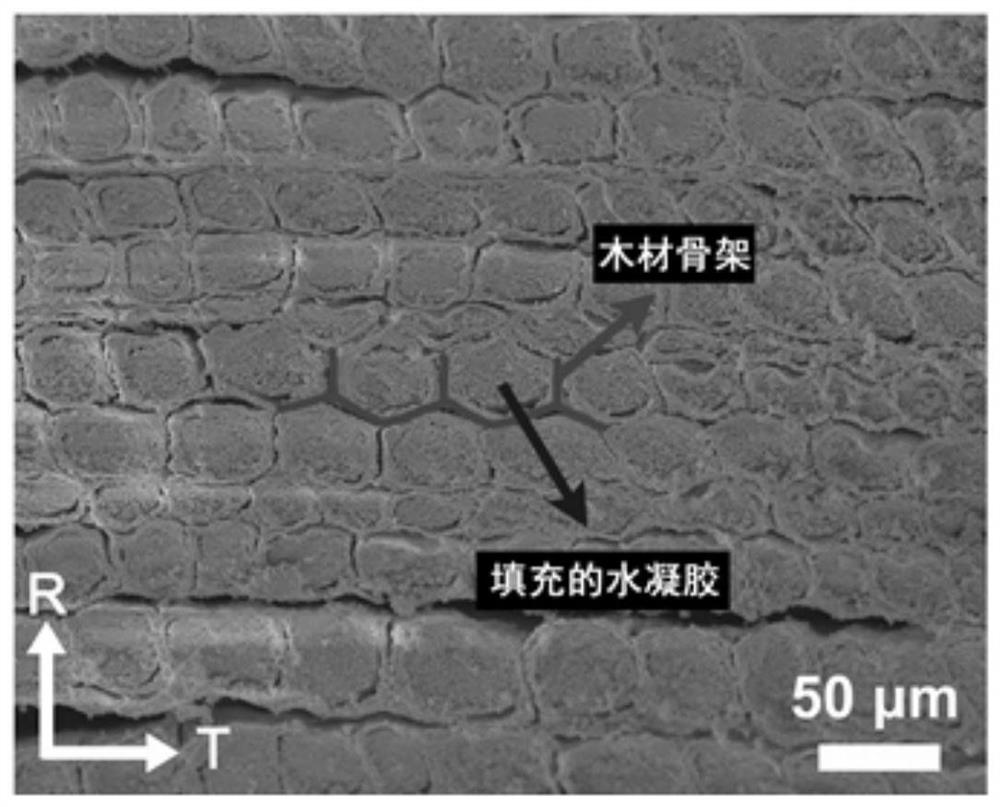

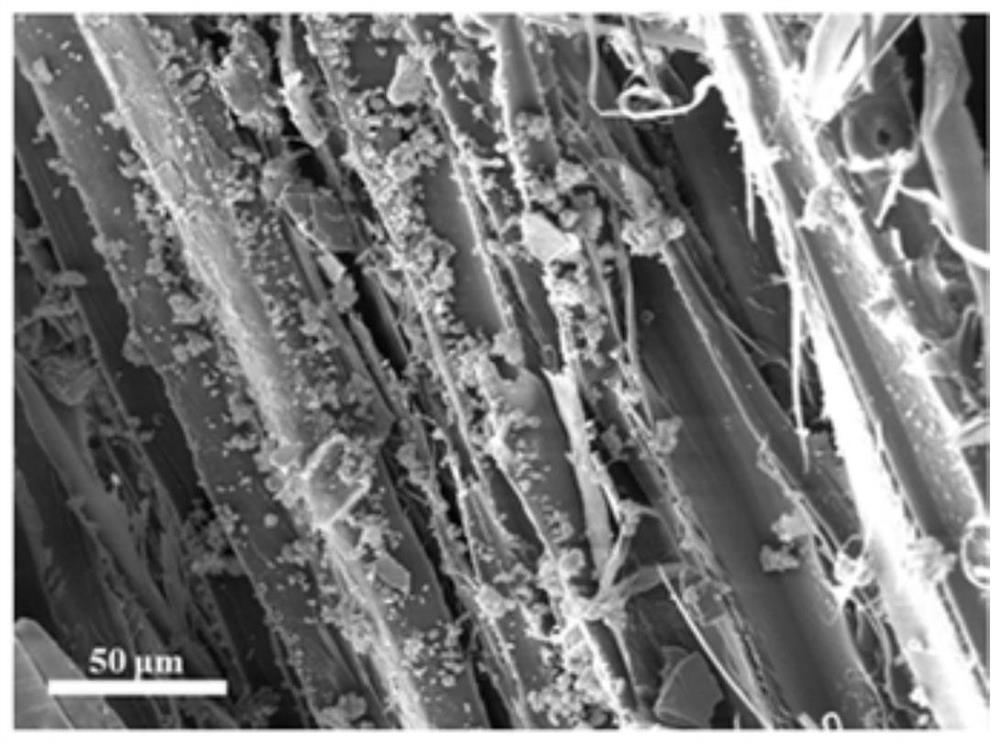

[0050] This embodiment provides a biomimetic bone hydrogel composite material with orientation structure in situ mineralization, the preparation method of which is as follows:

[0051] (1) Delignification treatment of wood chips: the wood chips are cypress, processed into a cube with a thickness of 2 mm and a side length of 10 mm. First, wood chips were immersed in deionized water, treated at 80°C for 1 hour to remove impurities and dust, dried and weighed. According to the solid-to-liquid ratio of 1:35 (g / g), put wood chips into deionized water, add sodium chlorite (0.6g / 1g wood chips) and acetic acid (0.6mL / 1g wood chips), and heat the system to 80 ℃ reaction 6h. After the reaction, the wood chips were taken out, washed three times with deionized water, and dried as templates;

[0052] (2) Place the template prepared in step (1) in an aqueous solution of sodium alginate with a mass fraction of 3%, evacuate to 200 Pa, keep it for 15 minutes, then deflate, repeat 5 times, an...

Embodiment 2

[0055] This embodiment provides a biomimetic bone hydrogel composite material with orientation structure in situ mineralization, the preparation method of which is as follows:

[0056] (1) Delignification treatment of wood chips: the wood chips are eucalyptus, processed into a cube with a thickness of 3 mm and a side length of 10 mm. First, wood chips were immersed in deionized water, treated at 80°C for 1 hour to remove impurities and dust, dried and weighed. According to the