Anti-abrasion device for high-temperature reheater

A reheater and anti-wear technology, which is applied in the direction of steam superheating, lighting and heating equipment, steam boiler accessories, etc., can solve the problems of increased maintenance workload, unsatisfactory effect, large anti-wear blind area, etc. Reduce flue gas wear and soot blowing steam blowing damage, avoid blind spots and easy falling off, and reduce maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

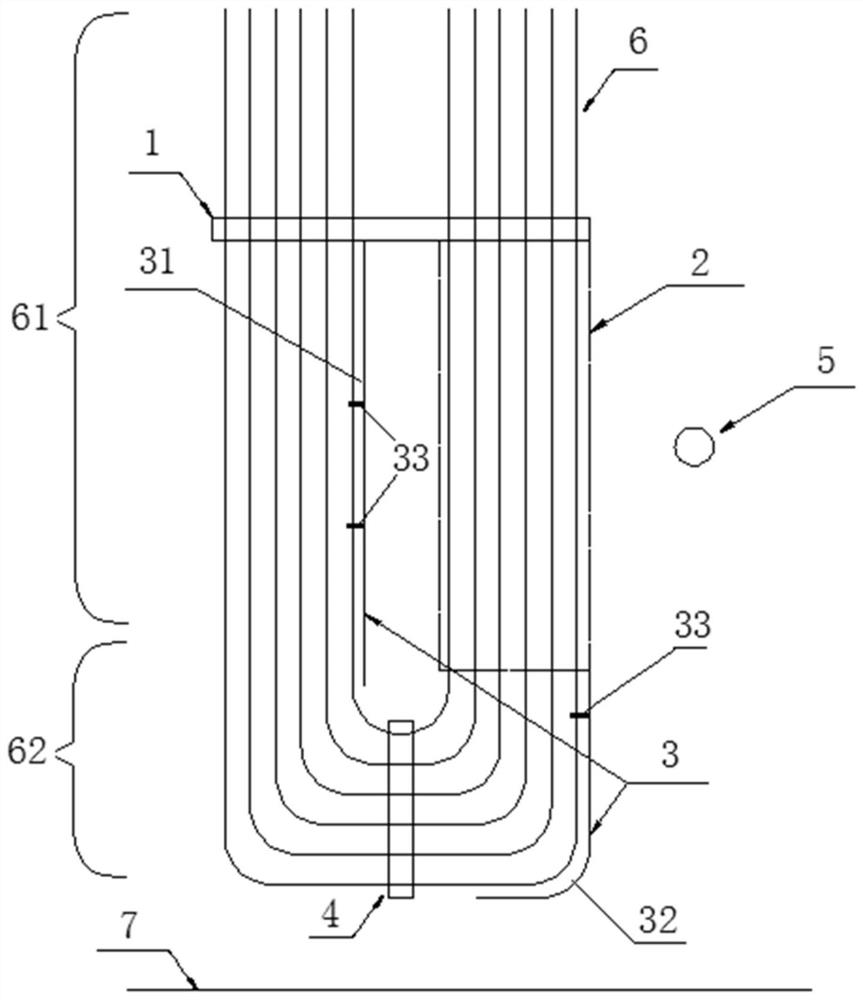

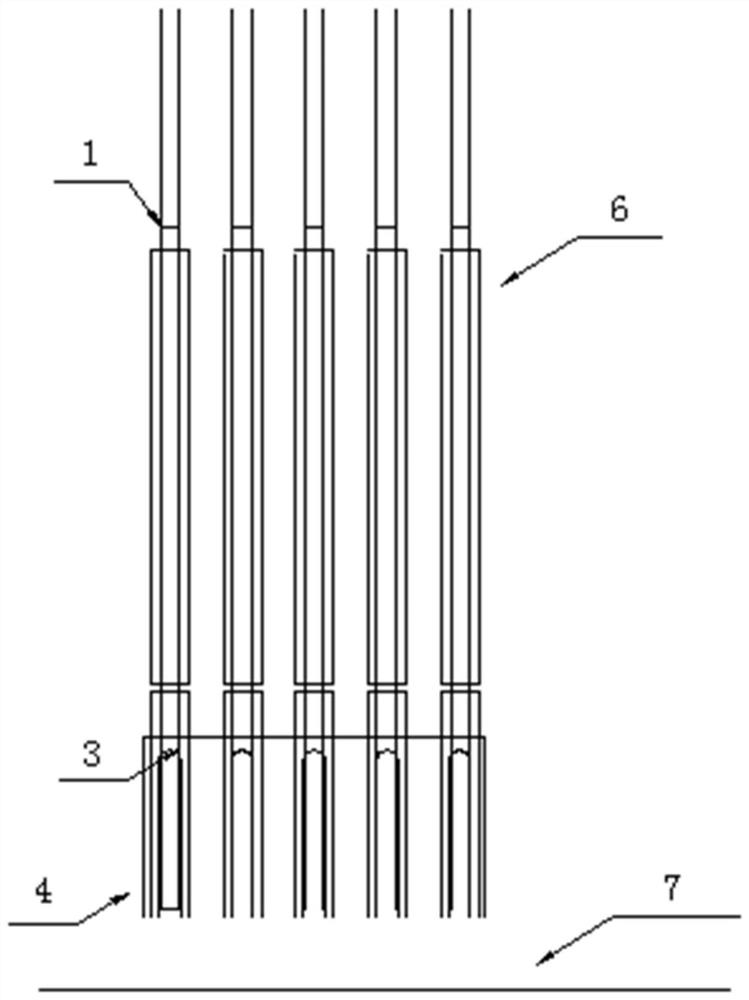

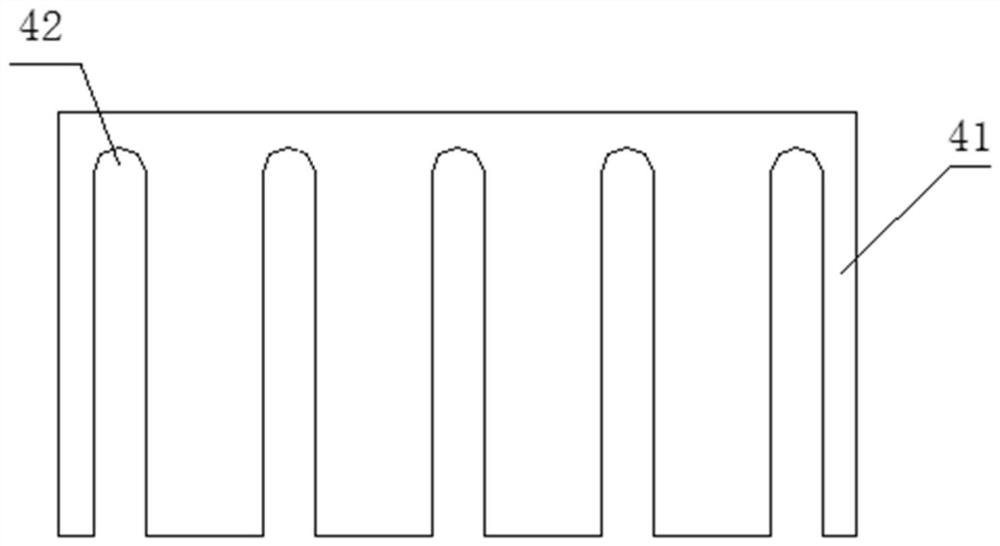

[0030] The invention relates to an anti-wear device for a high-temperature reheater, which is installed on a metal pipe 6 on the heating surface of the high-temperature reheater, and a soot blower 5 is arranged near the high-temperature reheater. The metal tube 6 includes a plurality of furnace tubes arranged side by side at equal intervals. The metal pipe 6 is arranged above the horizontal flue 7 . Such as Figure 1 ~ Figure 2 As shown, the device includes a hole-shaped pipe clamp 1 , an anti-wear box 2 , an anti-wear cover 3 and a comb plate 4 . Each single furnace tube of the metal tube 6 on the heating surface of the high temperature reheater includes a U-shaped bend pipe section 62 and a vertical pipe section 61 above the U-shaped bend pipe section 62 . The soot blower 5 is arranged near the vertical pipe section 61 on the side above the U-shaped elbow pipe section 62 . The hole-type pipe clamp 1 is sheathed and clamped on the vertical pipe section 61 of the metal pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com