Falling-film evaporator balance device

A technology of falling film evaporator and balance device, which is applied in the direction of evaporator accessories, evaporation, chemical instruments and methods, etc., and can solve the problem of increased pressure difference between the upper head and the vapor-liquid separation chamber, increased pressure of the upper head, and heating Eliminate the problems of pipe erosion and wear, achieve the effect of scientific and reasonable structure composition, reduce erosion and wear, and unique measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Now in conjunction with accompanying drawing, the present invention is described in detail:

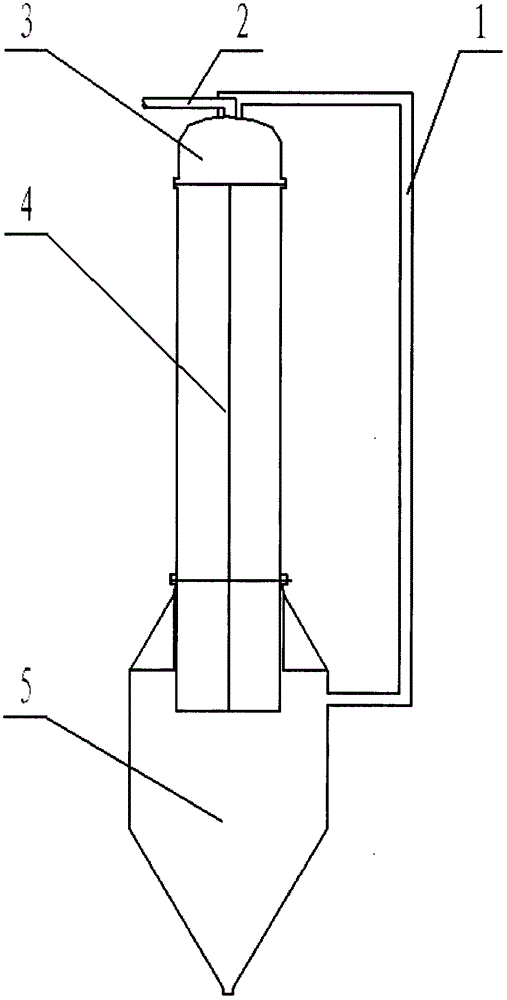

[0015] figure 1 Shown is the structural representation of the present invention. The present invention is composed of a pressure balance pipe (1), a pipeline (2), an upper head (3), a heating pipe (4), and a vapor-liquid separation chamber (5), wherein the lower end of the heating pipe (4) is placed on the steam In the liquid separation chamber (5), the upper head (3) is placed on the heating tube (4), and a pressure balance pipe (1) is connected between the upper head (3) and the vapor-liquid separation chamber (5), Pipeline (2) is installed on the upper head (3).

[0016] Working principle of the present invention:

[0017] In the present invention, a pressure balance pipe (1) is arranged between the upper head (3) and the vapor-liquid separation chamber (5) of the falling film evaporator, and the steam evaporated from the material entering the upper head (3) at a saturate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com