A test device and test method for the meshing ratio of the end gear of the servo tool post

A technology of servo tool holder and testing device, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc. It can solve problems such as toner knocking off, affecting measurement accuracy, ignoring meshing deformation, etc., and achieves force Satisfaction, simple operation, and the effect of eliminating torsional force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

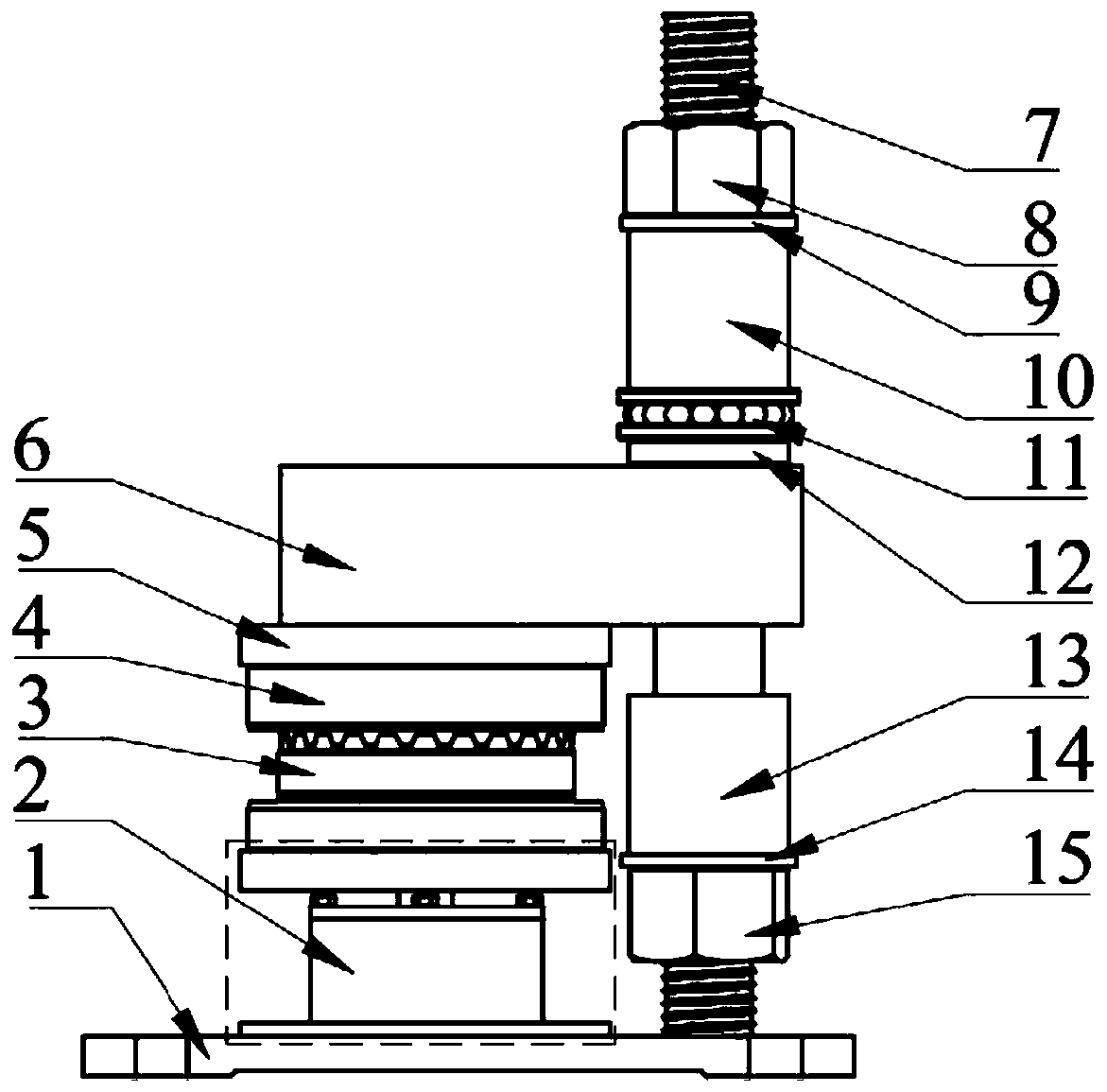

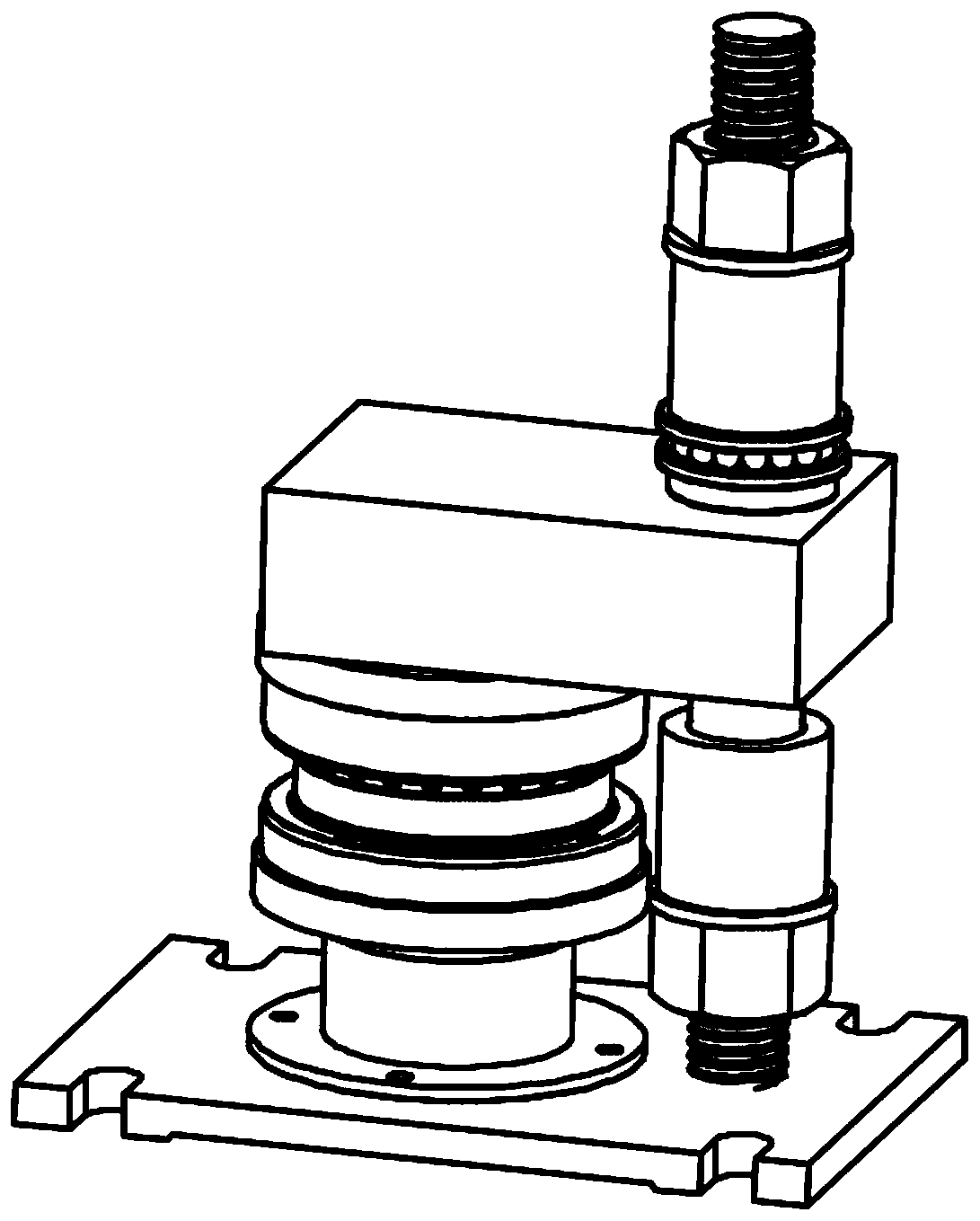

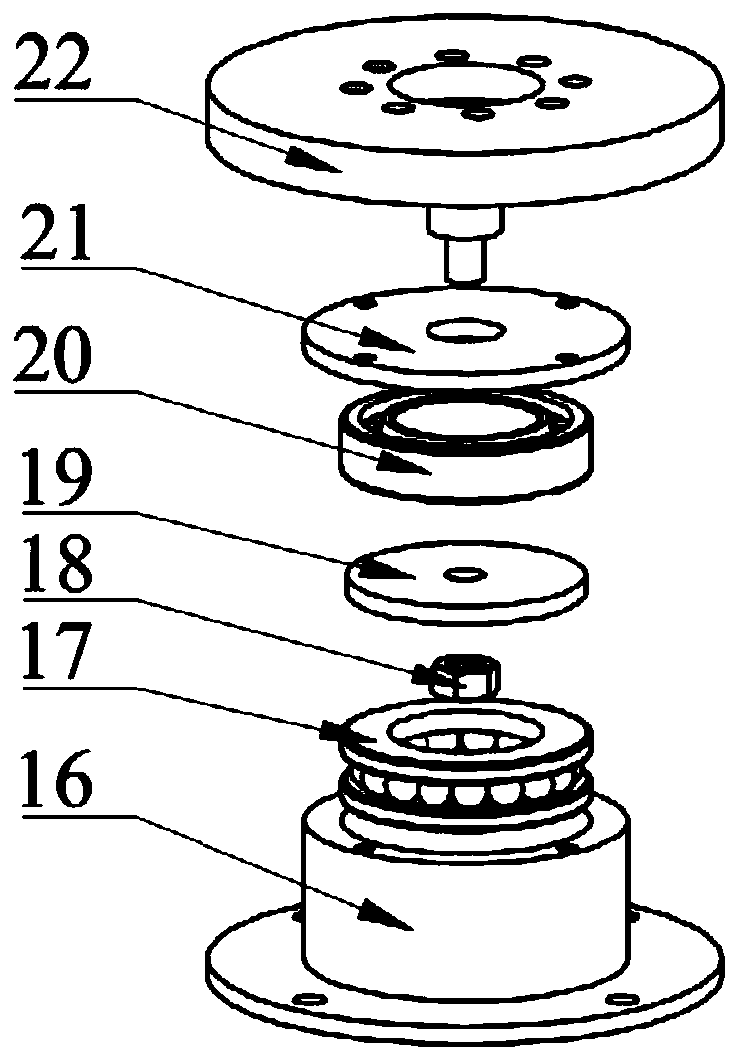

[0038] like Figure 1-8 As shown, a test device for the meshing rate of the servo tool holder end sprocket of the present invention includes a base plate 1 for positioning, a rotating mechanism 2 for installing and detecting the first detection end sprocket 3, and installing another detection second detection end The sliding mechanism of the toothed plate 4 and the executive mechanism that realizes the extrusion and lifting of the slide table 6, the rotating mechanism includes a rotating mechanism base 16, a first thrust ball bearing 17, a connecting nut 18, a connecting plate 19, and an angular contact ball bearing 20 , a cover plate 21 and a turntable 22, the sliding mechanism includes a threaded slide track 7, a slide 6 and a connector 5, the actuator includes an upper nut 8, an upper washer 9, an upper sleeve 10, a second t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com