Method for simultaneously improving strength and electric conductivity of Cu-Cr-Nb alloy

A cu-cr-nb, alloy strength technology, applied in the field of copper alloy and powder metallurgy materials, can solve the problems of no obvious change in conductivity, no reported strength data, etc., achieve size reduction, optimize alloy composition, and simple process method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: the preparation of alloy A-1 (composition is shown in A in table 1)

[0061] Step 1, using water-cooled copper crucible magnetic levitation smelting, gas atomization method to prepare alloy powder A (the composition of the powder is shown in A-1 in the table, wherein M is a mixture of RE, B, Ti, wherein RE is Ce, La, Sc , Y, the mass is 12.5%, the mass percentage of B is 17%, and the balance is Ti), the melting temperature is 1650±30°C, the median diameter of the prepared powder is 33.7 μm, and the particle size of the powder is less than 75 μm The proportion is 86%.

[0062] Step 2. Preparation of alloy by spark plasma sintering

[0063] Put the alloy powder into the graphite mold, and then place the graphite mold with the alloy powder in the spark plasma sintering equipment; turn on the equipment, vacuumize to the set value, load the pressure and heat up, according to the set sintering temperature, pressure, time The powder is sintered and shaped under...

Embodiment 2

[0068] Embodiment 2: the preparation of alloy A-2 (composition is shown in A in table 1)

[0069] Step 1, powder preparation, with embodiment 1;

[0070] Step 2, powder forming, with embodiment 1;

[0071] Step three, deformation heat treatment

[0072]The deformation heat treatment method is thermal deformation / heat treatment / thermal deformation / secondary heat treatment, the deformation method is rolling, the deformation temperature is 600°C, the total deformation amount of the initial deformation is 40%, the single deformation amount is 2.5%, and the heat treatment temperature is 475 ℃, the time is 120min, the total deformation of the secondary deformation is 40%, the single deformation is 2.5%, the secondary heat treatment temperature is 350 ℃, and the time is 60min.

