Preparation method for film bulk acoustic wave resonator

A thin-film bulk acoustic wave and resonator technology, applied in the direction of impedance network, electrical components, etc., can solve the problems of high surface flatness, lower electrode damage, difficult to prepare thin-film bulk acoustic wave resonator laminated structure, etc., to achieve the preparation process The effect of simplicity and the structural strength of the fabricated device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

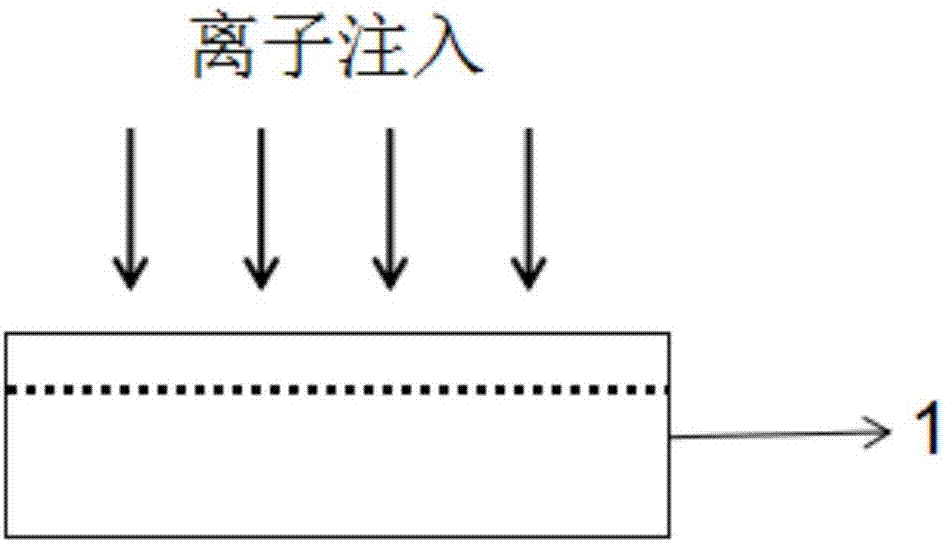

[0029] Step 1. Using an ion implanter to single crystal LiNbO 3 The wafer is implanted with He ions, the implantation energy is 150keV~285kV, and the implantation dose is greater than 2×10 16 ions / cm 2 , injecting He+ in LiNbO 3 A He+ accumulation layer is formed under the wafer surface. The depth of the accumulation layer depends on the implantation energy. The implantation depth is 600-900nm, such as figure 1 As shown, the dotted line indicates the location of the aggregation layer.

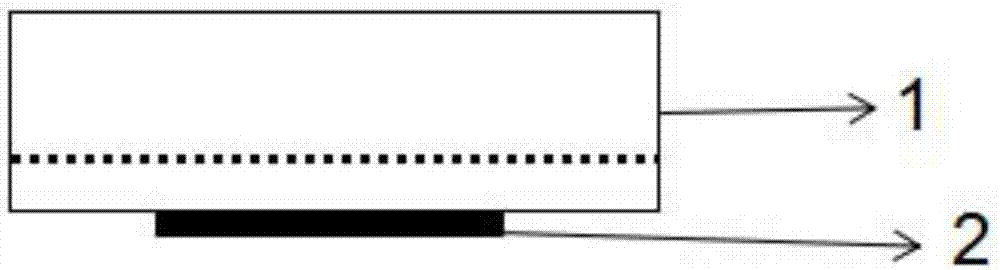

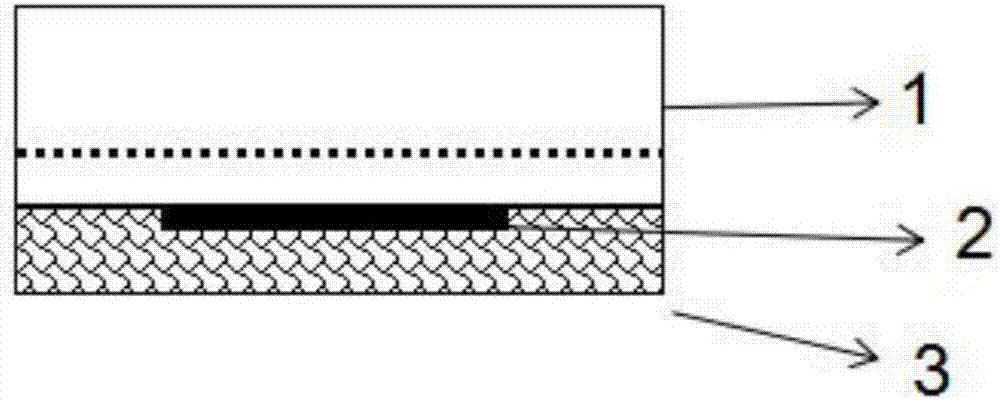

[0030] Step 2, in LiNbO 3 Inject a thin layer of Ti with a thickness of 10nm as the adhesion layer, and then grow a thin layer of Al with a thickness of 50-200nm on the thin layer of Ti as the lower electrode. The growth methods of the Ti thin layer and the Al thin layer include electron beam evaporation, Resistance evaporation, DC sputtering, magnetron sput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com