Reducing bent pipe and pumping equipment with same

A technology for pumping equipment and pipe bends, applied in mechanical equipment, pipes/pipe joints/pipe fittings, pumps, etc., can solve the problems of low service life of variable-diameter bends, delay in construction progress, and large resistance at bends, to avoid Local wear is too fast or material accumulation, reducing pressure loss, reducing the effect of erosion wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

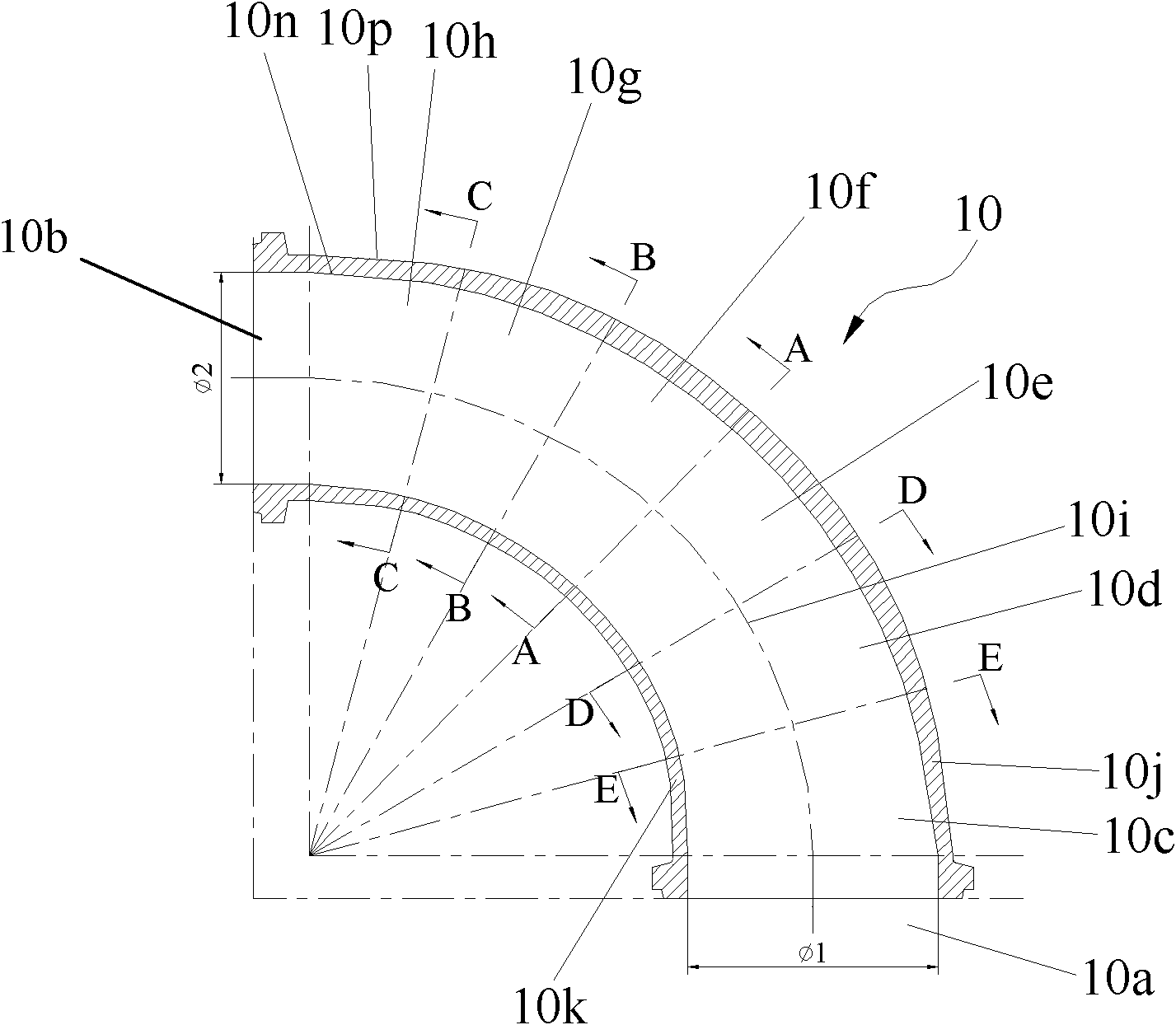

[0025] In the following, the embodiments of the present invention will be described by comparing the reduced-diameter elbows in the prior art with reference to the accompanying drawings and specific examples.

