Gas scrubbers for gas generators

A technology of coal gas generator and coal gas, which is applied in the manufacture of combustible gas, purification of liquid washing gas, petroleum industry, etc., and can solve problems such as safety accidents, speeding up, and failure to send out gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

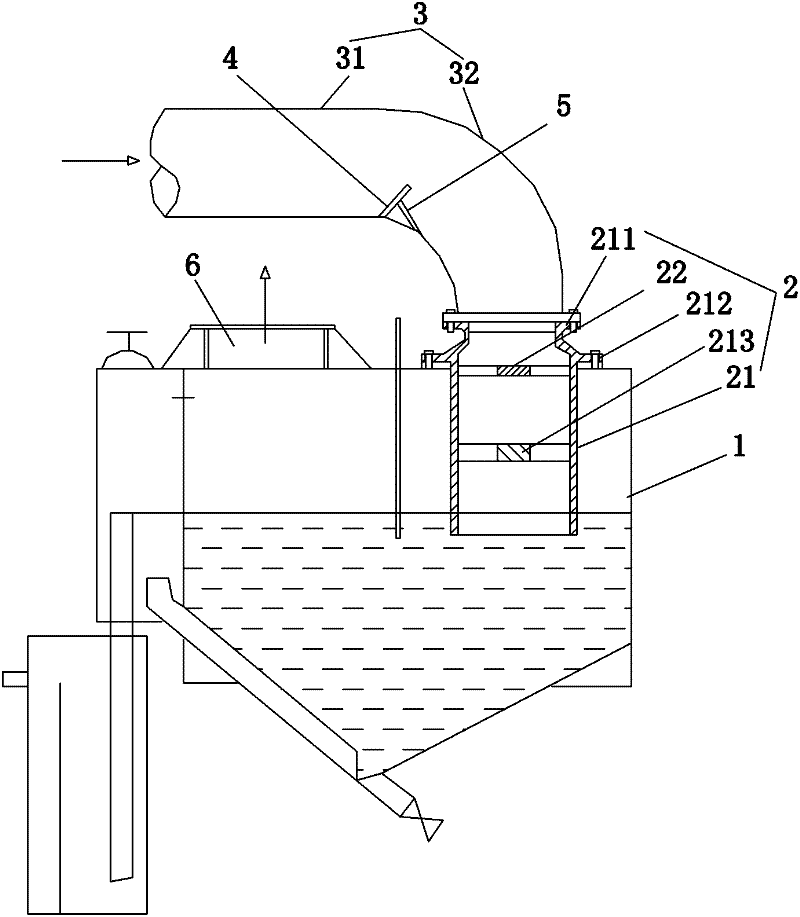

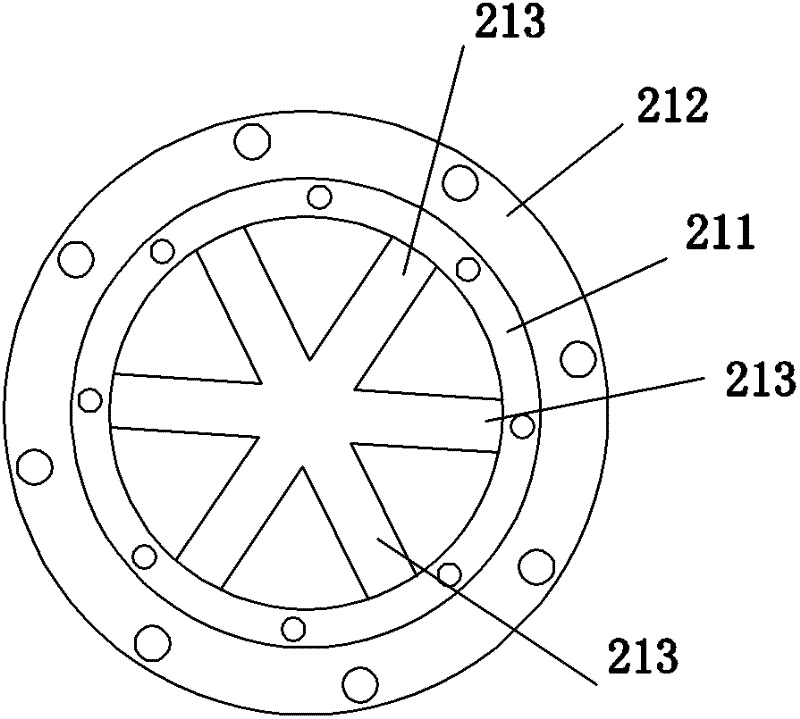

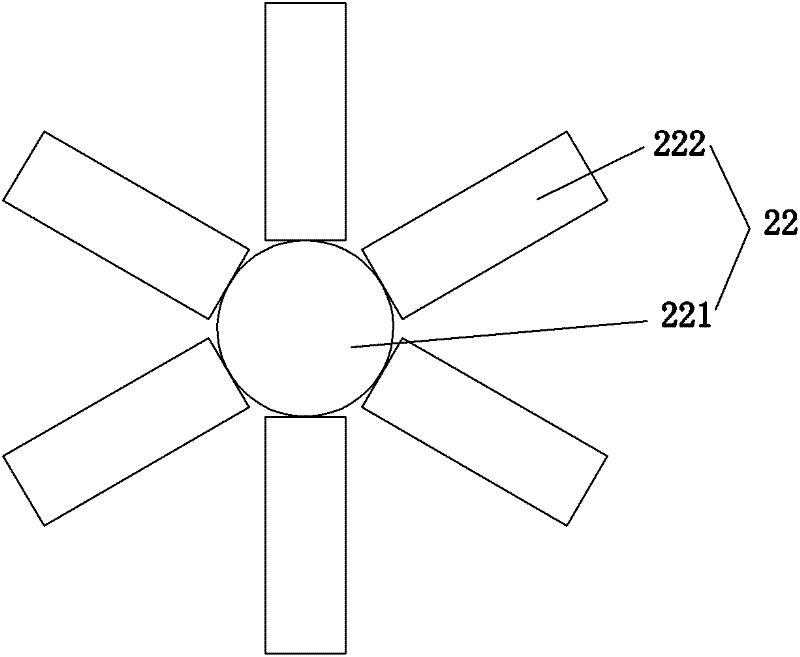

[0013] like figure 1 As shown, the gas scrubber used for the gas generator of the present invention includes a gas scrubber 1, the gas scrubber 1 is a drum-shaped container with a conical lower bottom, and the gas inlet on the gas scrubber 1 is provided with a distributor 2 , the structure of Distributor 2 is as follows figure 2 , 3 As shown, the distributor 2 includes a distributor body 21 and a rib plate 22. The distributor body 21 is a cylinder, and the upper end of the cylinder is provided with a first connecting flange 211 and a second connecting flange 212 at different heights. The inner wall is provided with three partition ribs 213, and the three partition ribs 213 are arranged in a matrix cross section in the cross section of the cylinder, dividing the cylinder cavity into six identical fan-shaped air intake passages; the rib plate 22 includes a circular center plate 221 and six strip plates 222 that are uniformly welded on the periphery of the central plate 221 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com