Material blocking plate and lifting machine with same

A material blocking plate and hoist technology, which is applied in the direction of conveyors, transportation and packaging, metal layered products, etc., can solve the problems of easy damage of the material blocking plate, short service life, poor material blocking effect, etc., and achieve the material blocking effect Good, long service life, reduce the effect of erosion wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with specific examples:

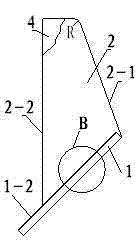

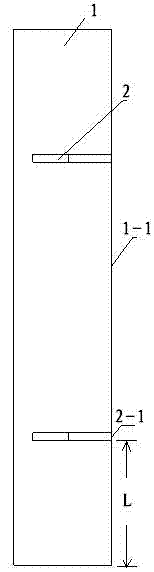

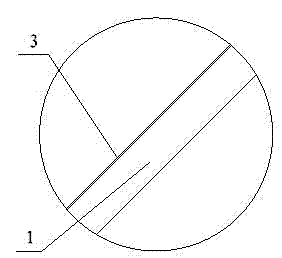

[0021] like figure 1 , figure 2 and image 3 The shown guide plate includes a baffle 1. Two guide plates 2 are arranged laterally on the baffle 1. The guide plate 2 is a trapezoid. The upper surface of the baffle 1 is provided with a wear-resistant layer 3. The guide plate A wear-resistant layer 4 is provided on the outer surface of The lower part of one of the guiding edges 2-1 is flush with the outer edge 1-1 of the baffle plate 1, and the other guiding edge 2-2 of the guiding plate 2 intersects with the working surface 1-2 of the baffle plate 1 at an included angle α. is 115°, and the top corner of the leading edge 2-1 that is flush with the outer edge 1-1 of the baffle 1 is an arc angle with a radius R of 30 mm.

[0022] like Figure 4 , Figure 5 and Image 6 As shown, the elevator includes a casing 5, a discharge port 6 of the elevator, a hopper 7 and a baff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com