Pressure reducing valve and use thereof as well as fluid conveying system

A technology of fluid conveying system and pressure reducing valve, which is applied in the direction of conveyors, conveying bulk materials, balance valves, etc. It can solve the problems of uncomfortable pressure reduction adjustment, easy wear and blockage of flow channels, etc., and achieves the effect of easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

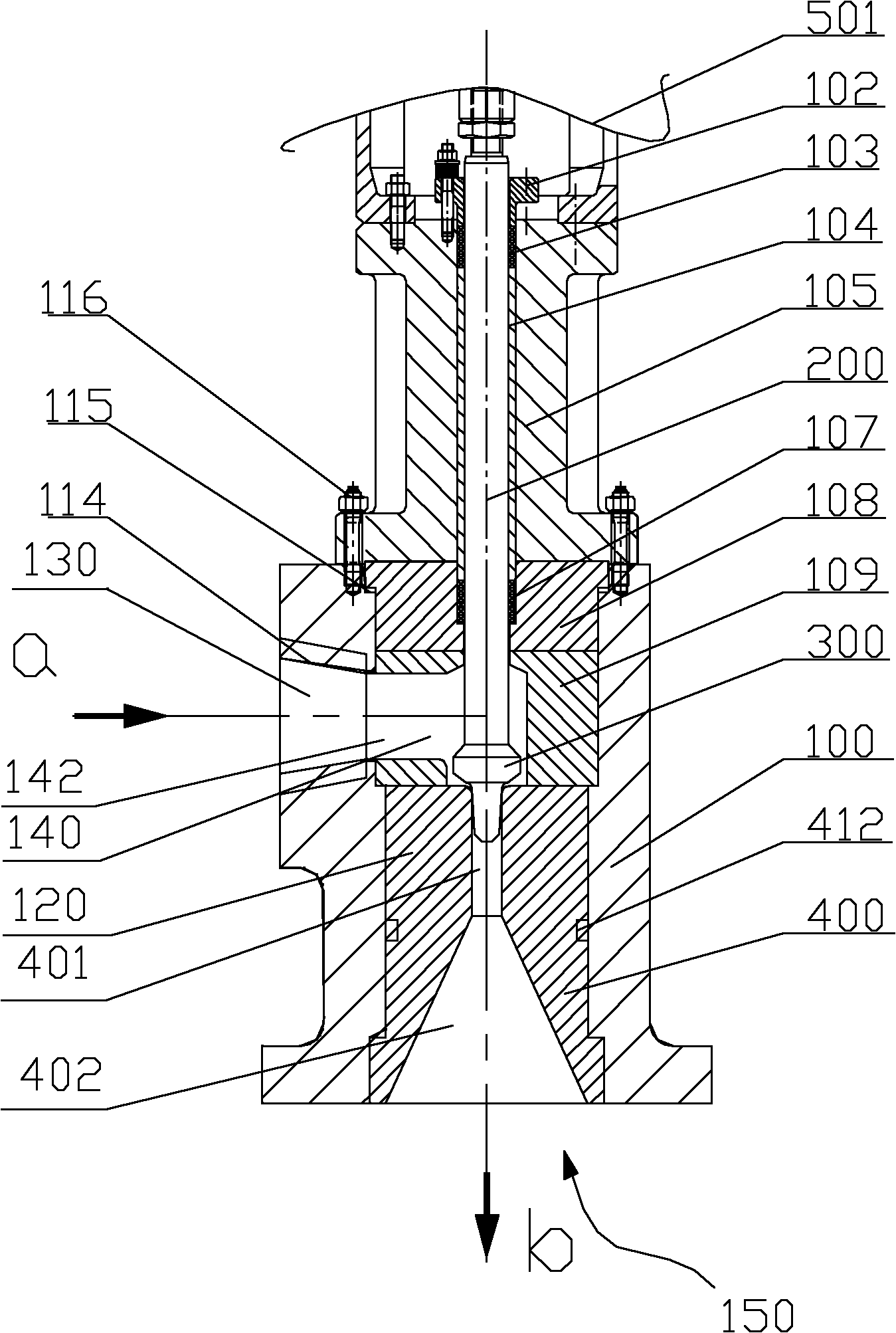

[0116] In the direct coal liquefaction process, the coal slurry reacted in the reactor is transported to the high-temperature and high-pressure separator, the medium temperature is 450°C, and the pressure is 19MPa. Its pressure is reduced to 3MPa through a pressure reducing valve and enters a medium-temperature and medium-pressure separator. The flow rate of coal slurry is 360L / h, and the system requires the liquid level of the high temperature and high pressure separator to be kept stable.

[0117] The valve stem drives the valve core connected with it to move up and down, and the opening of the valve core is controlled at 25%-40%, and the gap between the valve core and the valve seat is adjusted, that is, the flow rate of the coal slurry is adjusted to 300-400L / h , to ensure a relatively stable liquid level in the high-temperature and high-pressure separator, and at the same time realize decompression to reduce the pressure to 3MPa.

Embodiment 2

[0119] In the direct coal liquefaction process, the coal slurry reacted in the reactor is transported to the high-temperature and high-pressure separator, the medium temperature is 450°C, and the pressure is 19MPa. Its pressure is reduced to 1MPa through the pressure reducing valve and enters the storage tank. The flow rate of coal slurry is 400L / h, and the system requires the liquid level of the high temperature and high pressure separator to be kept stable.

[0120] The valve stem drives the valve core connected with it to move up and down, and the opening of the valve core is controlled at 25%-30%, and the gap between the valve core and the valve seat is adjusted, that is, the flow rate of the coal slurry is adjusted to 380-420L / h , to ensure a relatively stable liquid level in the high-temperature and high-pressure separator, and at the same time realize decompression to reduce the pressure to 1MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com