Mud-stone flow discharge guiding groove based on step anti-flushing notched sill group and use thereof

An anti-scour and debris flow technology, applied in hydraulic engineering, marine engineering, construction, etc., can solve the problems of blocking the connection of aquatic organisms up and down, unfavorable ecological restoration of ditch beds, low bulk density of debris flow, etc. The effect of ecological restoration of the channel, which is beneficial to the operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

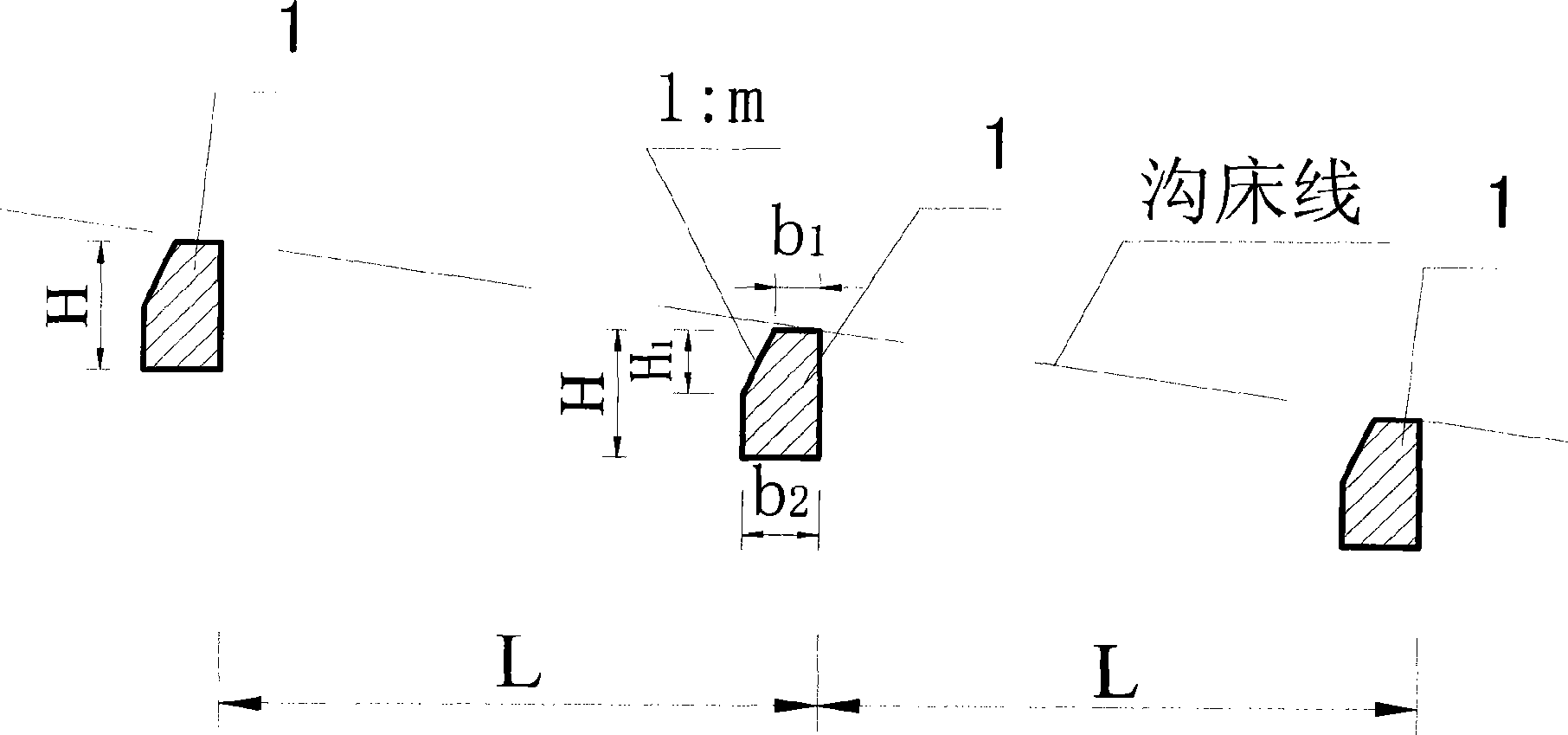

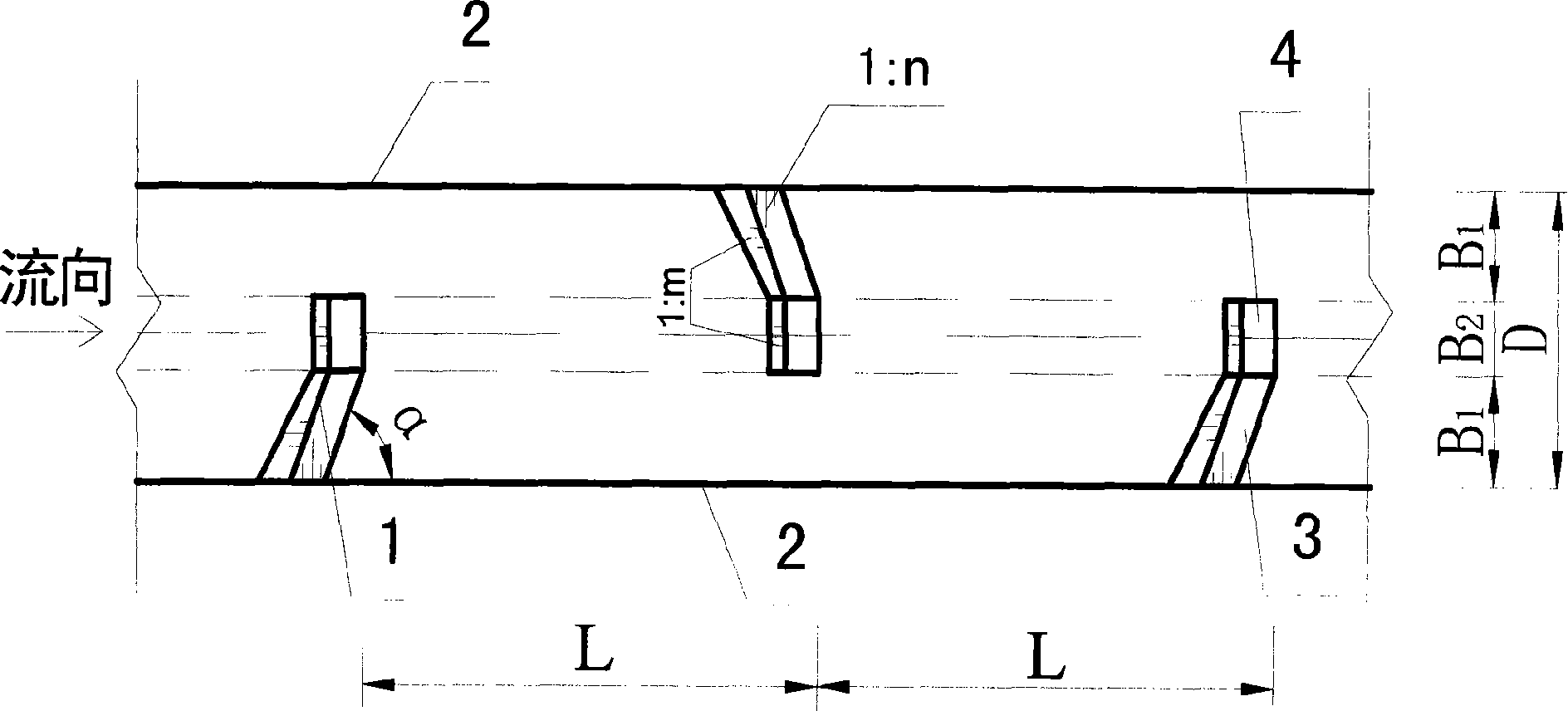

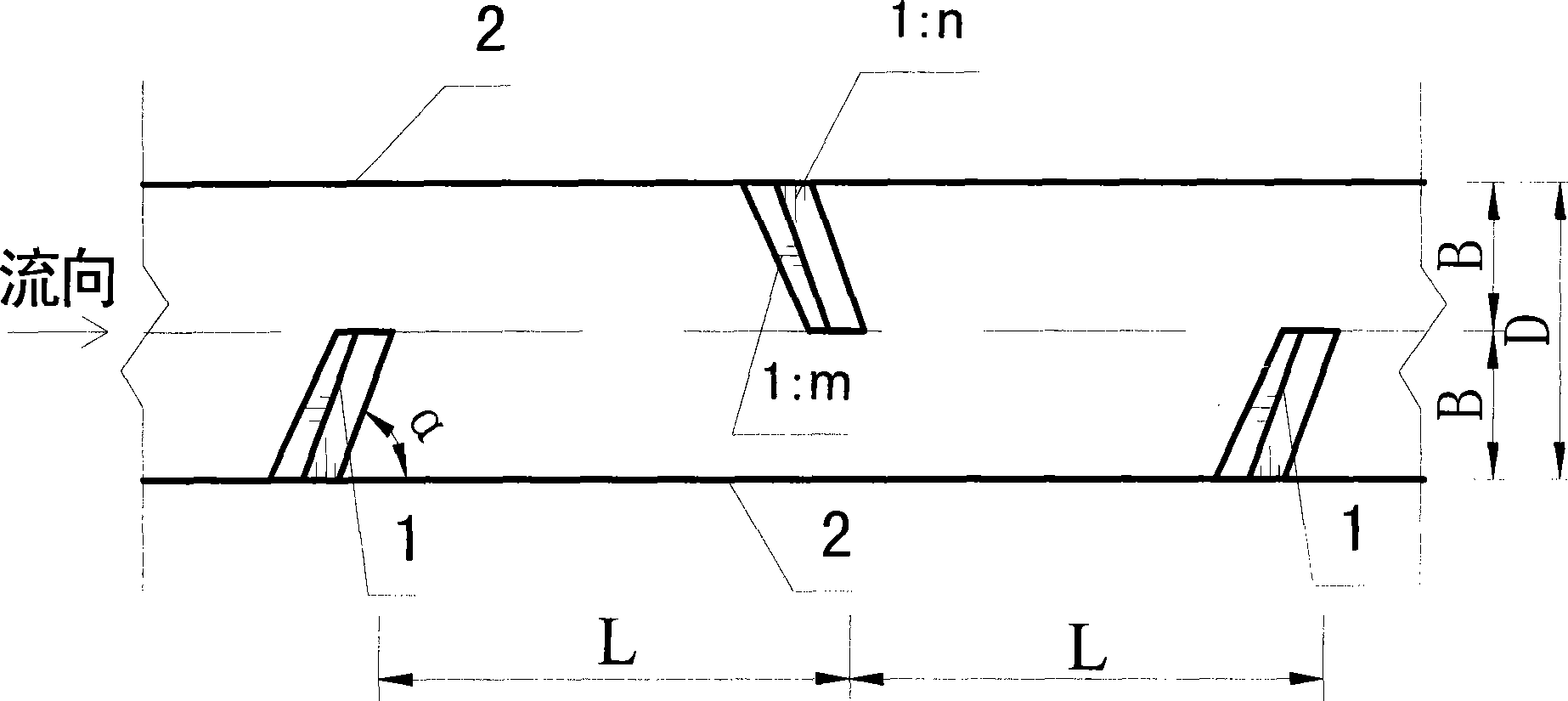

[0035] like figure 1 , figure 2 , Figure 5 shown. For a watershed area of 1.0km 2 , The accumulation fan slope is 16%. On the debris flow accumulation fan, the debris flow drainage channel based on the stepped anti-scour tooth sill group includes the beam side wall 2 and the stepped anti-scour tooth sill group placed therebetween, connected with