Case reasoning technology-based damping machine intelligent optimized control method

A control method and intelligent optimization technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve the problem that the control effect of moisture content at the outlet is difficult to meet the process requirements, the moisture content of the inlet tobacco leaves is not detected, and the operation is labor-intensive and other problems to achieve the effect of reducing labor intensity, fine control, and overcoming nonlinearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

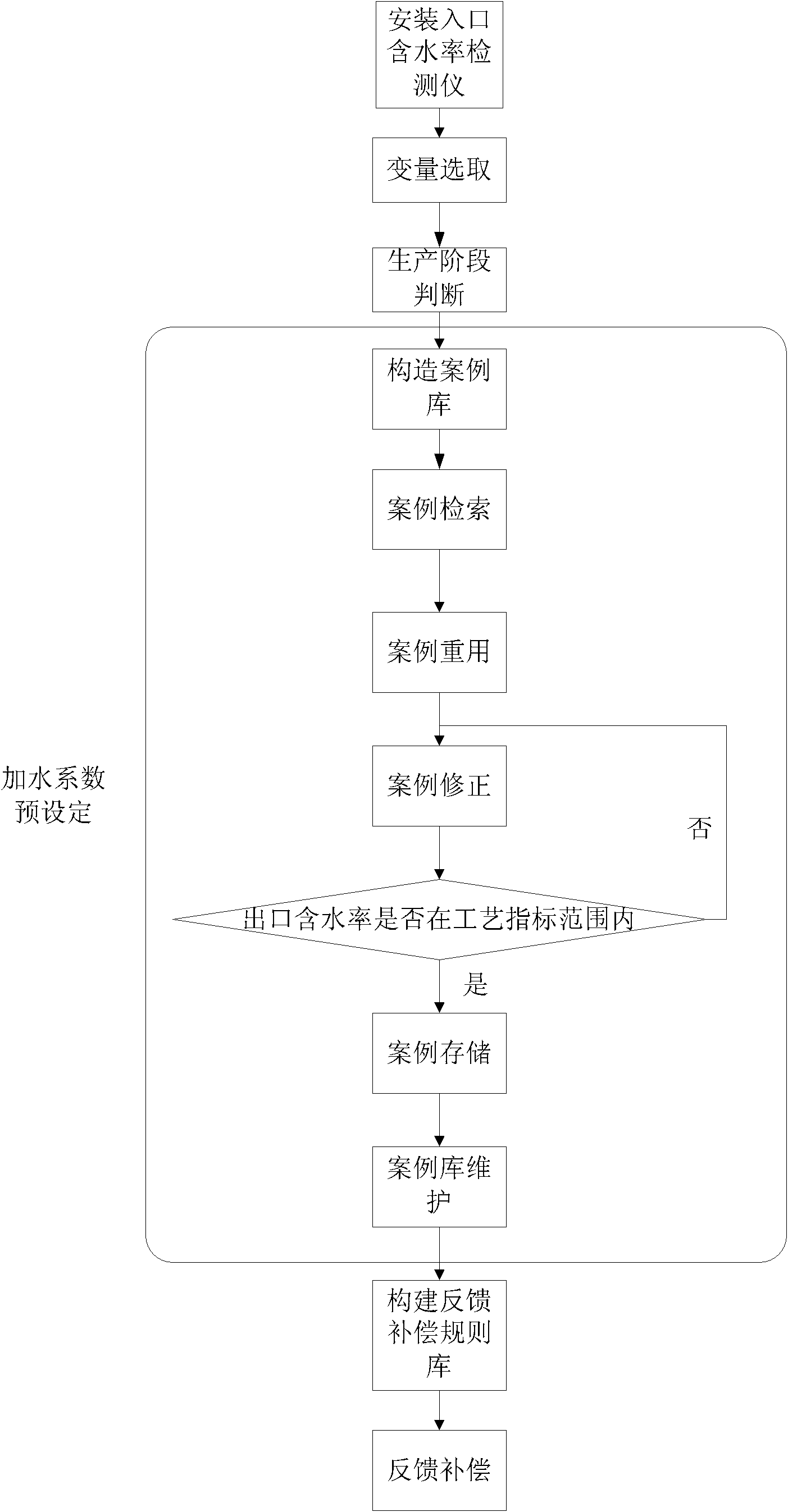

[0036] Such as figure 2 As shown, the present invention is based on the intelligent optimization control method of the moisture regainer of the case reasoning technology, and is characterized in that comprising the following steps:

