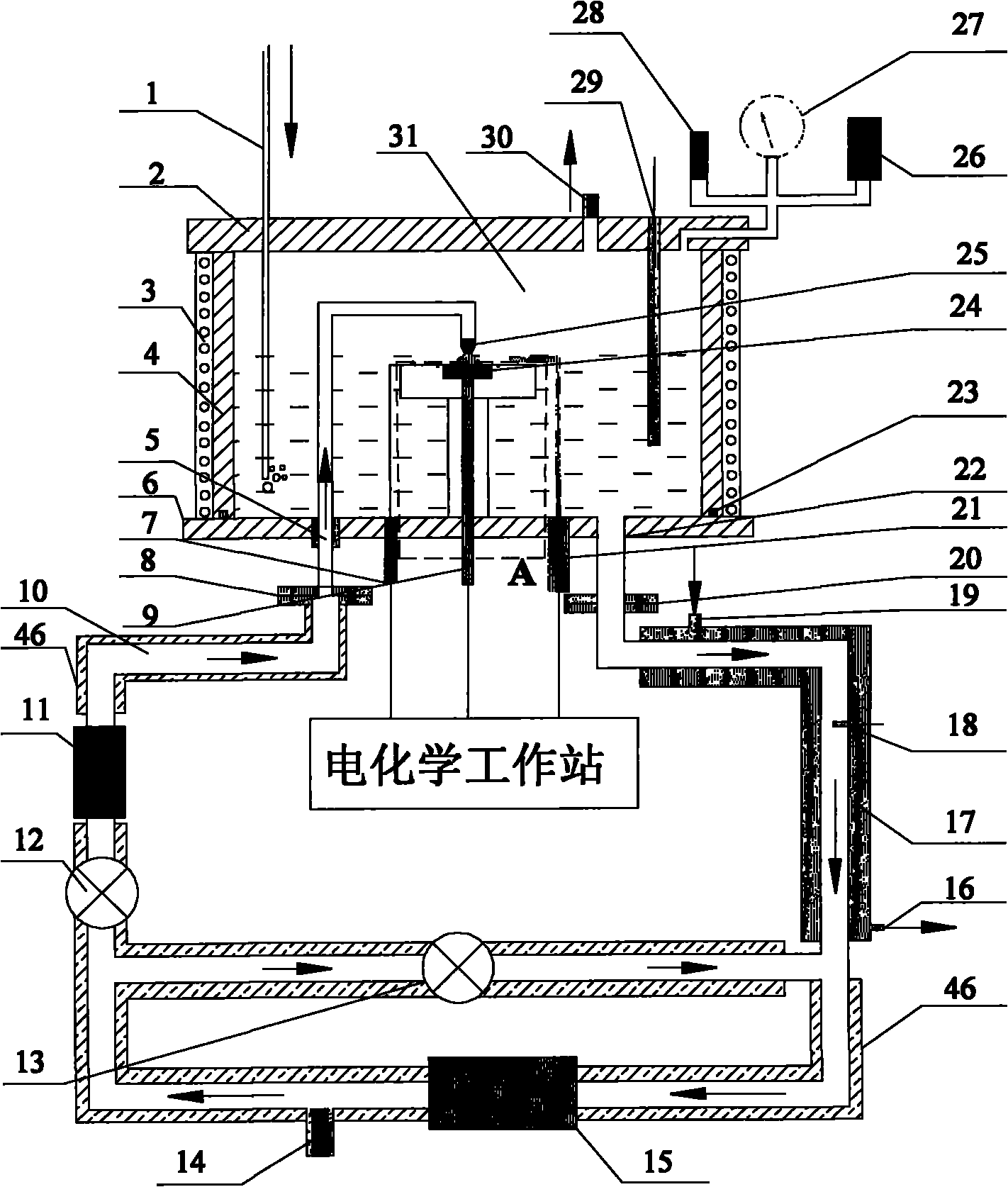

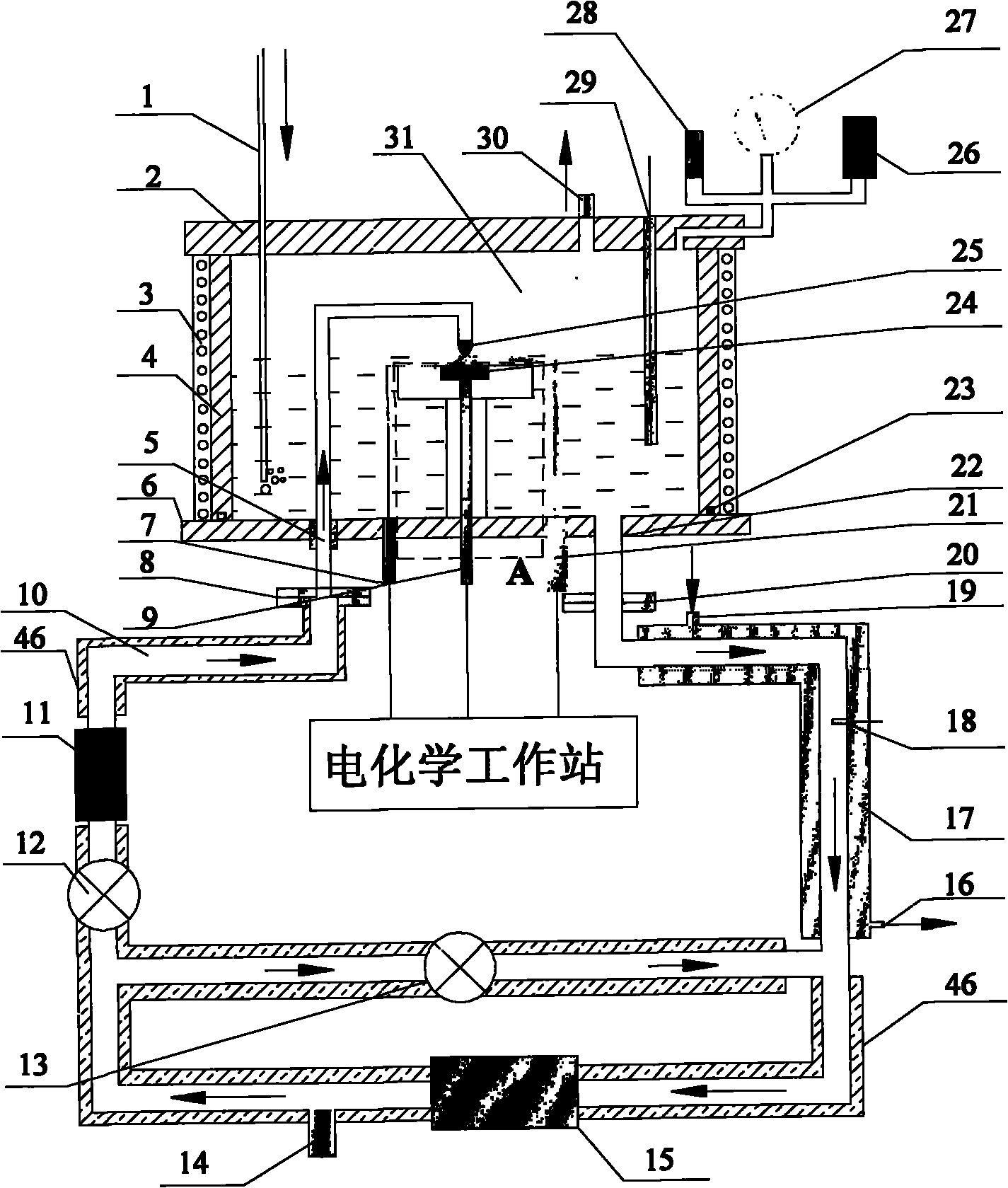

Experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing

A high temperature and high pressure, test experiment technology, applied in the field of electrochemistry, can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