it, and used in conjunction with the stepped anti-scour tooth sill group. The sill group is composed of a number of scour-proof tooth sills 1 with a certain interval and a certain buried depth. The burial depth H of the anti-scouring tooth sills 1 is 2.5m, and the distance L between the anti-scouring tooth sills 1 is 4.0m.

[0036] The lateral length B of the anti-scour tooth sills 1 forming the step anti-scour tooth sill group in the vertical direction of the beam side wall 2 is smaller than the width D of the debris flow drainage channel, and the anti-scour tooth sills forming the step anti-scour tooth sill group The scouri...

Embodiment 2

[0039] like figure 1 , image 3 , Figure 6 shown. For a watershed area of 8.0km 2 , The slope of the accumulation fan is 10%. The similarities with Embodiment 1 will not be repeated, and the difference is that the burial depth H of the anti-scour sills 1 is 1.8 m, and the distance L between the anti-scour sills 1 is 8.0 m.

[0040] at P 2% Under the design standard, the debris flow flow rate of the drainage channel is 68.0m 3 / s, D takes 5.0m, B takes 2.5m; inclination angle α takes 70°; slope gradient 1:n takes 1:10; top width b 1 Take 1.0m, bottom width b 2 Take 1.5m, and take 1:0.8 for the slope of the upstream side as 1:m. h 1 Take 0.63m.

Embodiment 3

[0042] like figure 1 , Figure 4 , Figure 7 shown. For a basin area of 30.0km 2 , The slope of the accumulation fan is 5%. The same as the first embodiment will not be repeated, and the difference is that: the burial depth H of the anti-scour sills 1 is 1.5 m, and the distance L between the anti-scour sills 1 is 15.0 m.

[0043] at P 2% Under the design standard, the debris flow flow rate of the drainage channel is 185.0m 3 / s, D takes 16.0m, B takes 6.0m; inclination angle α takes 85°; slope gradient 1:n takes 1:20; top width b 1 Take 1.5m, bottom width b 2 Take 2.0m, and take 1:1 for the gradient 1:m at the upstream side. h 1 Take 0.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com