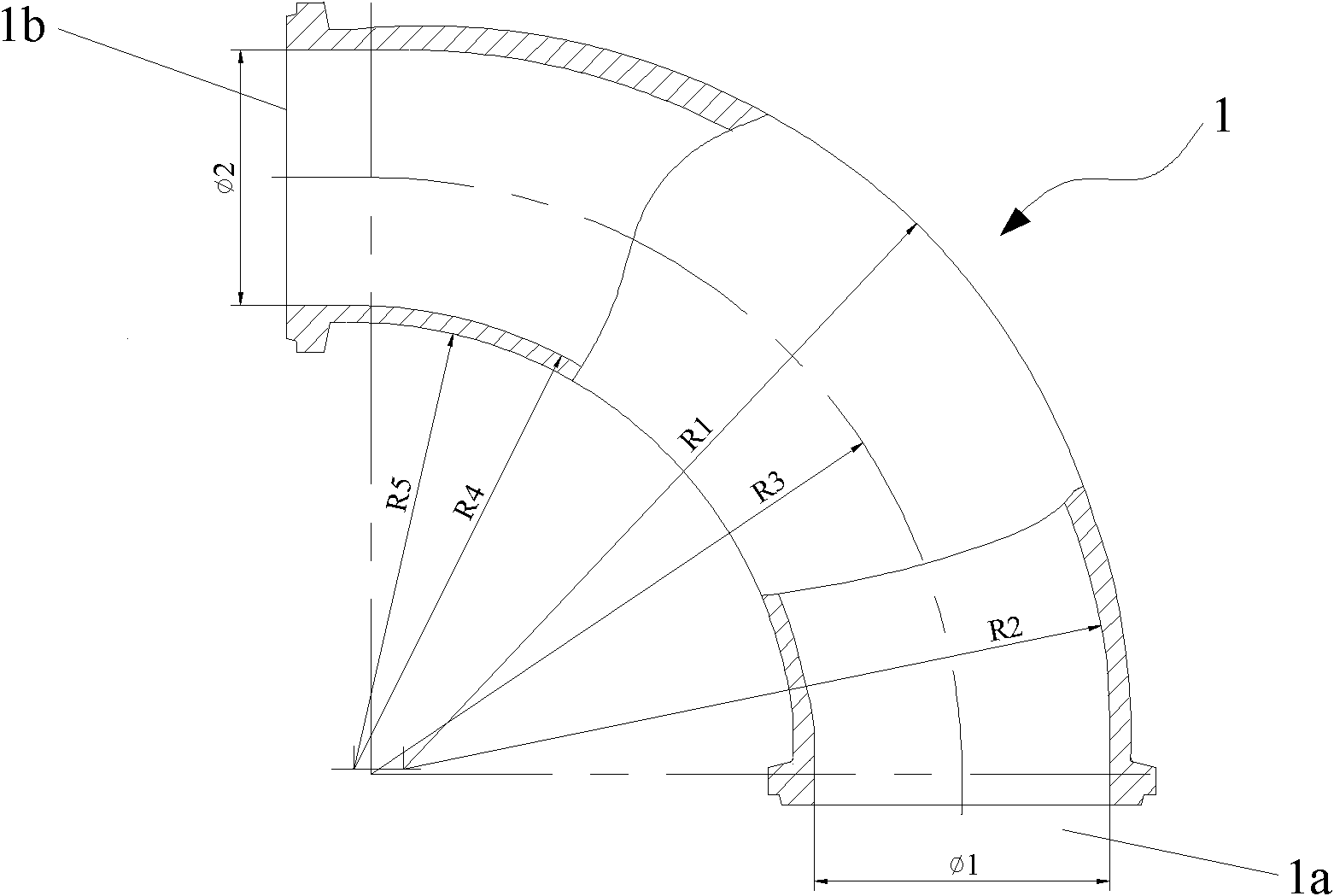

[0026] first of all, yes figure 1 The structure of a reducing elbow used in the prior art shown in .

