Advanced erosion-corrosion resistant boride cermets

A kind of cermet, boride technology, applied in the field of cermet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 70 vol% of 14.0 μm average diameter TiB2 powder (99.5% purity, obtained from Alfa Aesar, 99% sieved below -325 mesh) and 30 vol% of 6.7 μm average diameter 304SS powder (Osprey Metals, 95.9% sieved below -16 μm) was dispersed with ethanol in a low-pressure polyethylene milling vessel. The powder in ethanol was mixed with yttria-toughened zirconia pellets (10 mm diameter, obtained from Tosoh Ceramics) in a ball mill at 100 rpm for 24 hours. Ethanol was removed from the mixed powder by heating at 130° C. in a vacuum oven for 24 hours. The dry powder was compacted in a 40 mm diameter die in a hydraulic coaxial press (SPEX 3630 Automated X-press) at a pressure of 5,000 psi. The resulting green disc was ramped at 25°C / min to 400°C under argon and held for 30 minutes to remove residual solvent. The wafer was then heated to 1500°C at 15°C / min in argon and held at 1500°C for 2 hours. Then the temperature was reduced to below 100°C at -15°C / min.

[0052] The resulting cermet...

Embodiment 2

[0056] As described in Example 1, 75 vol% TiB with an average diameter of 14.0 μm 2 Powder (99.5% pure, obtained from Alfa Aesar, 99% screened below -325 mesh) and 25 vol% of 304SS powder (Osprey metal, 95.9 screened below -16 μm) with an average diameter of 6.7 μm) were used to process the metal Ceramic discs. The wafer was then heated to 1700°C at 15°C / min in argon and held at 1700°C for 30 min hrs. Then the temperature was reduced to below 100°C at -15°C / min.

[0057] The resulting cermet contains:

[0058] i) 74 vol% of TiB with an average particle size of 7 μm 2 ,

[0059] ii) 3 vol% of the second boride M with an average particle size of 2 μm 2 B

[0060] iii) 23 vol% Cr-poor alloy binder.

