Biomedical degradable Mg-Zn-Zr-Sc alloy and preparation method thereof

A biomedical and alloy technology, applied in the field of biomaterials, achieves the effects of safety, reliability, excellent performance, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

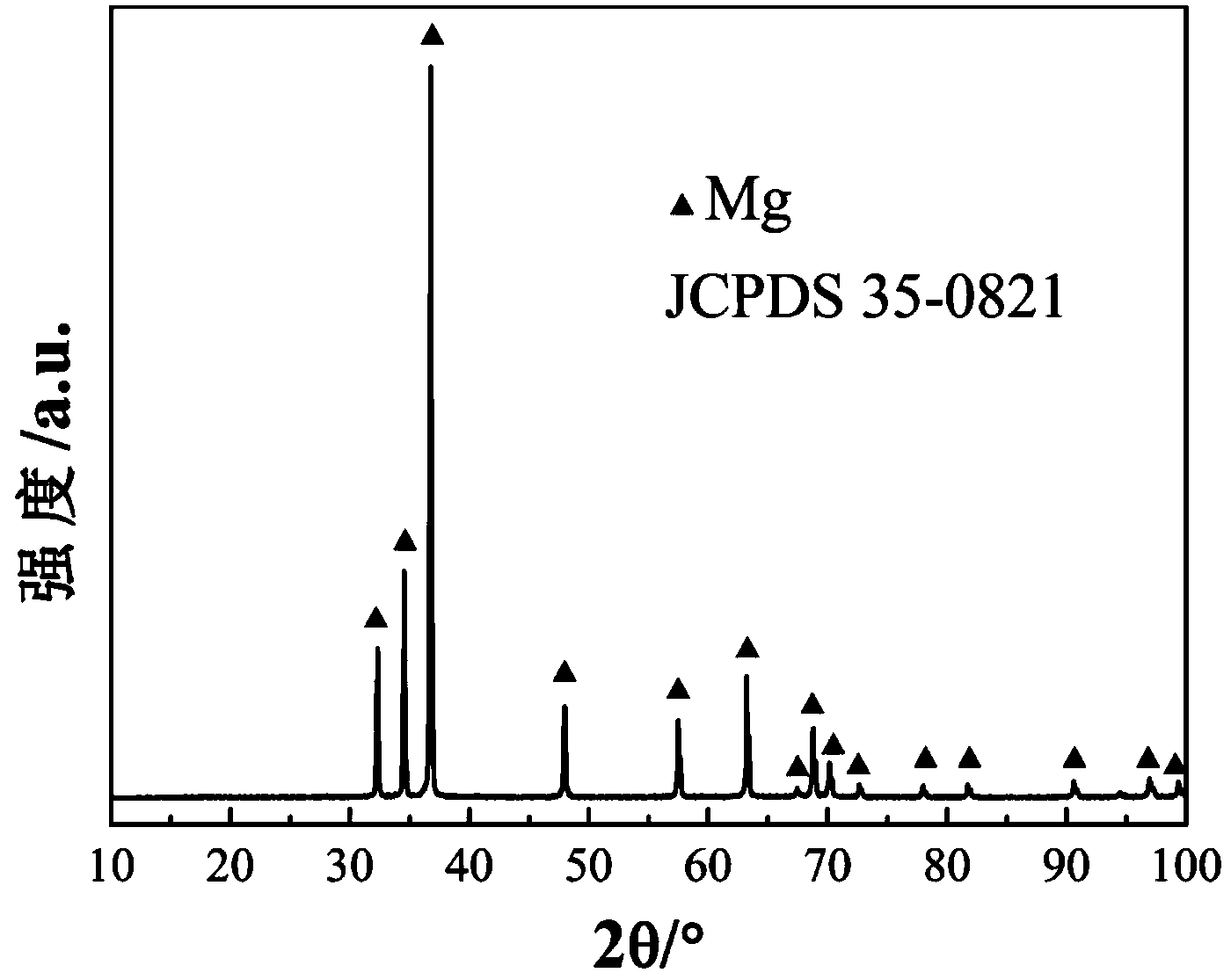

Image

Examples

Embodiment 1

[0027] The raw materials are Mg with purity ≥99.99%, Zn with purity ≥99.995%, Mg-30%Zr master alloy with purity ≥99.8%, and magnesium-scandium master alloy with purity ≥99.8%. The nominal composition is calculated as: Zn1. 5%, Zr0.6%, Sc0.3%, and the rest are alloyed with Mg. First, Mg is heated and melted in a crucible by a resistance furnace. The protective atmosphere used is a mixed gas with a volume percentage of sulfur hexafluoride: carbon dioxide = 1:100. When the melt temperature is 720 ° C, Zn is added to the crucible and the temperature is raised to 750 Then add Mg-30%Zr master alloy at ℃, then raise the temperature to 780℃, add magnesium-scandium master alloy and keep it warm for 30min, then cool down to 740℃, after stirring for 1min and standing for 3min, melt the melt at a volume percentage of 6 Sulfur fluoride: carbon dioxide = 1:100 is cast into a permanent mold with a preheating temperature of 200°C under a protective atmosphere to obtain a magnesium alloy ingot...

Embodiment 2

[0032] The raw materials are Mg with purity ≥99.99%, Zn with purity ≥99.995%, Mg-30%Zr master alloy with purity ≥99.8%, and magnesium-scandium master alloy with purity ≥99.8%. The nominal composition is calculated as: Zn1. 5%, Zr0.6%, Sc0.5%, and the rest are alloyed with Mg. First, Mg is heated and melted in a crucible by a resistance furnace. The protective atmosphere used is a mixed gas with a volume percentage of sulfur hexafluoride: carbon dioxide = 1:100. When the melt temperature is 720 ° C, Zn is added to the crucible and the temperature is raised to 750 Then add Mg-30%Zr master alloy at ℃, then raise the temperature to 780℃, add magnesium-scandium master alloy and keep it warm for 30min, then cool down to 740℃, after stirring for 1min and standing for 3min, melt the melt at a volume percentage of 6 Sulfur fluoride: carbon dioxide = 1:100 is cast into a permanent mold with a preheating temperature of 200°C under a protective atmosphere to obtain a magnesium alloy ingot...

Embodiment 3

[0034] The raw materials are Mg with purity ≥99.99%, Zn with purity ≥99.995%, Mg-30%Zr master alloy with purity ≥99.8%, and magnesium-scandium master alloy with purity ≥99.8%. The nominal composition is calculated as: Zn1. 5%, Zr0.6%, Sc1%, and the rest are alloyed with Mg. First, Mg is heated and melted in a crucible by a resistance furnace. The protective atmosphere used is a mixed gas with a volume percentage of sulfur hexafluoride: carbon dioxide = 1:100. When the melt temperature is 720 ° C, Zn is added to the crucible and the temperature is raised to 750 Then add Mg-30%Zr master alloy at ℃, then raise the temperature to 780℃, add magnesium-scandium master alloy and keep it warm for 30min, then cool down to 740℃, after stirring for 1min and standing for 3min, melt the melt at a volume percentage of 6 Sulfur fluoride: carbon dioxide = 1:100 is cast into a permanent mold with a preheating temperature of 200°C under a protective atmosphere to obtain a magnesium alloy ingot. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com