[0027] Such as figure 1 As shown, the structure of the reducing elbow 1 in the prior art is as follows:

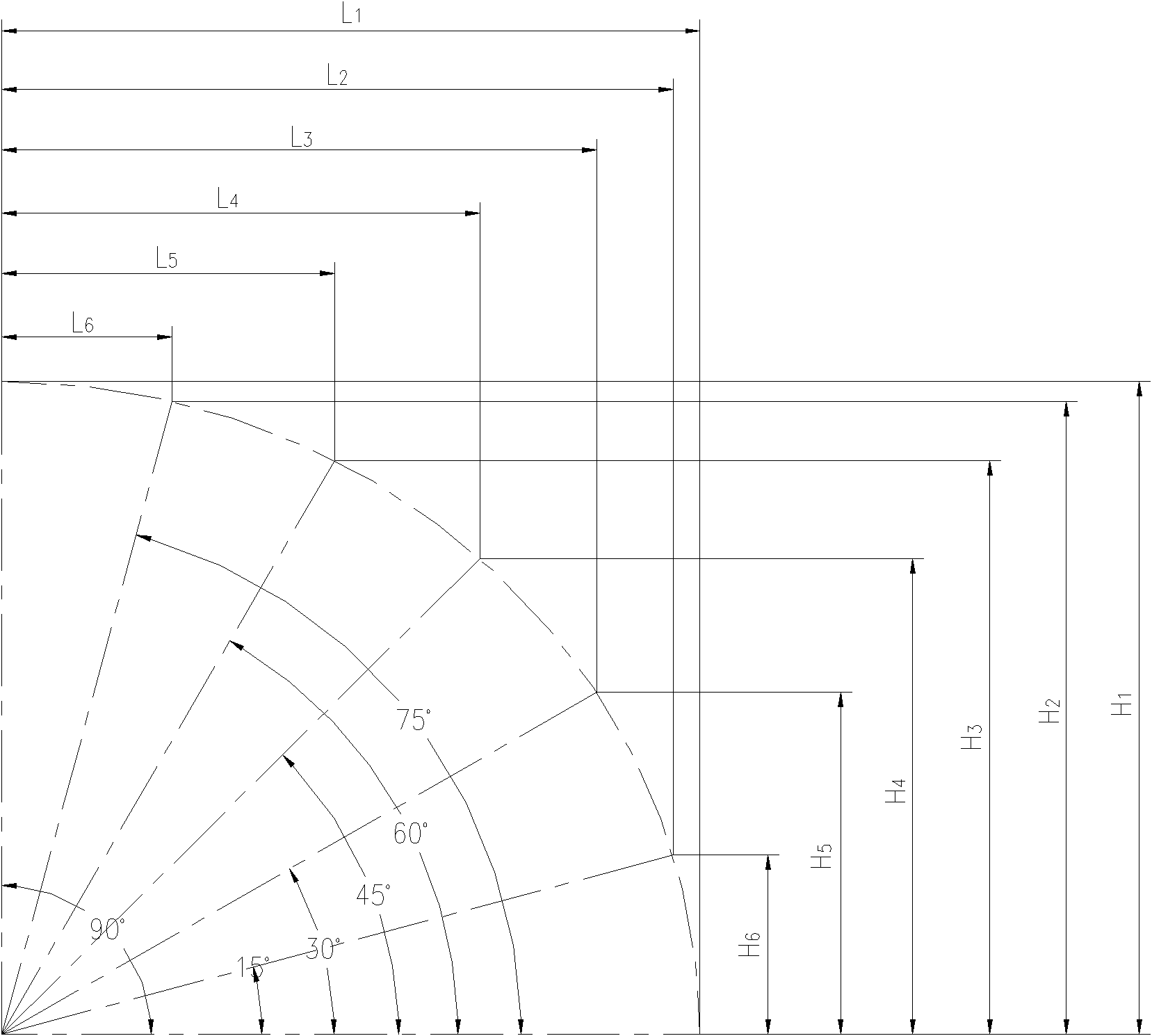

[0028] The elbow 1 has an input end 1a with a large inner diameter (having an inner diameter Φ1, such as 175mm) and a small inner diameter output end 1b (with an inner diameter Φ2, such as 150mm), and the inner diameter of the elbow 1 is continuously reduced from the input end 1a to the output end 1b. small. The radius of curvature R1 of the outer pipe wall near the outside of the elbow 1 and the radius of curvature R2 of the inner pipe wall near the outside have a common center O1, and the radius of curvature R4 of the inner pipe wall near the outside of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com