Locomotive fixation rolling test rack traction indicator table

A rolling test bench and traction force technology, which is applied in the direction of measuring the traction/propulsion power of vehicles, can solve the problems of poor universality of special couplers, no anti-break protection structure, and limitation of coupler telescopic distance, so as to achieve flexible adjustment of coupler expansion and easy control. The effect of moving the locomotive and improving the life of the reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is further described in conjunction with accompanying drawing:

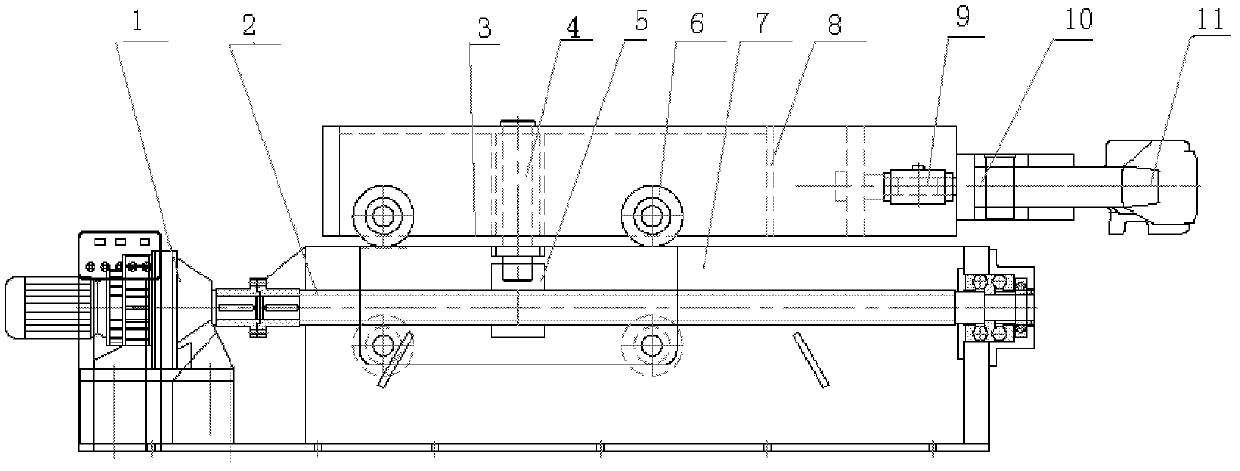

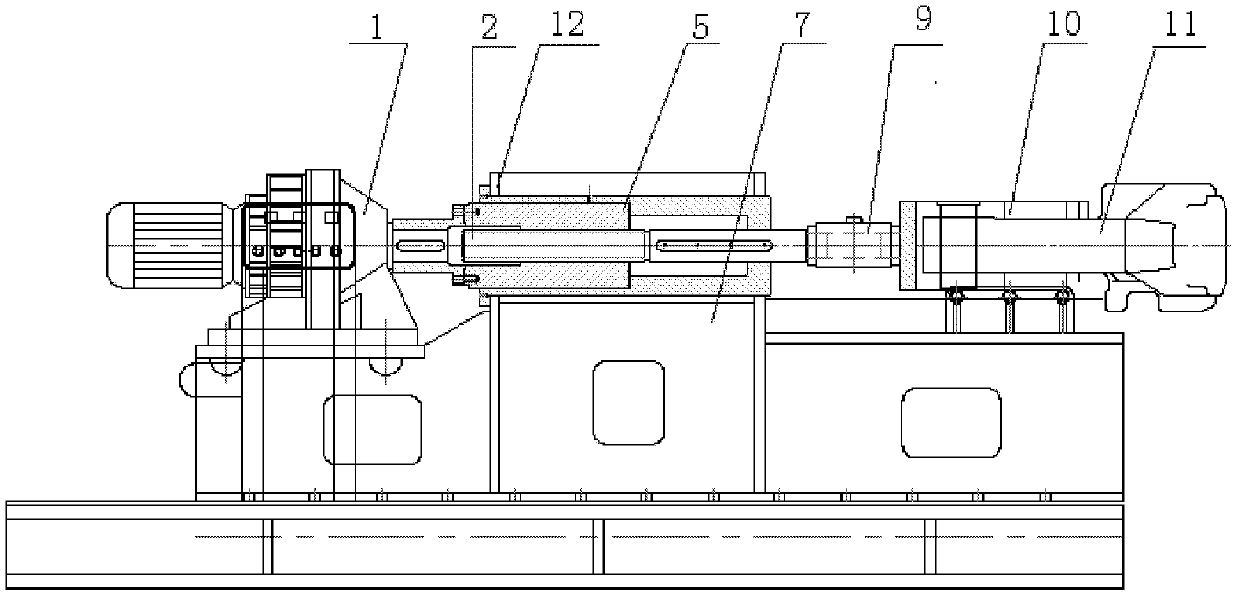

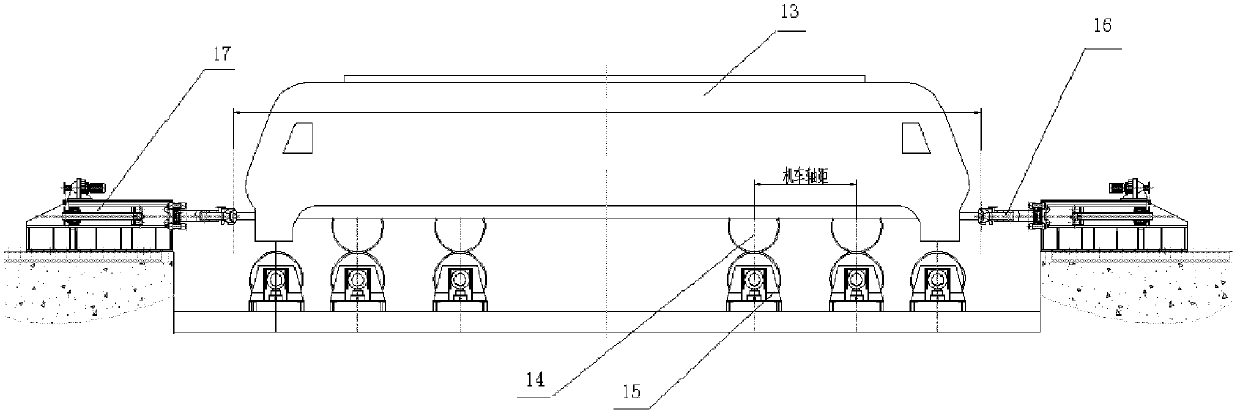

[0044] Existing traction gauges such as figure 1 As shown, the traction meter platform is divided into upper and lower parts, the upper part is composed of special coupler 11, traction rod 10, load cell 9, mobile frame 8, guide wheel 6, force transmission pin 4, etc.; the lower part is composed of reducer 1. Screw 2, nut 5, frame 7, etc.; the upper part is connected with the lower nut 5 through the force transmission pin 4, the screw 2 rotates to drive the nut 5 to move linearly, and the upper and lower parts are connected through the force transmission pin 4, The guide wheel 6 moves horizontally along the guide plate 3 and transmits horizontal force. Speed reducer 1 drives screw rod 2 to rotate, and nut 5 reciprocates in a straight line, and force transmission pin 4 on nut 5 drives mobile frame 8, load cell 9, traction rod 10, special coupler 11 to telescopically move, and the pus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com