Method and apparatus for testing high temperature fluid erosion corrosion resistance of material

A technology of erosion corrosion and high temperature resistance, applied in the experimental field, can solve the problems of incomplete consideration of experimental means, insufficient practical application guiding significance, poor repeatability, etc., and achieve the effect of strong practical application guiding significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

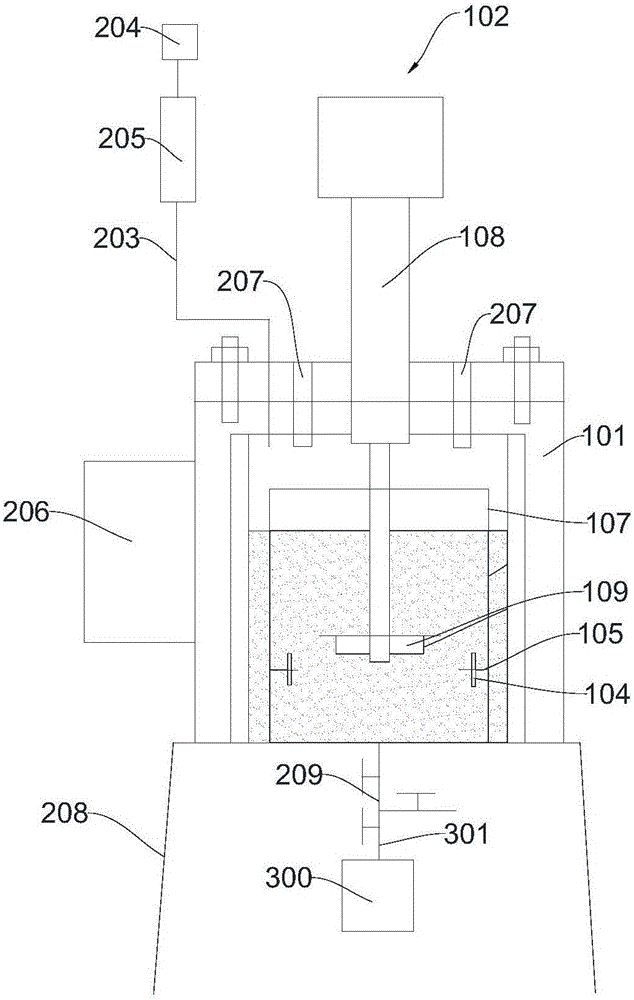

[0073] Embodiment 2, with reference to figure 1 .

[0074] A method for testing material 104 resistance to high temperature fluid erosion corrosion performance, comprising the following steps:

[0075] Select at least one test material 104, the test material 104 is a metal material;

[0076] Clean the surface of the metal material and dry it, weigh the metal material and record the mass m before the experiment, measure the surface area of the metal material and record the surface area S;

[0077] Select the simulated experimental fluid medium and add it into the box 101, and the box 101 is provided with a stirring drive 102;

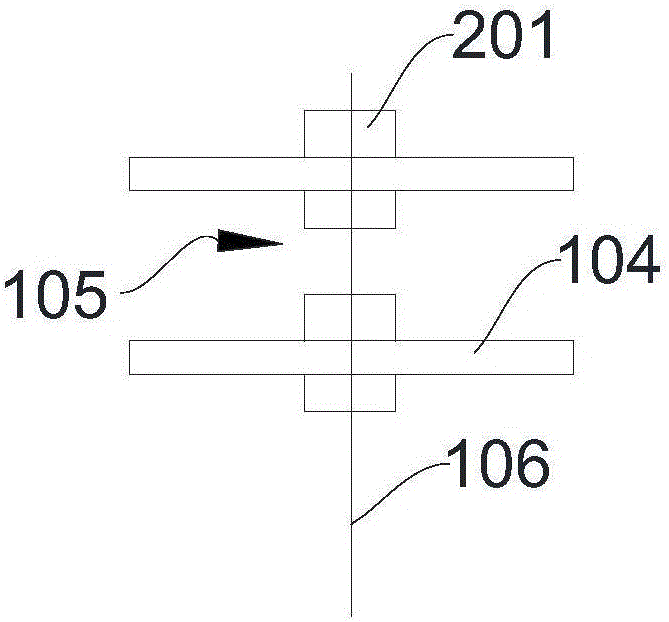

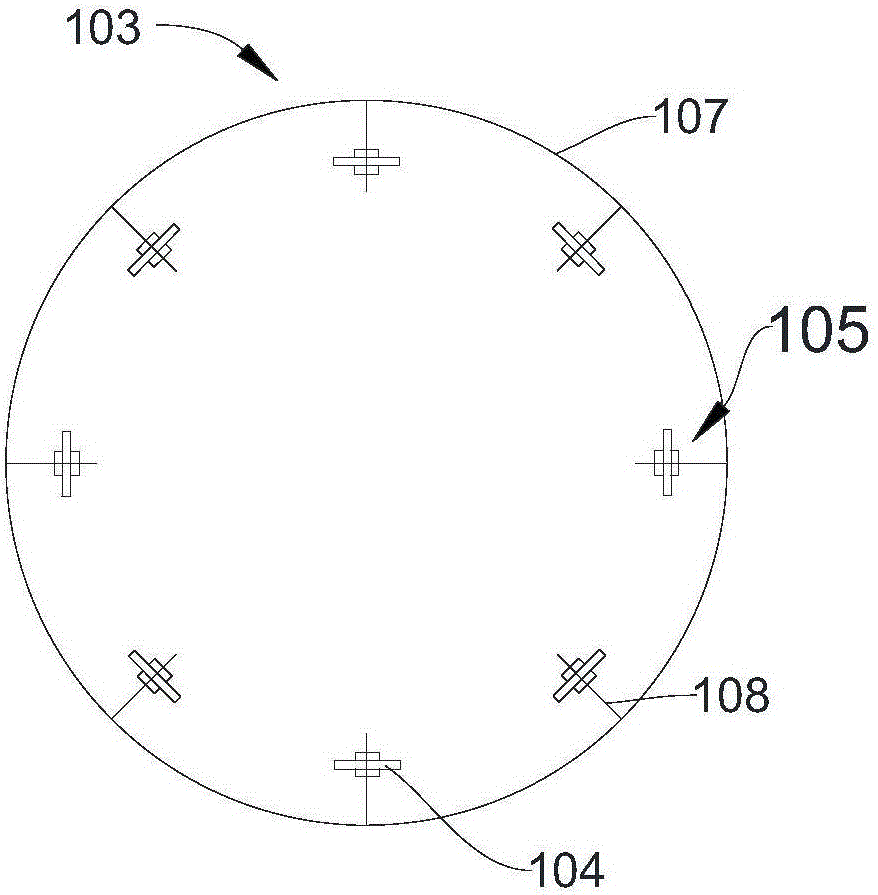

[0078] Install the metal material on the material mounting frame 103 according to the simulated angle, and then place the material mounting frame 103 in the experimental fluid medium of the box 101;

[0079] Adjust the temperature of the experimental fluid medium to the simulated ambient temperature and keep the temperature constant;

[0080] Adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com