Steel plate bending equipment

A steel plate and bending technology, which is applied in the field of steel plate bending equipment, can solve the problems of uneven quality of curved steel plates, difficult control of arc bending, and extra workload, so as to improve kinetic energy utilization efficiency, simplify force, and reduce useless work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

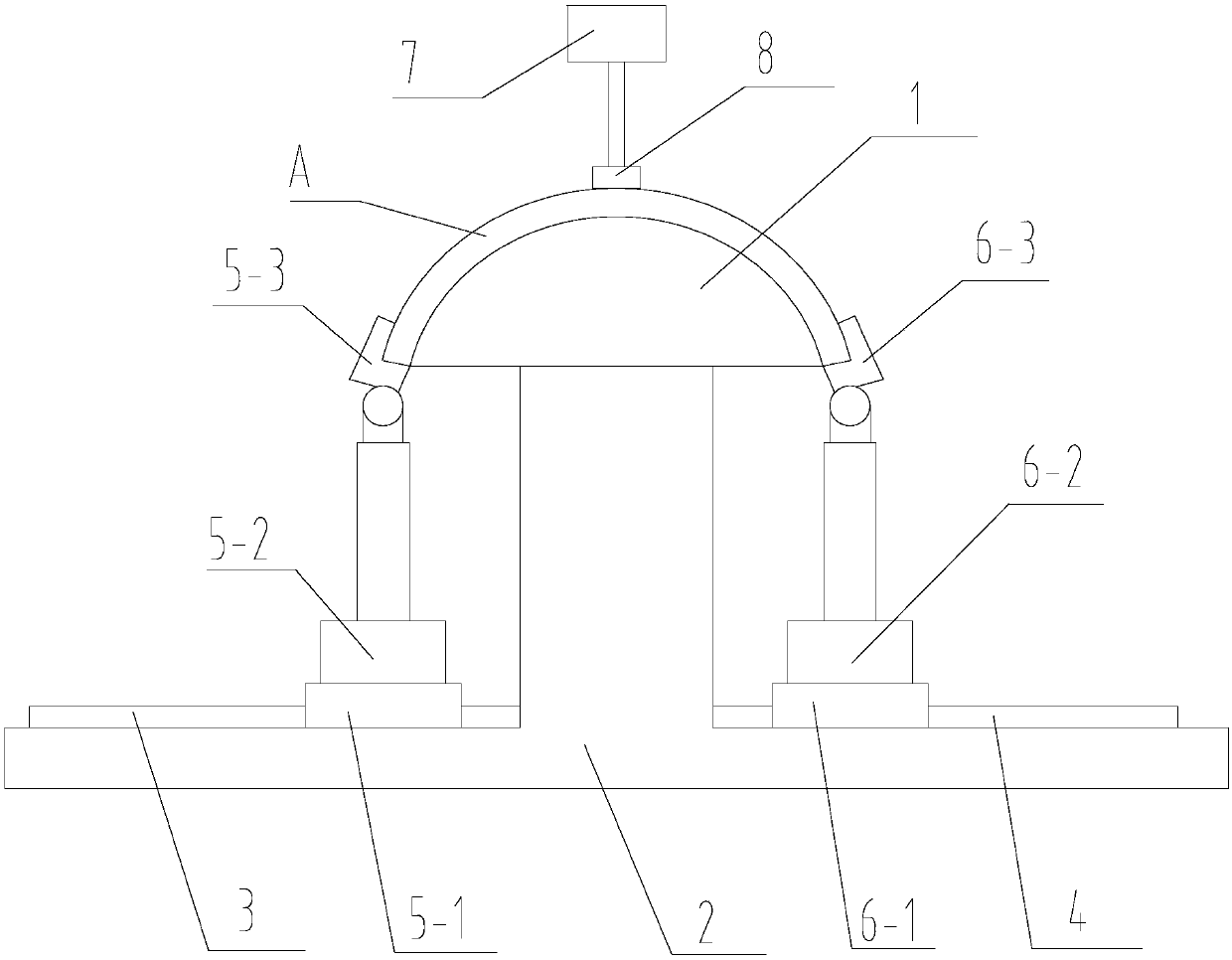

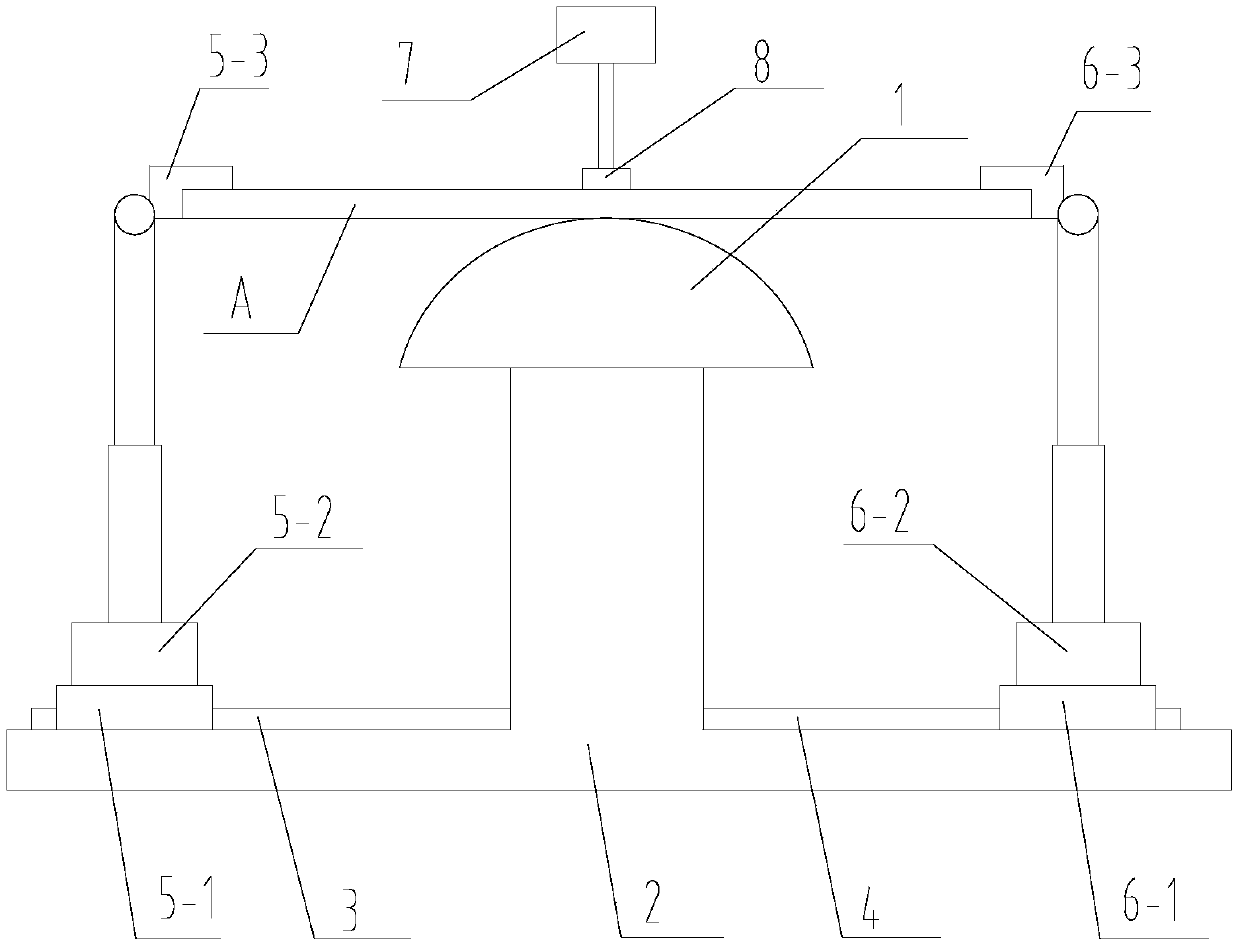

[0021] refer to figure 1 , a steel plate bending equipment proposed by the present invention includes: a punch 1 , a first press-down mechanism, a second press-down mechanism and a base 2 .

[0022] The upper surface of the punch 1 is a curved surface that fits the inner surface of the bent steel plate, and the punch 1 is fixedly installed on the base 2 . A first track 3 and a second track 4 are respectively provided on the base 2 on opposite sides of the punch 1 .

[0023] The first depressing mechanism comprises a first moving frame 5-1, a first cylinder 5-2 and a first manipulator 5-3, the first moving frame 5-1 is slidably installed on the first track 3, and the first cylinder 5-2 Installed on the first moving frame 5-1, the first manipulator 5-3 is connected with the first air cylinder 5-2, and the first air cylinder 5-2 is used to drive the first manipulator 5-3 to move up and down.

[0024] The second depressing mechanism comprises a second moving frame 6-1, a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com