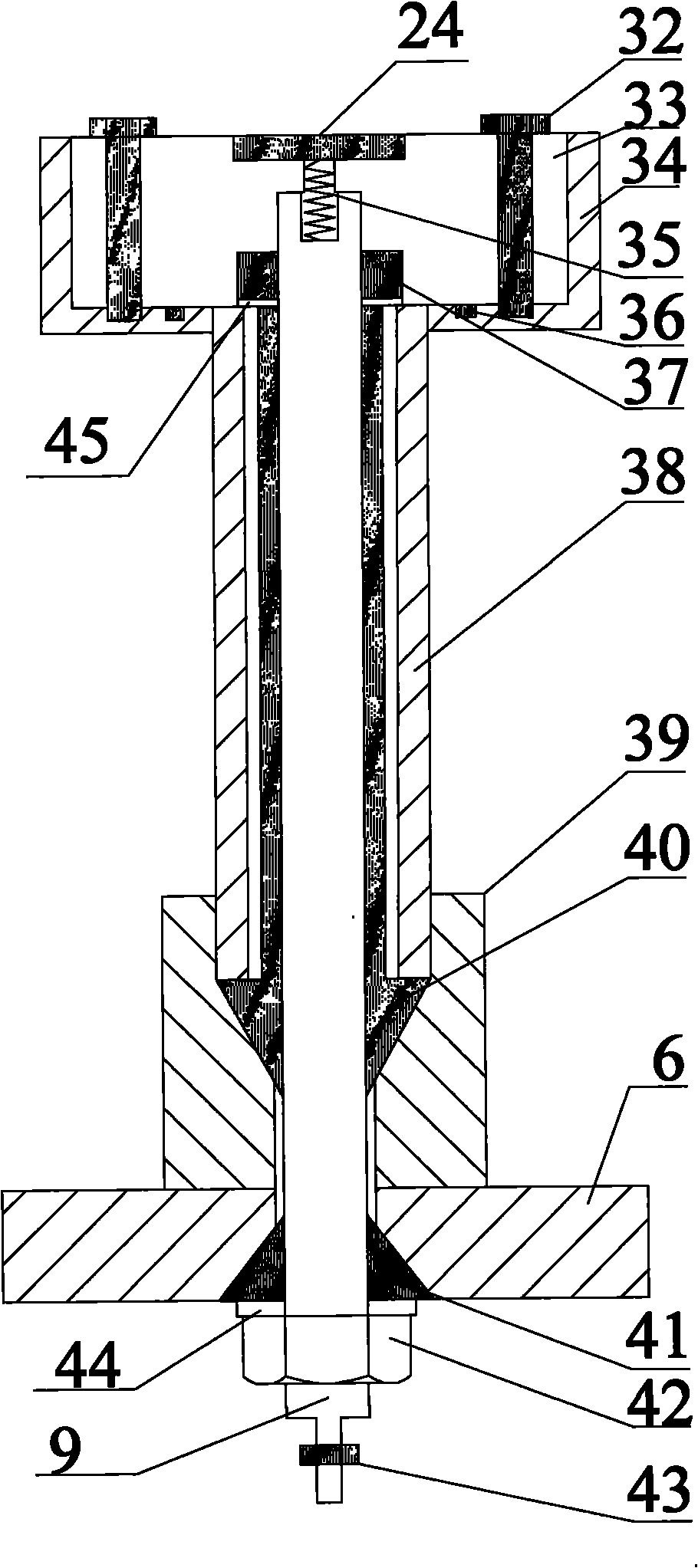

[0011] refer to figure 1 , 2 , which is a high-temperature and high-pressure fluid erosion simulation experiment and electrochemical test experimental device provided according to the above technical characteristics. Open the autoclave upper cover 2 and remove the nozzle 25, fix the processed sample 24 on the sample holder 33, use the polytetrafluorobolt 32 to fix the sample holder 33 on the holder tray 34, and the sample 24 passes through the copper spring 35 is connected with the copper rod 9 to form the working electrode in the three-electrode system, and the nozzle 25 is installed. Pour a certain volume of dielectric solution into the autoclave 31, and open the liquid outlet 14 in the circulation loop 10 at the same time to drain the gas in the device. The liquid level of the medium solution should be higher than the upper surface of the sample 24. Put on the lid of the autoclave 2. Gas N was introduced from the gas inlet 1 of the autoclave 2 After deoxygenation for mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com