Injection type erosion corrosion testing device

A technology for scouring corrosion and testing devices, which is used in measurement devices, weather resistance/light resistance/corrosion resistance, and wear resistance testing. The effect of controllable experimental environmental factors and real-time accurate electrochemical testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

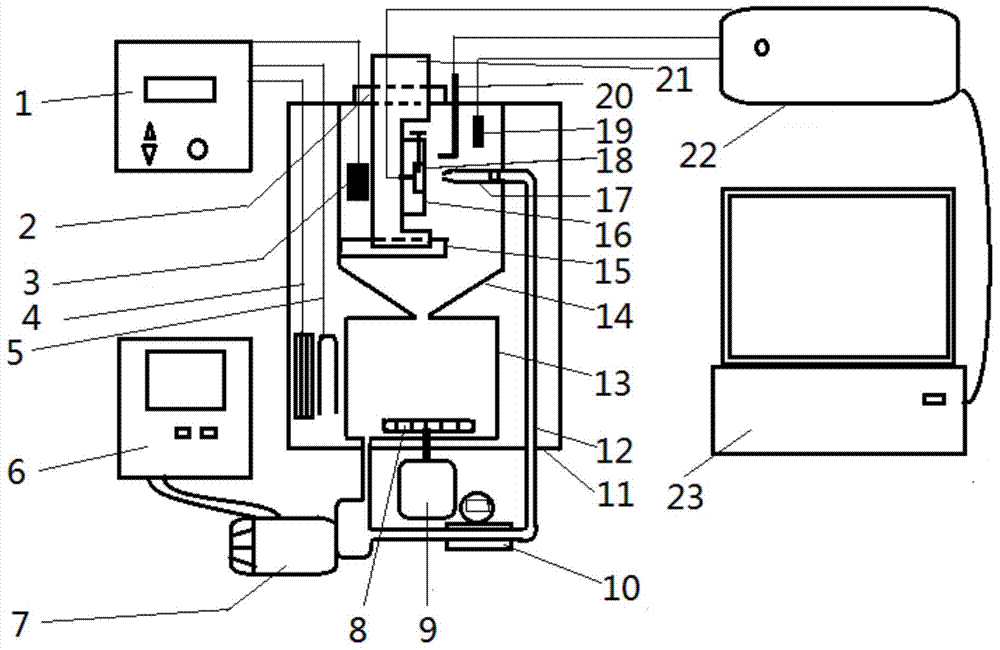

[0019] exist figure 1 Among them, a temperature control panel 1, a temperature detector 3, a refrigerator 4, and a thermocouple 5 form a temperature control system. The temperature detector 3 is placed in the flushing chamber 14 , and the refrigerator 4 and the thermocouple 5 are placed in the constant temperature liquid storage tank 11 outside the flushing chamber 14 . The lower end of the flushing chamber is connected to the stirring chamber 13, and the lower end of the stirring chamber 13 is connected to the circulating pump 7, and the circulating pump 7 is connected to the polytetrafluoroethylene plastic nozzle 17 in the flushing chamber 14 through the polytetrafluoroethylene pipe 12 to form a fluid circulation circuit . The circulating pump 7 is connected in series with the frequency converter 6 and connected to the power supply. An electromagnetic flowmeter 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com