Multichannel erosion-corrosion test system and method

A technology for scouring corrosion and testing systems, which is applied in the direction of testing wear resistance, weather resistance/light resistance/corrosion resistance, measuring devices, etc. Experiment time, the effect of fast conversion measurements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

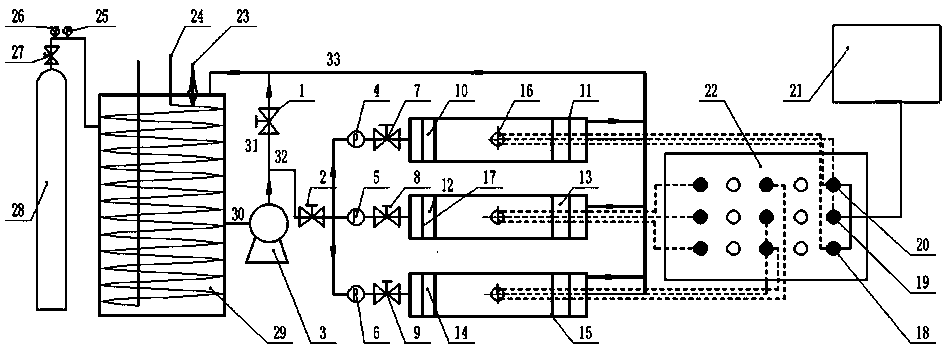

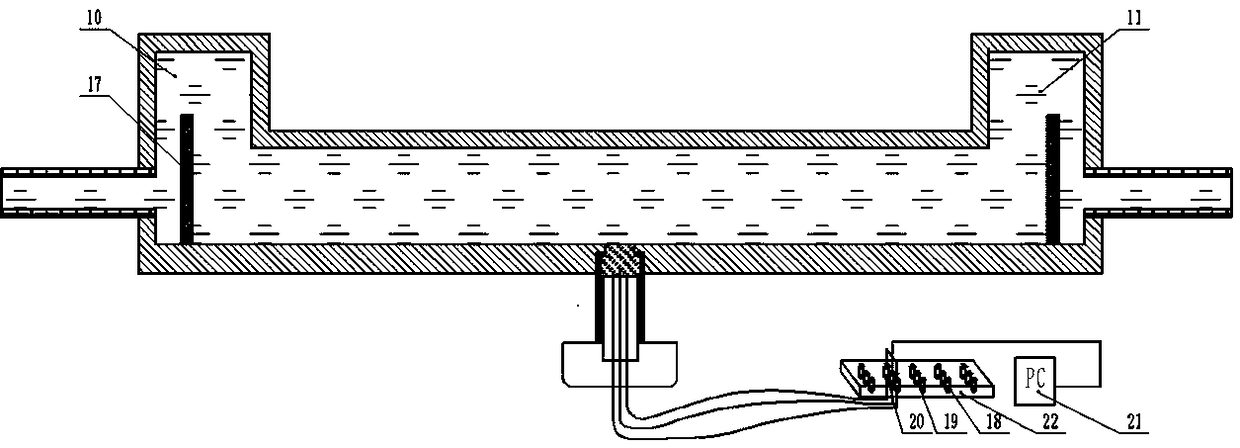

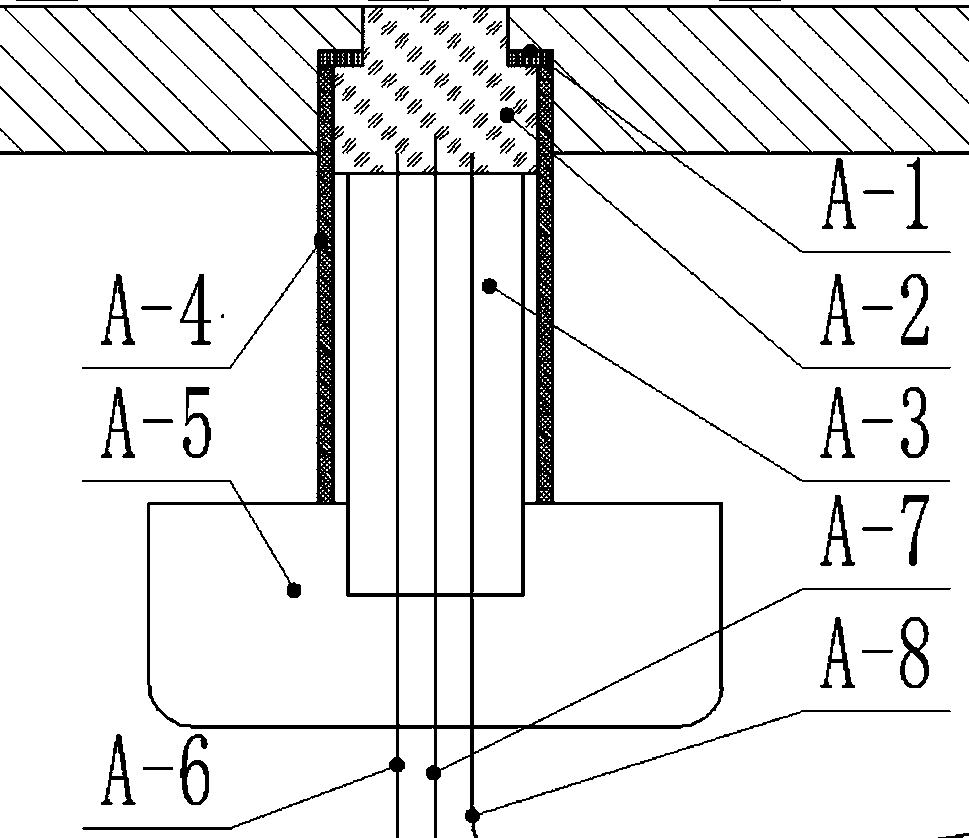

[0034] Refer to attached figure 1 , a multi-channel erosion corrosion test system mentioned in the present invention, its technical solution is: including solution tank (29), cooling coil (24), centrifugal pump (3), pressure gauge (26), gas supply bottle ( 28), pH meter (23), branch test pipeline, test conversion board (22), electrochemical workstation (21); the main inflow pipeline (32) and the main return pipeline (33) respectively have total inflow The valve (1) and the total return valve (2) are used to adjust the flow rate. The solution flows from the solution tank (29) through the main inflow pipeline (32) into multiple branch test pipelines, and passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com