Erosive wear resistant pipeline elbow

A pipeline elbow, erosion-resistant technology, used in elbows, pipeline protection, pipes/pipe joints/fittings, etc., can solve the problems of severe elbow wear, short elbow service life, and high sand content, to ensure Service life, prolong service life, reduce impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

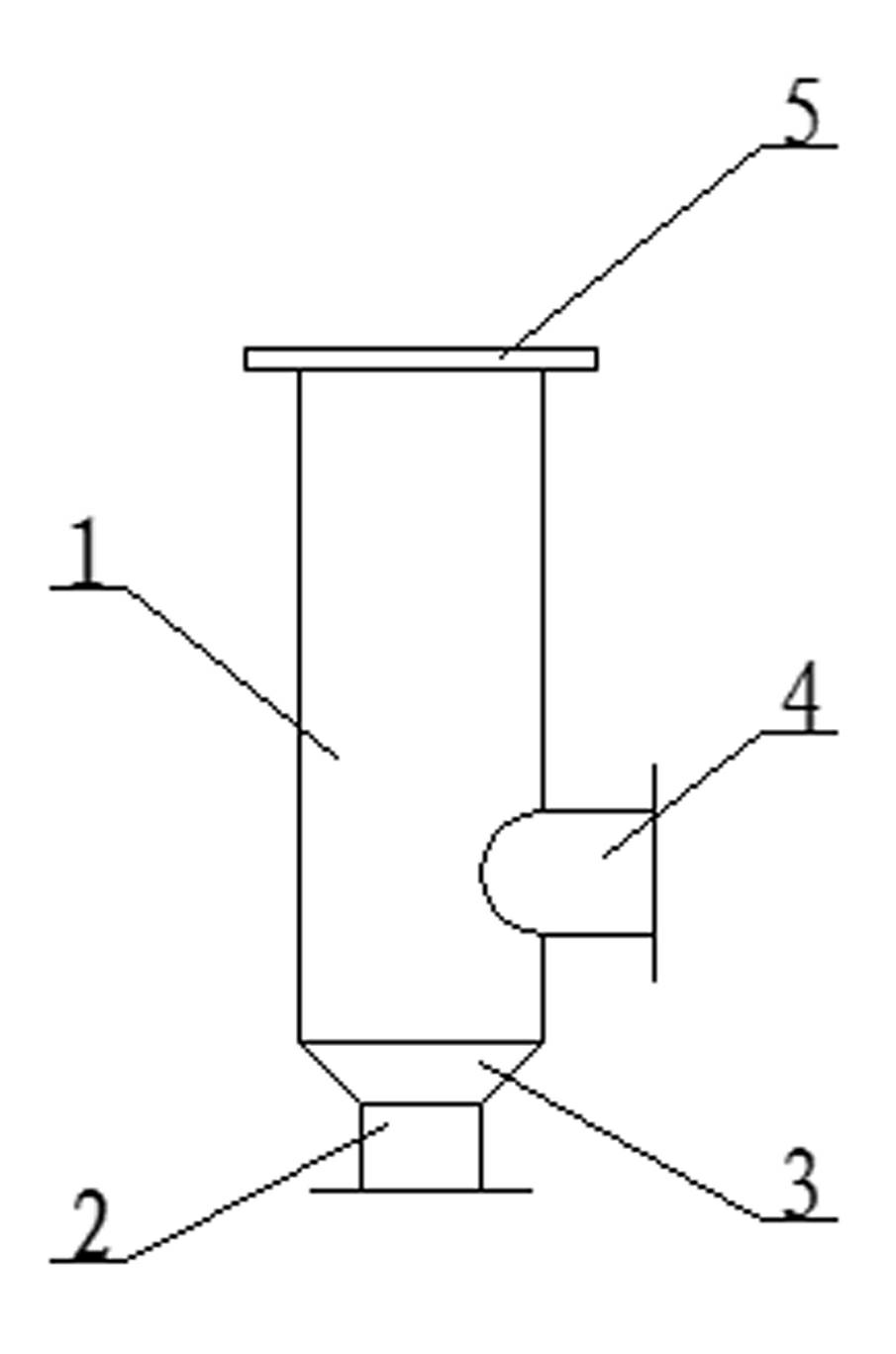

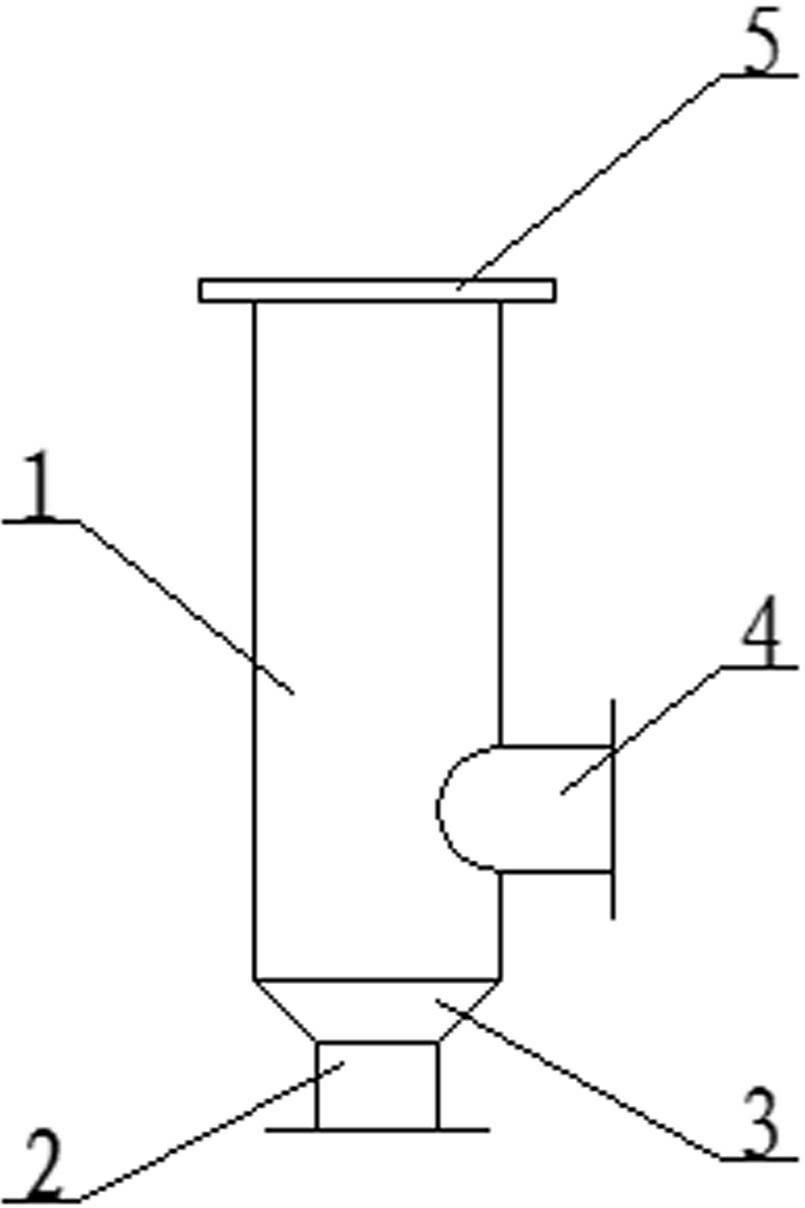

[0013] figure 1 As shown, a pipe elbow resistant to erosion and wear includes a pipe body 1 , a feed pipe 2 , a concentric reducer 3 , a discharge pipe 4 and a blind plate 5 . One end of the pipe body 1 is connected to the feed pipe 2 through the concentric reducer 3, the diameter of the feed pipe 2 is smaller than that of the pipe body 1, and the pipe body 1, the feed pipe 2 and the concentric reducer 3 are concentric; the side of the pipe body 1 The discharge pipe 4 is vertically connected to the wall, the discharge pipe 4 is close to one end of the pipe body 1, and the other end of the pipe body 1 is provided with a blind plate 5; the diameter of the feed pipe 2 is less than or equal to the diameter of the discharge pipe 4; the discharge pipe 4 is connected to the pipe body The distance at one end of 1 is equal to the diameter of feed pipe 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com