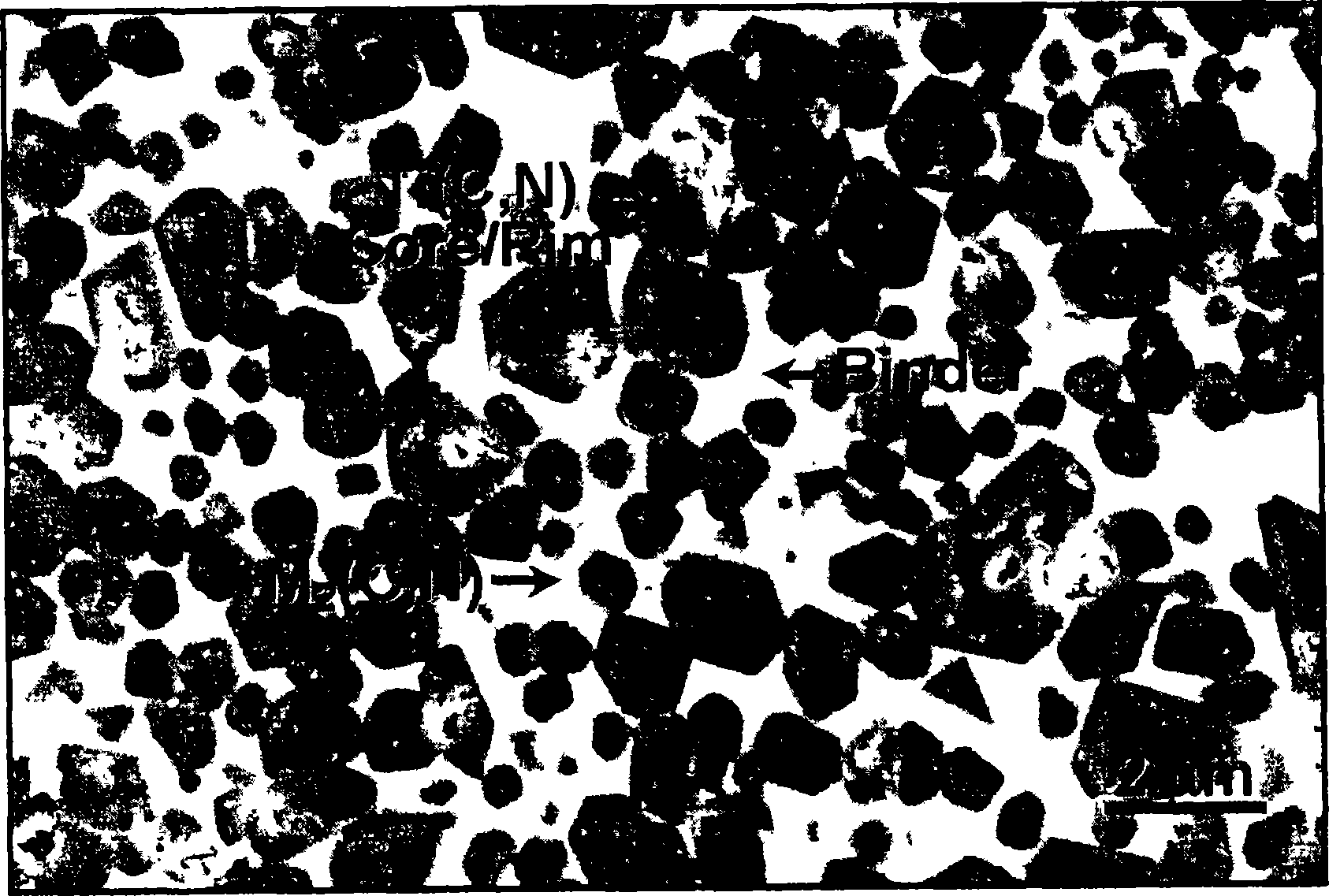

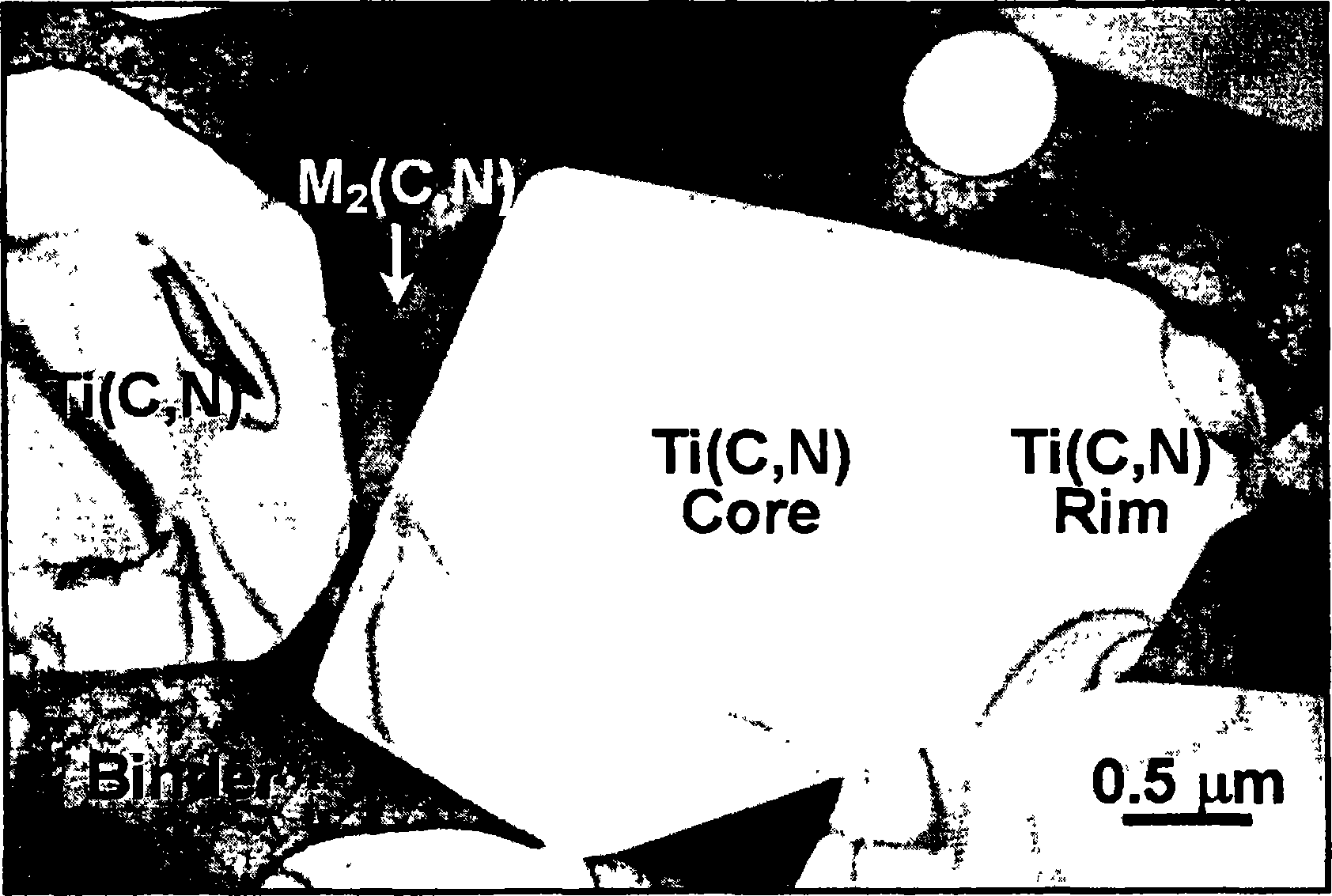

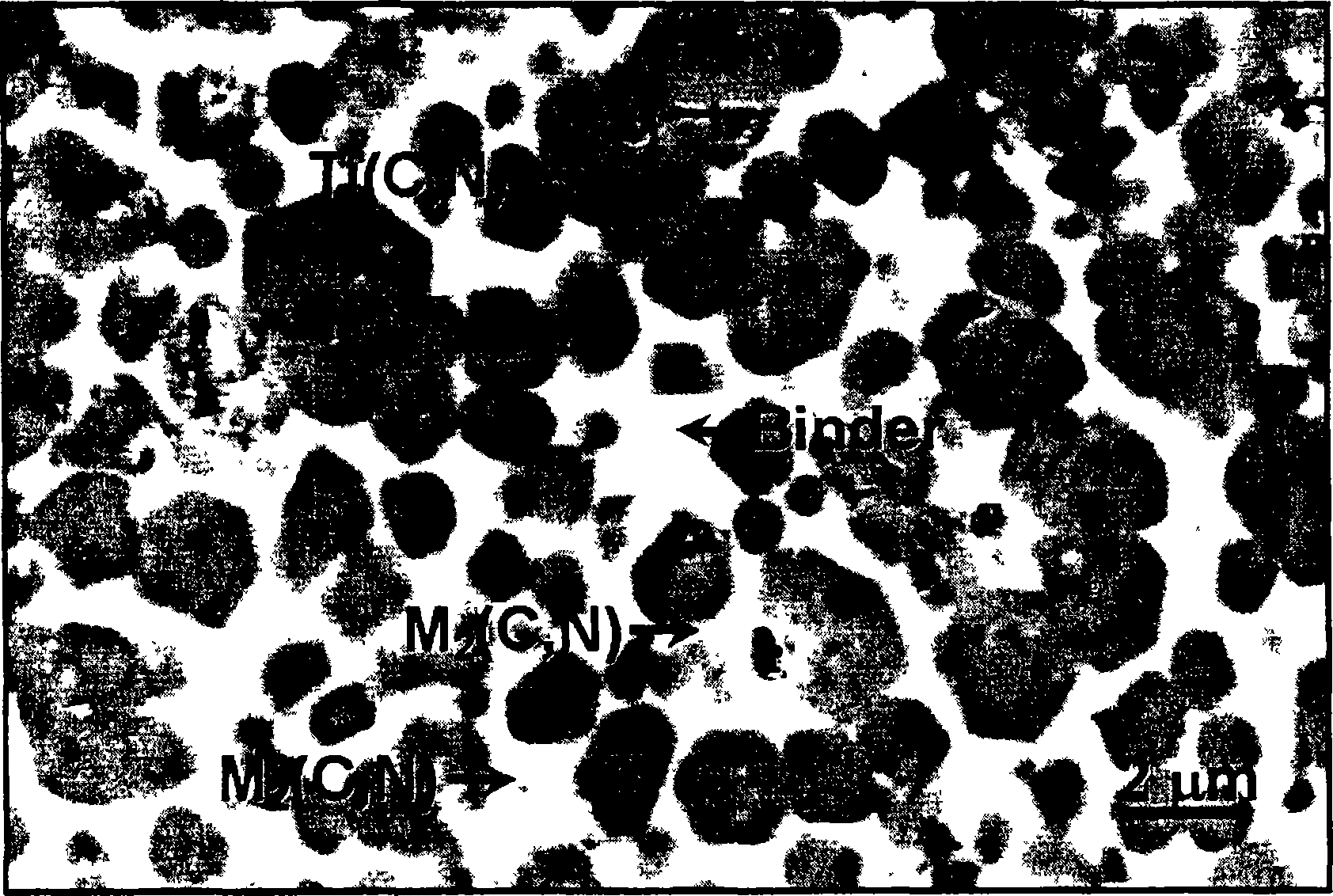

[0061] figure 2 is TiB processed according to this example 2 SEM images of cermets, where the scale bar represents 10um. In this image, TiB 2 The phase appeared to be dark in color and the binder phase appeared to be light in color. Cr-rich M 2 A second boride phase of ...

Embodiment 3

[0063] As described in Example 1, 70vol% of TiB with an average diameter of 14.0um 2 Powder (99.5% purity, obtained from Alfa Aesar, 99% screened below -325 mesh) and 30 vol% of 6.7 μm average diameter 304SS powder (Osprey metal, 95.9% screened below -16 μm) were used to process the metal ceramics. The cermet disc was then heated to 1500°C in argon and held for 2 hours. Then the temperature was reduced to below 100°C at -15°C / min. Hot isostatic pressing of pre-sintered discs in argon at 12°C / min to 1600°C and 30 kpsi (206MPa) and hold at 1600°C and 30kpsi (206MPa) for 1 hour . It was then cooled down to 1200°C at 5°C / min and held at 1200°C for 4 hours. Then the temperature is reduced to below 100°C at -30°C / min.

[0064] The resulting cermet contains:

[0065] i) 69 vol% of TiB with an average particle size of 7 μm 2 ,

[0066] ii) 4 vol% of the second boride M with an average particle size of 2 μm 2 B, wherein M=55Cr: 42Fe: 3Ti (wt%],

[0067] iii) 27vol% Cr-poor al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com