Rotary test device for simulating erosion corrosion on inner wall of pipeline

A technology of erosion corrosion and experimental equipment, which is applied in the direction of measuring equipment, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of high construction cost of pipe flow erosion corrosion experimental equipment, and achieve real-time electrochemical parameter measurement and realization The effect of weightlessness measurement and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

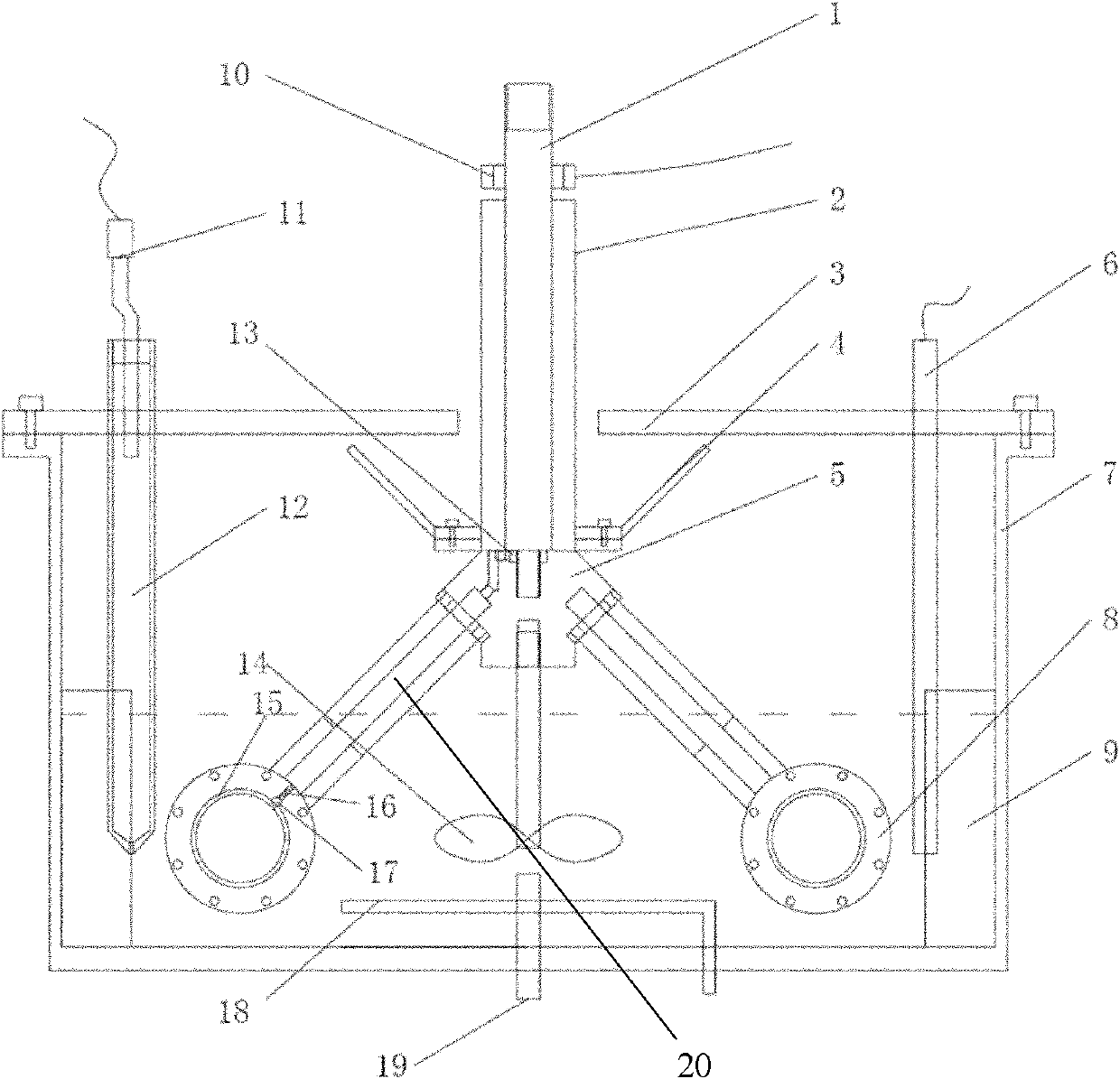

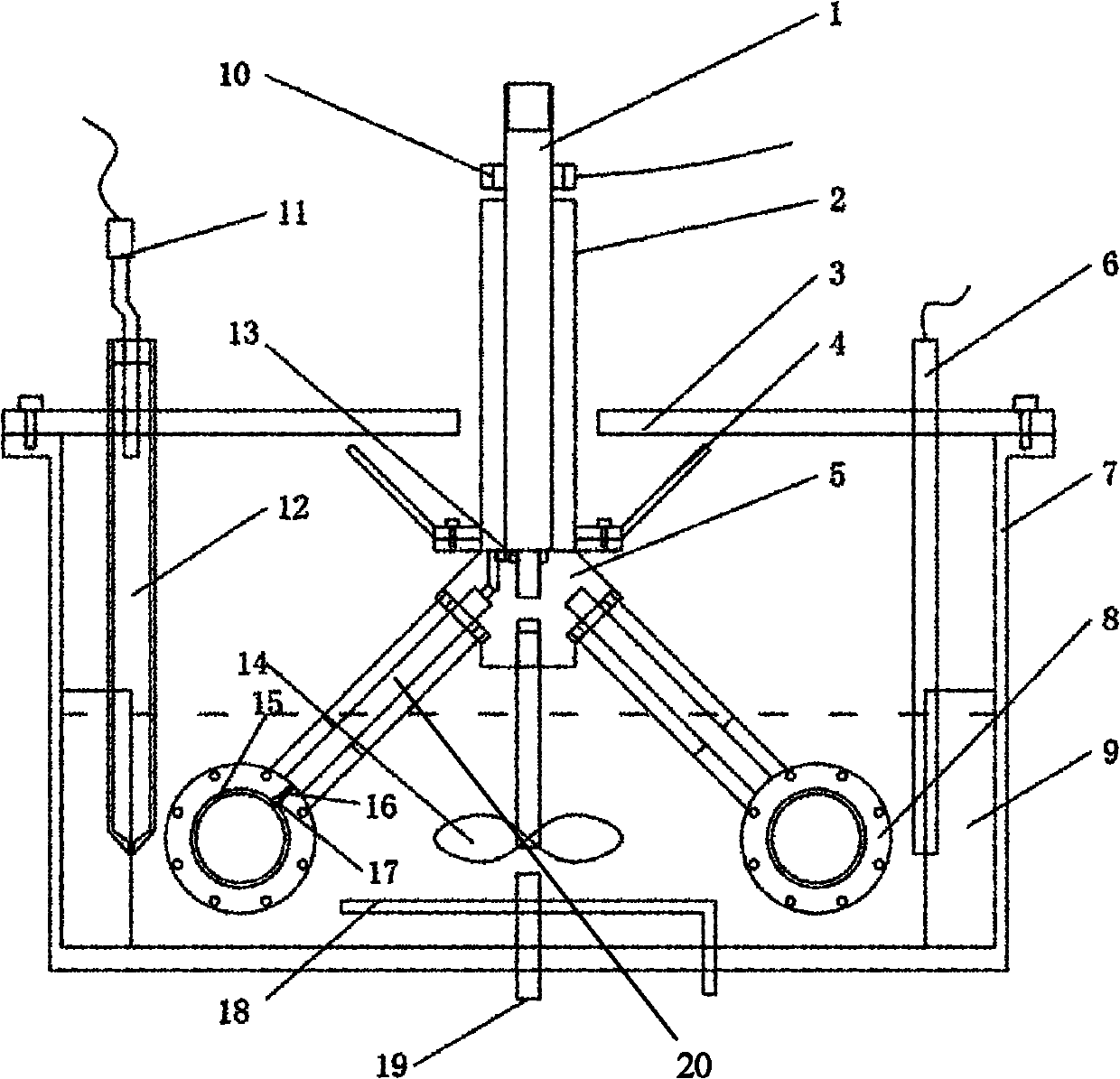

[0024] like figure 1 As shown, the rotary experimental device for simulating pipeline inner wall erosion corrosion in the present invention has a motor, a slurry tank, and electrochemical testing equipment, and adopts a motor equipped with a frequency converter to drive the rotating shaft 1 as power to further drive the sample holder 8 and the ring Sample 15 was rotated in the slurry in the slurry tank, and the data was tested by the electrochemical testing system. The device mainly includes: rotating shaft 1, polytetrafluoroethylene sleeve 2, slurry tank cover 3, splash guard 4, adapter 5, auxiliary electrode 6, slurry tank 7, sample fixture 8, baffle 9, Carbon brush 10, calomel electrode 11, salt bridge 12, copper nut 13, stirring impeller 14, ring sample 15, spring 16, copper ball 17, heater 18, thermocouple 19, stainless steel rod 20, etc. The specific structure is as follows:

[0025] The top of the slurry tank 7 is connected to the upper cover 3 of the slurry tank by bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com