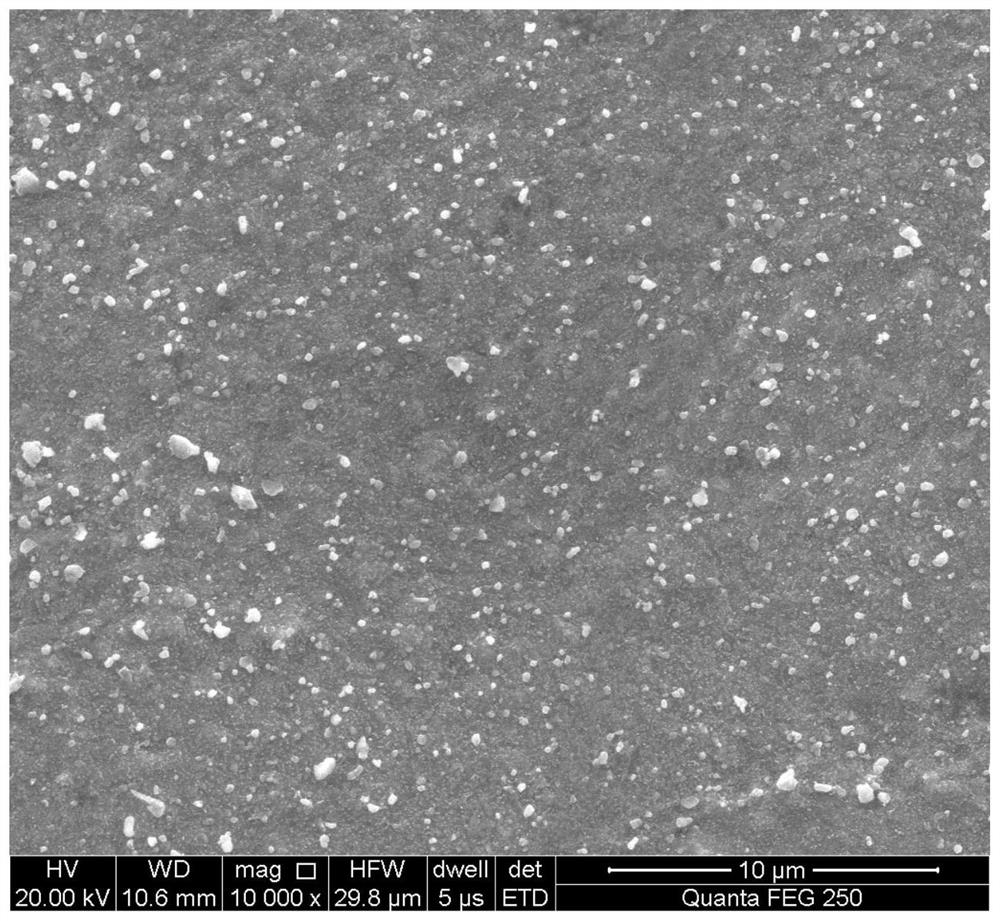

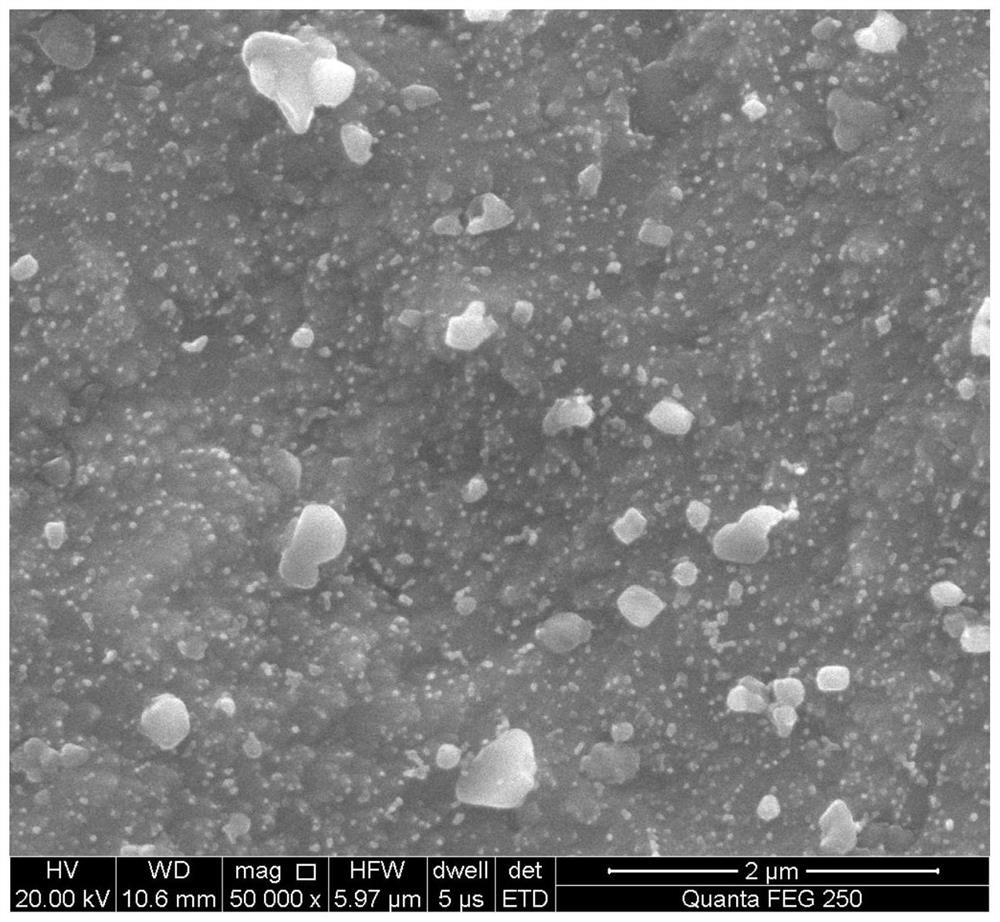

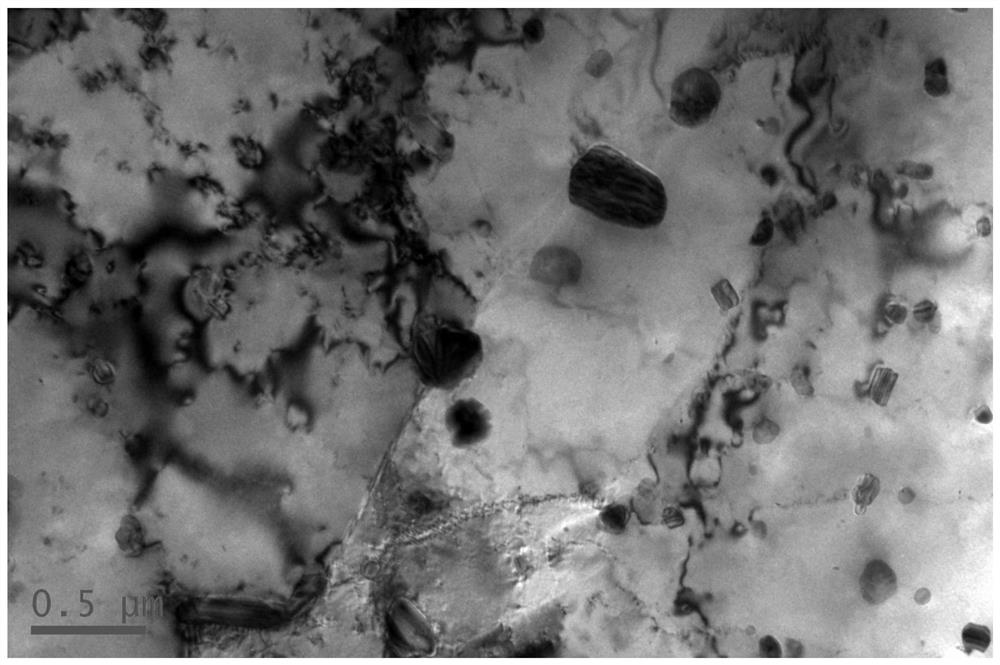

[0073] The microstructure of the as-prepared alloy is as Figure 5-7 , it can be seen from the figure that the multiscale second phase in the alloy is small in size and evenly distributed, and the matrix f...

Embodiment 3

[0075] Embodiment 3: the preparation of alloy A-3 (composition is shown in A in table 1)

[0076] Step 1, powder preparation, with embodiment 1;

[0077] Step 2, powder forming, with embodiment 1;

[0078] Step three, deformation heat treatment

[0079] The deformation heat treatment method is thermal deformation / heat treatment / cold deformation / secondary heat treatment, the deformation method is rolling, the deformation temperature of hot deformation is 600°C, the deformation temperature of cold deformation is room temperature, the total deformation of the initial deformation is 40%, and the single deformation The amount is 2.5%, the heat treatment temperature is 475°C, the time is 120min, the total deformation amount of the secondary deformation is 40%, the single deformation amount is 2.5%, the secondary heat treatment temperature is 350°C, and the time is 60min.

[0080] The microstructure of the as-prepared alloy is as Figure 7-11 , it can be seen from the figure that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com