High-temperature and high-pressure erosion-corrosion fatigue testing device

A high-temperature, high-pressure, corrosion-fatigue technology, applied to measuring devices, using stable bending force to test the strength of materials, instruments, etc., can solve problems such as pipe string failure, and achieve the effect of good sealing performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

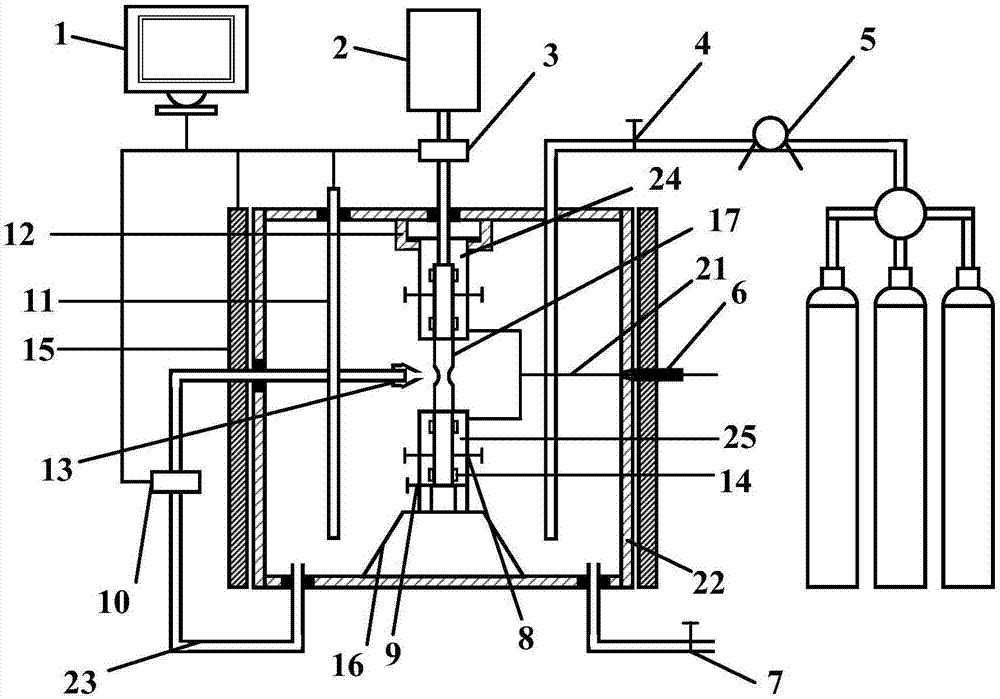

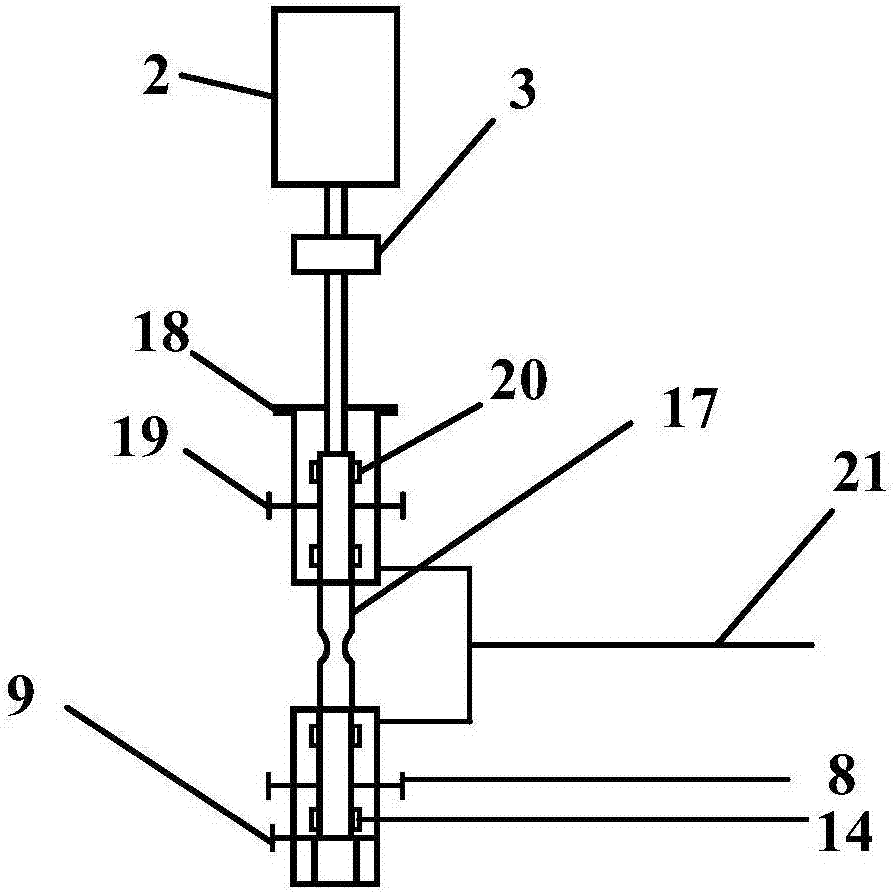

[0023] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment

[0024] Such as figure 1 with figure 2 As shown, the high temperature and high pressure erosion corrosion fatigue test device includes a high temperature autoclave 22, and a sample clamping mechanism is installed in the high temperature autoclave 22; A sealed erosion circulation loop 23, an erosion pump 10 is connected to the sealed erosion circulation loop 23, the water outlet of the erosion pump 10 is connected to a nozzle 13, and the nozzle 13 corresponds to the sample 17 in the sample holding mechanism, and the erosion pump 10 is used to 10 Make the fluid in the high-temperature autoclave body 22 form a high-speed erosion and corrosion environment on the sample 17; there is a temperature and pressure sensor 11 in the high-temperature and autoclave body 22, and the erosion pump 10 and the temperature and pressure sensor 11 are respectively connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com