solid-to-liquid ratio of 1:30 (g / g), put wood chips into deionized water, add sodium chlorite (0.8g / 1g wood chips) and acetic acid (0.8mL / 1g wood chips), and heat the system to 70 ℃ reaction 6h. After the reaction, the wood chips were taken out, washed three times with deionized water, and dried as templates;

[0057] (2) Place the template prepared in step (1) in a natural collagen aqueous solution with a mass fraction of 5%, evacuate to 100Pa, keep for 20min, then deflate, repeat 7 times, so that the...

Embodiment 3

[0060] This embodiment provides a biomimetic bone hydrogel composite material with orientation structure in situ mineralization, the preparation method of which is as follows:

[0061] (1) Delignified wood chips: the wood chips are beech wood, processed into a cube with a thickness of 5 mm and a side length of 15 mm. First, wood chips were immersed in deionized water, treated at 80°C for 1 hour to remove impurities and dust, dried and weighed. According to the solid-to-liquid ratio of 1:40 (g / g), put wood chips into deionized water, add sodium chlorite (1g / 1g wood chips) and acetic acid (1mL / 1g wood chips), and heat the system to 75°C for reaction 8h. After the reaction, the wood chips were taken out, washed three times with deionized water, and dried as templates;

[0062] (2) Place the template prepared in step (1) in a chitosan aqueous solution with a mass fraction of 2%, vacuumize to 300Pa, keep for 10min, then deflate, repeat 5 times, and fill the chitosan aqueous solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com