A Method of Establishing Heat Source Model for Laser-arc Hybrid Welding

A heat source model and composite welding technology, applied in laser welding equipment, welding equipment, 3D modeling, etc., can solve the problems of difficult secondary development of heat source models, difficult to popularize and apply, etc., to shorten the test period and reduce the difficulty of engineering application. , reduce the effect of useless work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: A method for establishing a laser-arc hybrid welding heat source model

[0039] In order to realize the purpose of the present invention, the present invention adopts the Nd:YAG laser-MIG electric arc compound welding method to carry out the test, the laser is a continuous laser, and according to the test requirements, a high-power fiber laser and a digital pulse MIG welding gun are used to cooperate to achieve the purpose of compound welding; KUKA The robot completes the movement of the heat source, and the CNC workbench controls the movement of the workpiece; according to the test requirements, a welding fixture is designed to fix the workpiece to complete the welding, thus providing a method for establishing a heat source model for laser-arc hybrid welding. The specific steps are as follows:

[0040] (1) Establish a three-dimensional finite element mesh model:

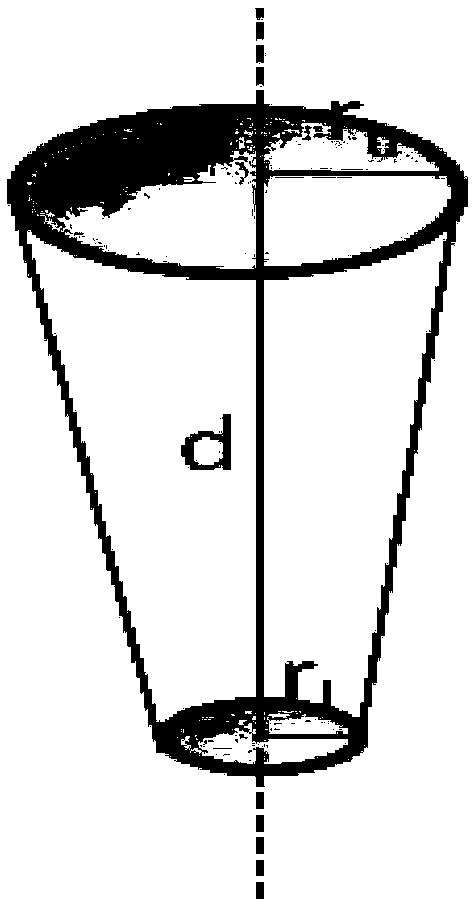

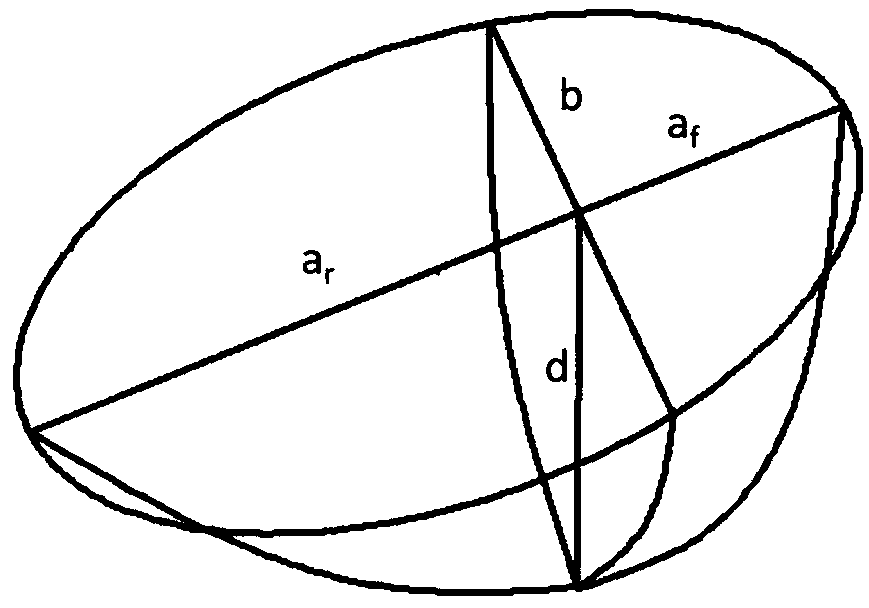

[0041] First, establish the geometric model of the workpiece in the 3D modeling software, an...

Embodiment 2

[0060] Example 2: Effect verification experiment of a method for establishing a laser-arc hybrid welding heat source model

[0061] In this embodiment, laser-arc hybrid welding is used to carry out overlay welding on the surface of Q345D steel plate, and the welding wire is 304 stainless steel welding wire. The specific steps are as follows:

[0062] (1) Establish a three-dimensional finite element mesh model:

[0063] The geometric model of the workpiece is established by 3D modeling software, and then imported into the meshing software for meshing. The meshing uses hexahedral elements, and at the same time adopts a division method that is dense near the weld and sparse away from the weld. The total number of volume nodes is 39325, the total number of units is 34560.

[0064] (2) Import the grid model into Simufact.welding software to establish a heat source model:

[0065] Adopt a kind of establishment method of laser-arc hybrid welding heat source model provided by the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com