Stirrer used for molten iron mechanical stirring and efficient mixing desulphurization

A mechanical stirring and agitator technology, which is applied in the field of agitators for high-efficiency mixing and desulfurization of molten iron, can solve the problems of poor dynamic conditions, uneven mixing and dispersion of desulfurizing agents, etc., to ensure the strength of the vortex and the axial downward displacement force , increase the depth of involvement and the mixing and dispersion area, and improve the effect of hydrodynamic conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

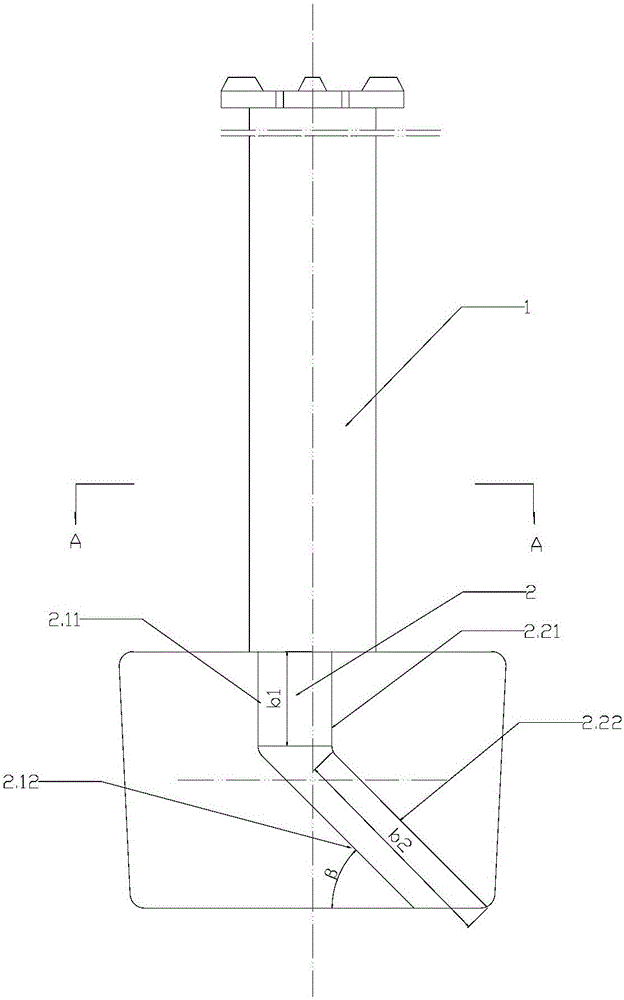

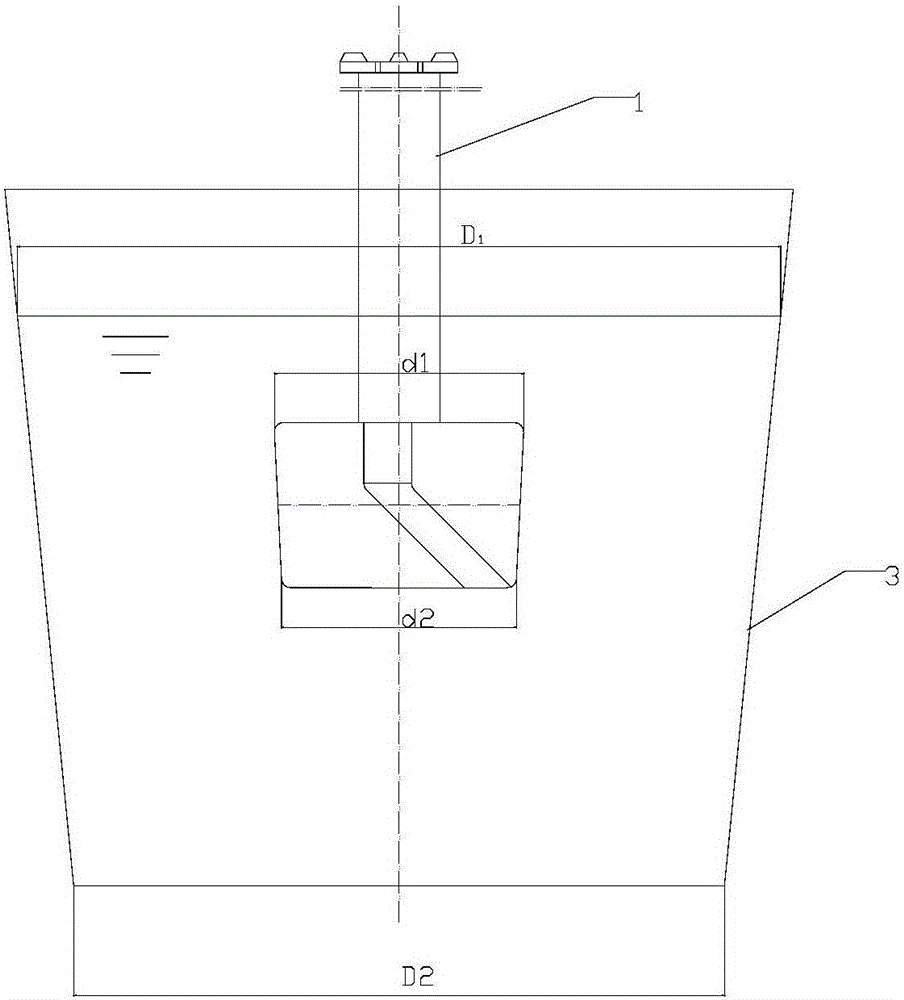

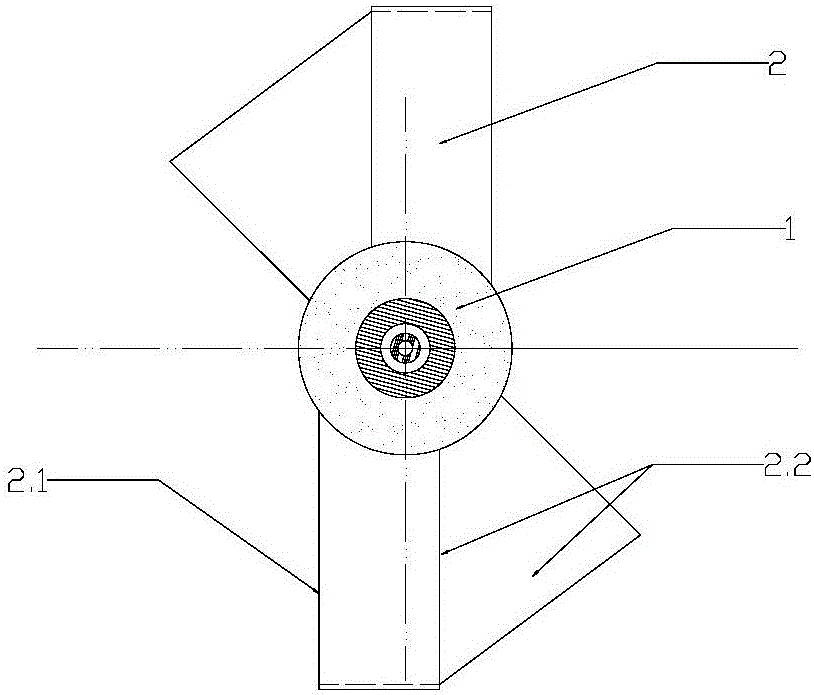

[0027] like Figure 1~3 As shown, a stirrer for mechanically stirring molten iron for efficient mixing and desulfurization, the stirrer is composed of a stirring shaft 1 and a stirring blade 2, the number of stirring blades 2 is 2, and the stirring blade 2 includes a front iron surface 2.1 and a back iron surface 2.2 The iron surface 2.1 is composed of the upper vertical surface section 2.11 of the iron surface and the lower front inclined surface section 2.12 of the iron surface, and the back iron surface 2.2 is composed of the upper vertical surface section 2.21 of the back iron surface and the lower front slope of the back iron surface Composed of surface section 2.22, the width b1 of the upper vertical surface section 2.11 of the iron facing surface and the upper vertical surface section 2.21 of the back iron surface are both 0.25 to 0.35 times the diameter d of the impeller of the agitator, and the lower front inclined surface section 2.12 of the iron facing surface The w...

Embodiment 2

[0032] like figure 1 , 2 Shown in and 4: the agitator structure of the present embodiment and embodiment 1 is basically the same, the difference is:

[0033] The number of stirring blades 2 is three.

Embodiment 3

[0035] The stirrer structure of present embodiment and embodiment 1 is basically the same, and difference is:

[0036] like figure 1 , 2 Shown in and 5: the number of stirring blades 2 is 4 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com