Combined type hydraulic cylinder with floating cylinder barrel

A combined, hydraulic cylinder technology, applied in the direction of fluid pressure actuation devices, etc., can solve the problem that the hydraulic cylinder is difficult to meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

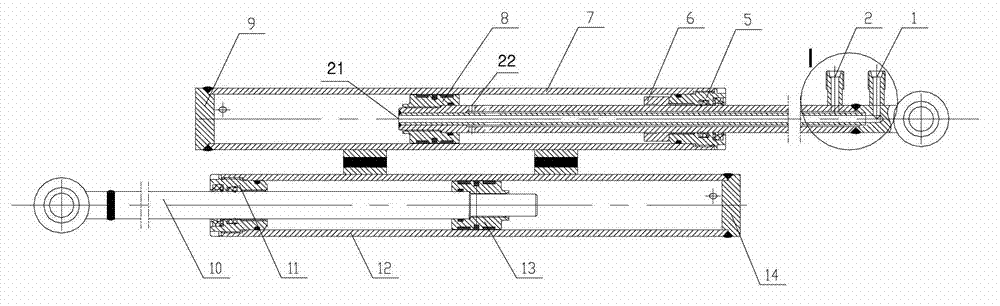

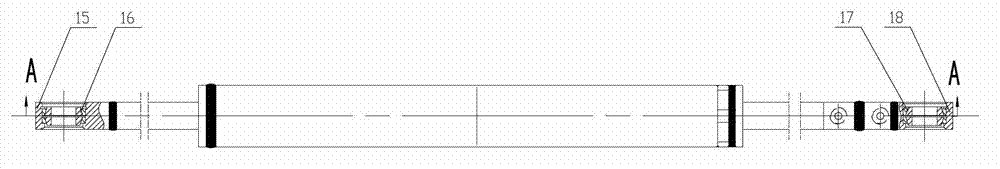

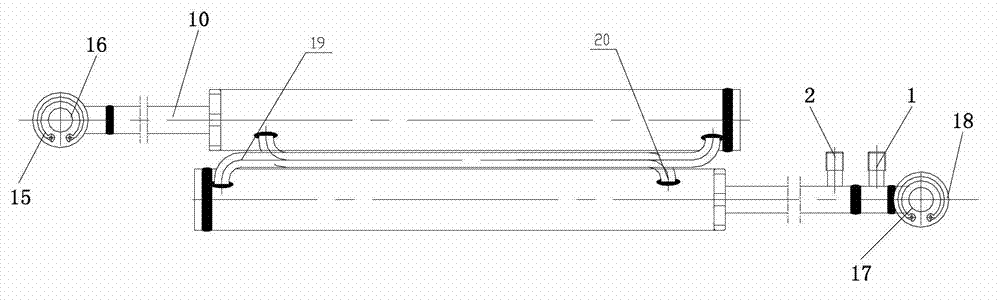

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

[0019] see Figure 1-6 , the combined hydraulic cylinder with floating cylinder, including the oil inlet piston rod, the combined cylinder and the non-oil inlet piston rod; the combined cylinder includes the oil inlet cylinder 7, the non oil inlet cylinder barrel 12, large cavity oil pipe 19 and small cavity oil pipe 20; the piston rod of the oil inlet end and the piston rod of the non-oil inlet end are respectively combined with the oil inlet end cylinder 7 and the non-oil inlet end cylinder 12 to form the oil inlet hydraulic cylinder and It is not a hydraulic cylinder at the oil inlet end, and the piston rod at the oil inlet end is provided with a large cavity oil port 21 and a small cavity oil port 22, wherein the large cavity oil port 21 is connected to the large cavity of the oil inlet cylinder 7, and the small cavity oil port 22 The small chamber connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com