Inclined wedge regulating and spacing mechanism for air conditioner fin die

A technology of air-conditioning fins and limiting mechanisms, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of positioning failure, easy breakage of adjustment screws, and easy loosening of screws. Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

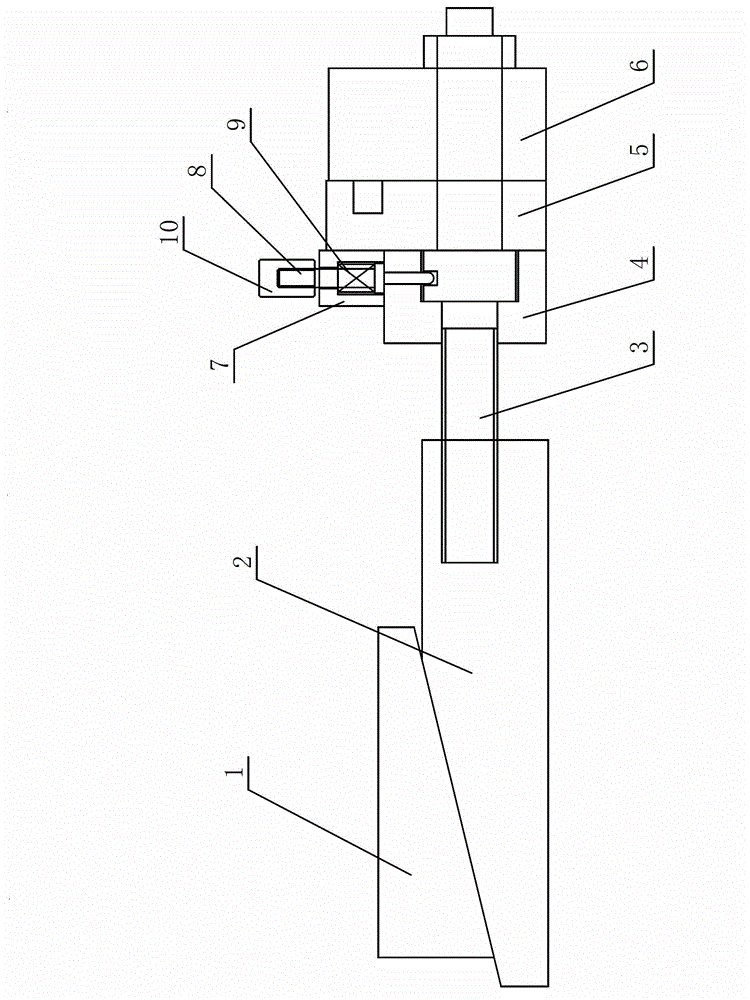

[0011] see figure 1 as shown, figure 1 It is a structural schematic diagram of the air-conditioning fin mold wedge adjustment limit mechanism provided in Embodiment 1 of the present invention.

[0012] In this embodiment, an air-conditioning fin mold wedge adjustment limit mechanism includes a first wedge block 1 and a second wedge block 2 that cooperate with each other, and an adjustment screw 3 is connected to the second wedge block 2, The adjusting screw 3 is installed on the adjusting screw fixing block 4, and one side of the adjusting screw fixing block 4 is provided with a display fixing block 5, and a digital display 6 is installed on one side of the display fixing block 5, and the adjusting screw The top of the fixed block 4 is provided with a limit nail fixed block 7, a limit nail 8 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com