Improved structure of compact type wind power generating set

A technology for wind turbines and generators, which is applied in the control of wind turbine components, wind motor combinations, and wind engines. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

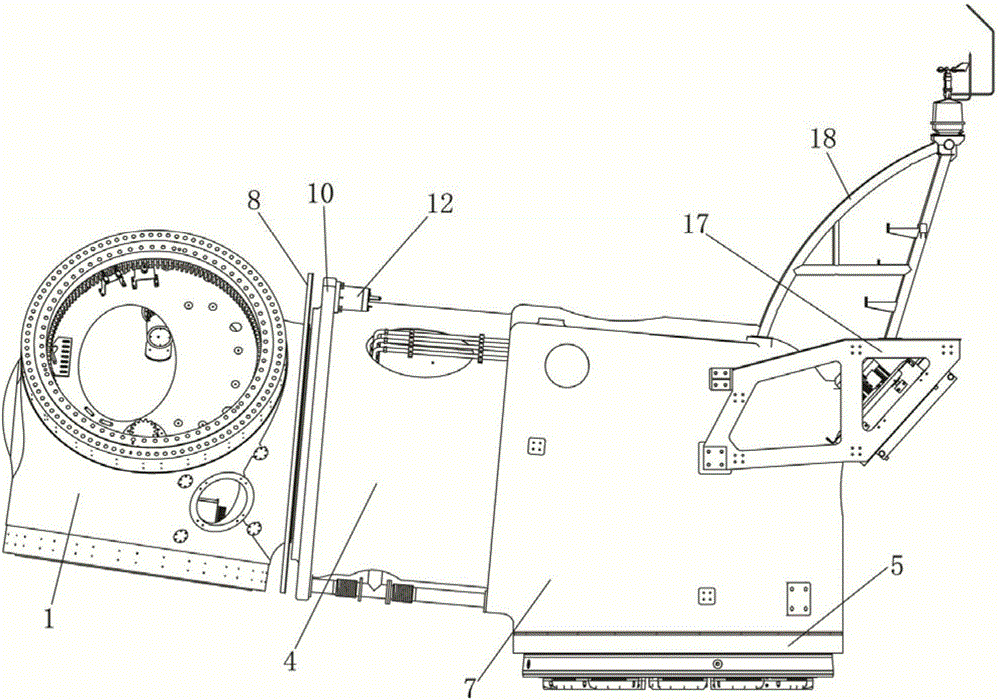

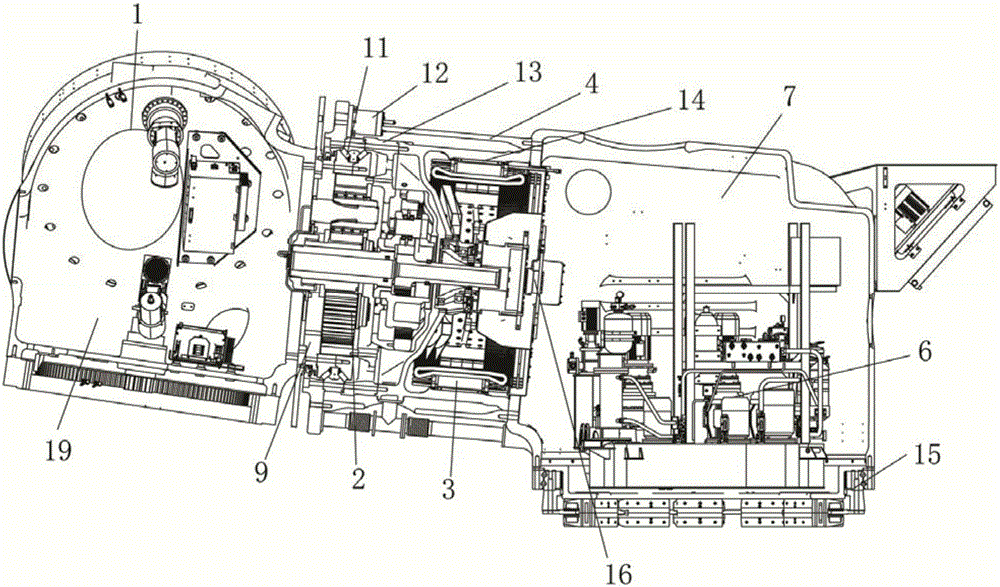

[0021] Such as figure 1 and figure 2 As shown, the improved structure of the compact wind power generating set described in this embodiment includes at least one rotor blade (not shown in the figure), hub 1, gearbox 2, generator 3, drive train casing 4, yaw Component 5 and engine room seat 7 with built-in hydraulic pressure, lubrication and integrated cooling system 6. The hub 1 is equipped with a pitch bearing 19. The pitch system is the same as that of a traditional wind power generating set. It adopts an electric pitch system with internal gear meshing transmission, and is driven by a pitch motor through a pitch gearbox. The outer wall of the wheel hub 1 and its components can withstand wind, sun and rain without fairing. The rotor blades are connected to the hub 1 through pitch bearings 19 . The hub 1 is bolted to the inner ring of the rotor bearing 11 of the gear box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com