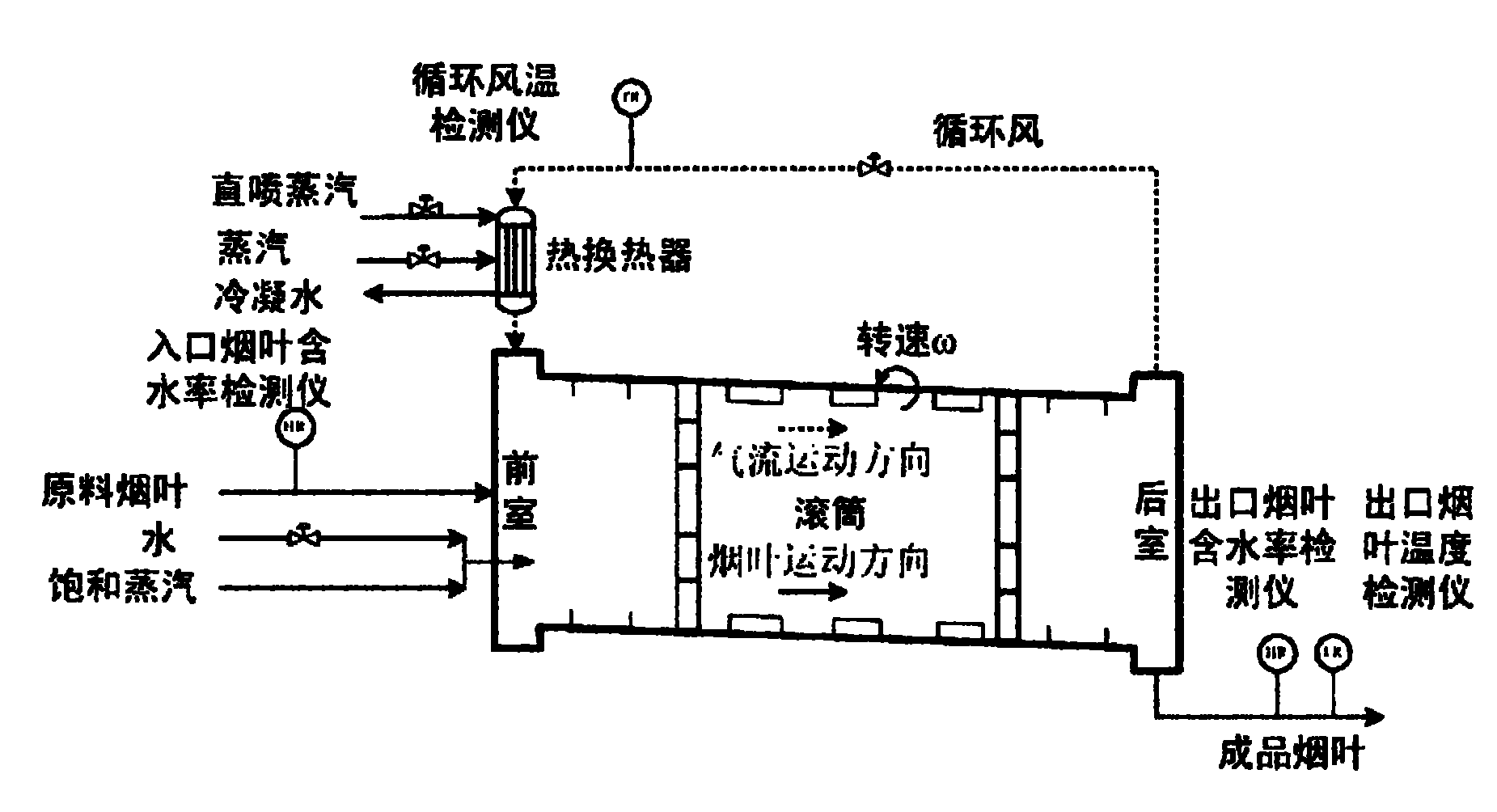

[0037] Install a moisture detector at the entrance of the tempering machine to detect the moisture content of the tobacco leaves at the entrance of the tempering machine;

