High temperature and high pressure gas, liquid and solid phase erosion corrosion test device and method

A corrosion test, high temperature and high pressure technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as large differences in erosion and corrosion results

Inactive Publication Date: 2019-06-07

CHINA PETROLEUM ENG & CONSTR

View PDF13 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current indoor erosion and corrosion test equipment can only simulate gas-liquid two-phase, gas-solid two-phase or liquid-solid two-phase erosion, and there are very few reports on gas, liquid, and solid three-phase erosion and cor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

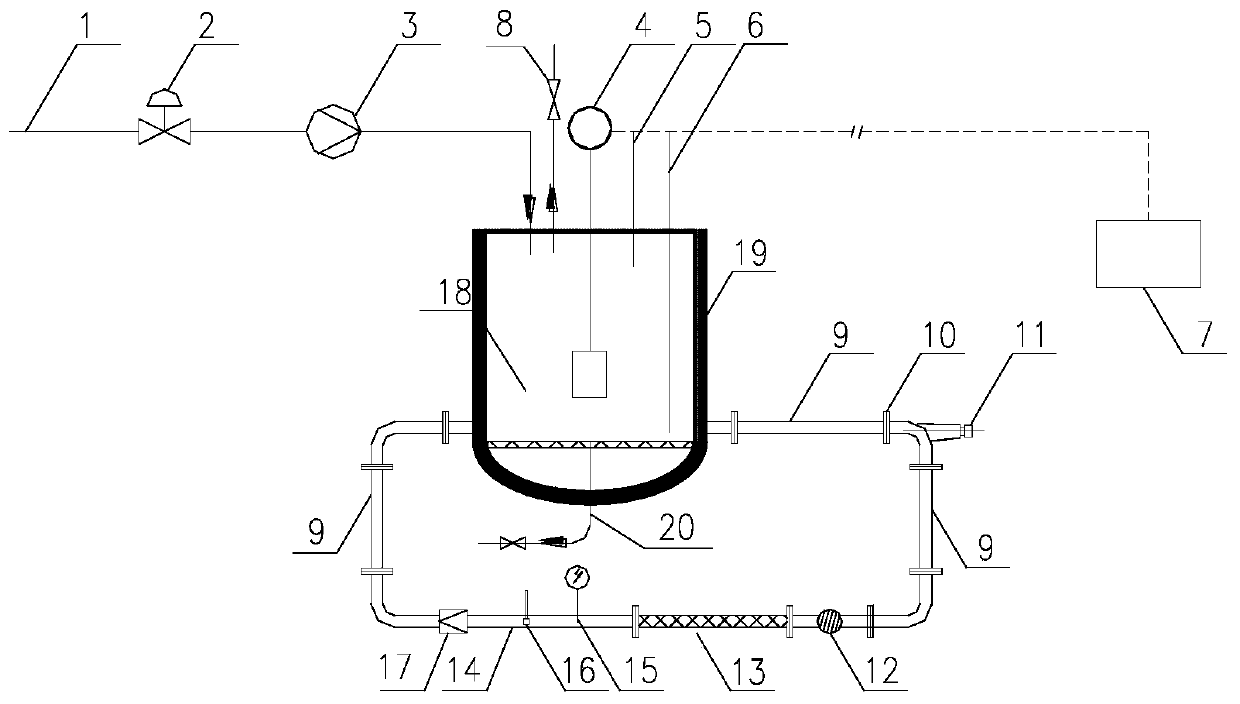

The invention discloses a high temperature and high pressure gas, liquid and solid phase erosion corrosion test device and method. The test device comprises a high temperature and high pressure test box connected to a circulation test loop, the circulation loop is provided with a circulation pump, a cover of the high temperature and high pressure test box is provided with an electromagnetic stirring device, a temperature sensing probe and a pressure sensor, and the electromagnetic stirring device, the temperature sensing probe and the pressure sensor are connected with a control system; the circulation test loop is provided with a corrosion test unit and an electrochemical test unit; and the circulation test loop is provided with a transparent window for observing the flow state of a fluidin the pipe. The beneficial effects are that the device can simulate the on-site working condition environment, simulate the corrosion of a metal material in the pipeline and simulate the gas, liquidand solid phase erosion and corrosion test, carry out electrochemical tests, corrosion inhibitor evaluation, rubber and plastic related corrosion tests and other corrosion tests, and can also carry out whole-pipe on-line corrosion tests on metal materials and non-metal materials.

Description

technical field [0001] The invention belongs to the field of corrosion, and in particular relates to a high-temperature, high-pressure gas, liquid, and solid three-phase erosion corrosion test device and method, which can simulate the erosion and corrosion of pipelines by fluid transported under the environmental conditions of oil and gas fields, and can be used to study gas, liquid, and solid three-phase erosion corrosion test devices and methods. Erosion corrosion and electrochemical corrosion under liquid and solid three-phase fluid flow conditions can be used to test corrosion inhibitor performance, coating performance, corrosion resistance of metal and non-metal materials, etc., can observe fluid flow state, and can conduct material tests and Piping tests are available. Background technique [0002] Erosion corrosion is a metal damage phenomenon caused by relative movement between the metal surface and the corrosive fluid. localized corrosion. Erosion corrosion is a v...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N17/00

Inventor 李林辉崔磊施岱艳姜放李天雷张金钟杜磊

Owner CHINA PETROLEUM ENG & CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com