[0038] The water addition coefficient is selected as the direct manipulated variable, the water flow rate sprayed out by the steam-water mixing nozzle in the damp conditioner is used as the indirect manipulated variable, and the moisture content of the outlet tobacco leaves is used as the controlled variable;

[0039] According to the instantaneous flow of tobacco leaves, the cumulative flow of tobacco leaves and the feeding time information, it is judged whether the current production stage is the beginning stage, the normal production stage or the end stage;

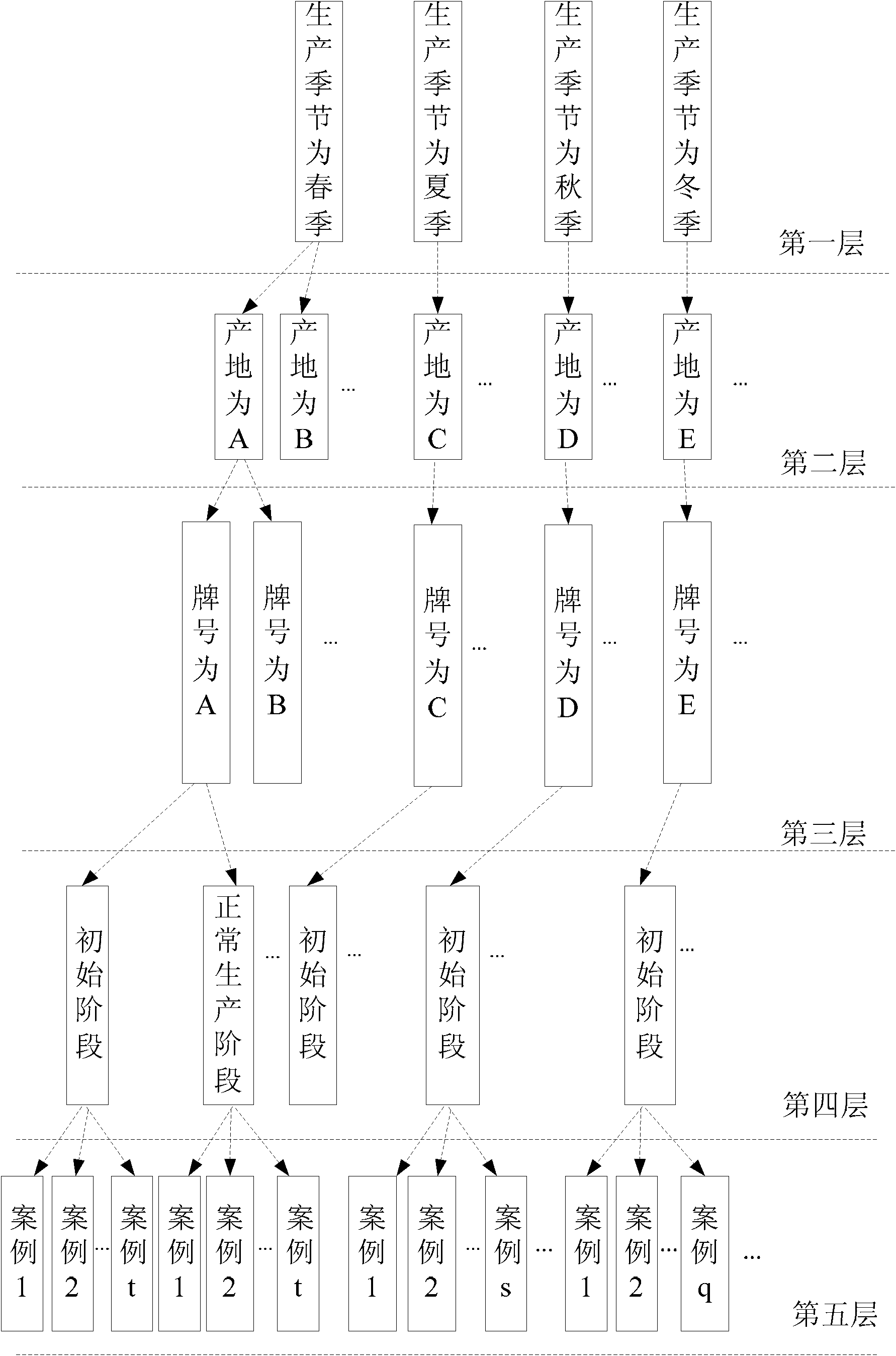

[0040] Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com