Debris flow guiding slot based on step anti-erosion toothed sill group and application thereof

An anti-scouring and debris flow technology, which is applied in the field of debris flow drainage channels, can solve the problems of providing sufficient guarantee for the stability of the side wall of the beam flow, potential safety hazards of the side walls of the drainage channel, and increasing the buried depth of the side wall foundation, so as to reduce erosion Destructive capacity, reduced operation and maintenance costs, and the effect of preventing ditch bed sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

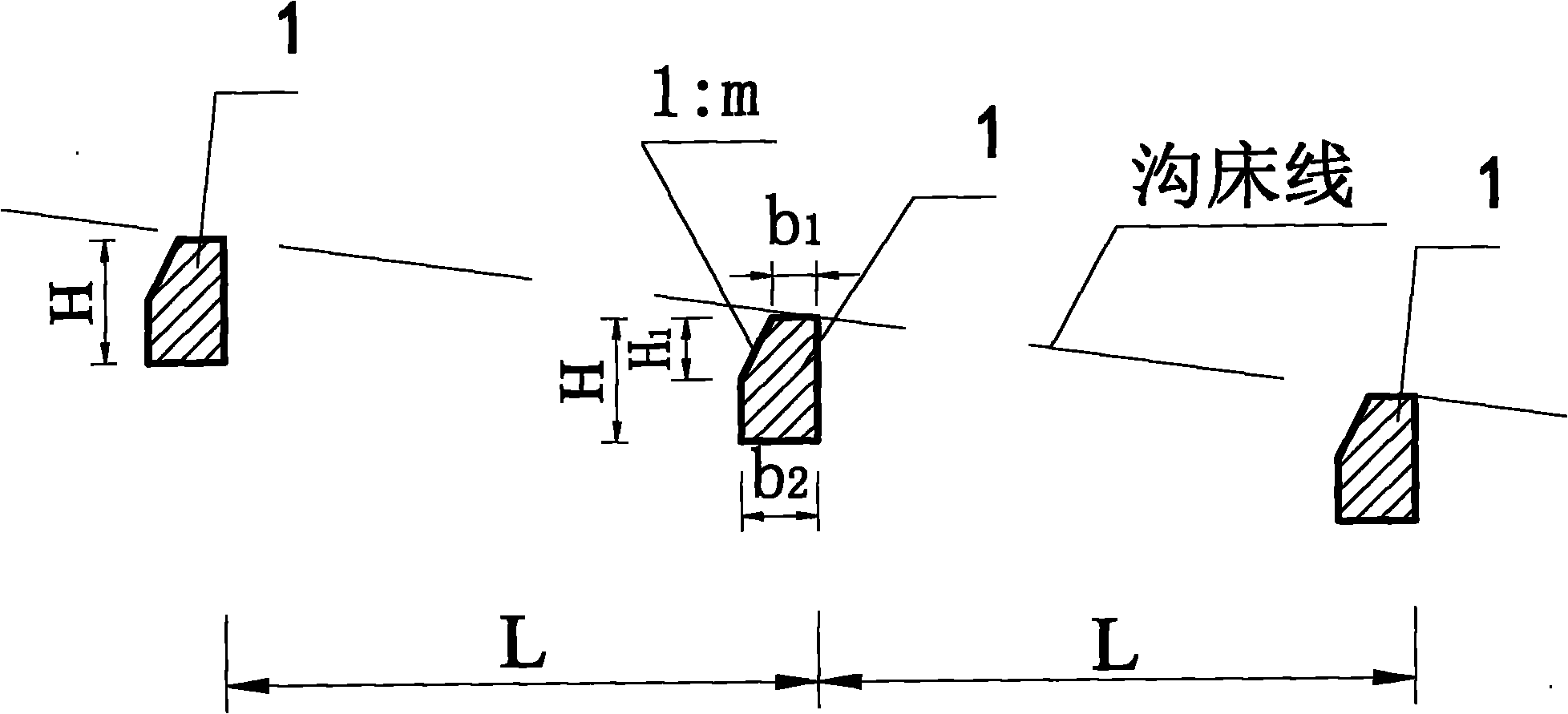

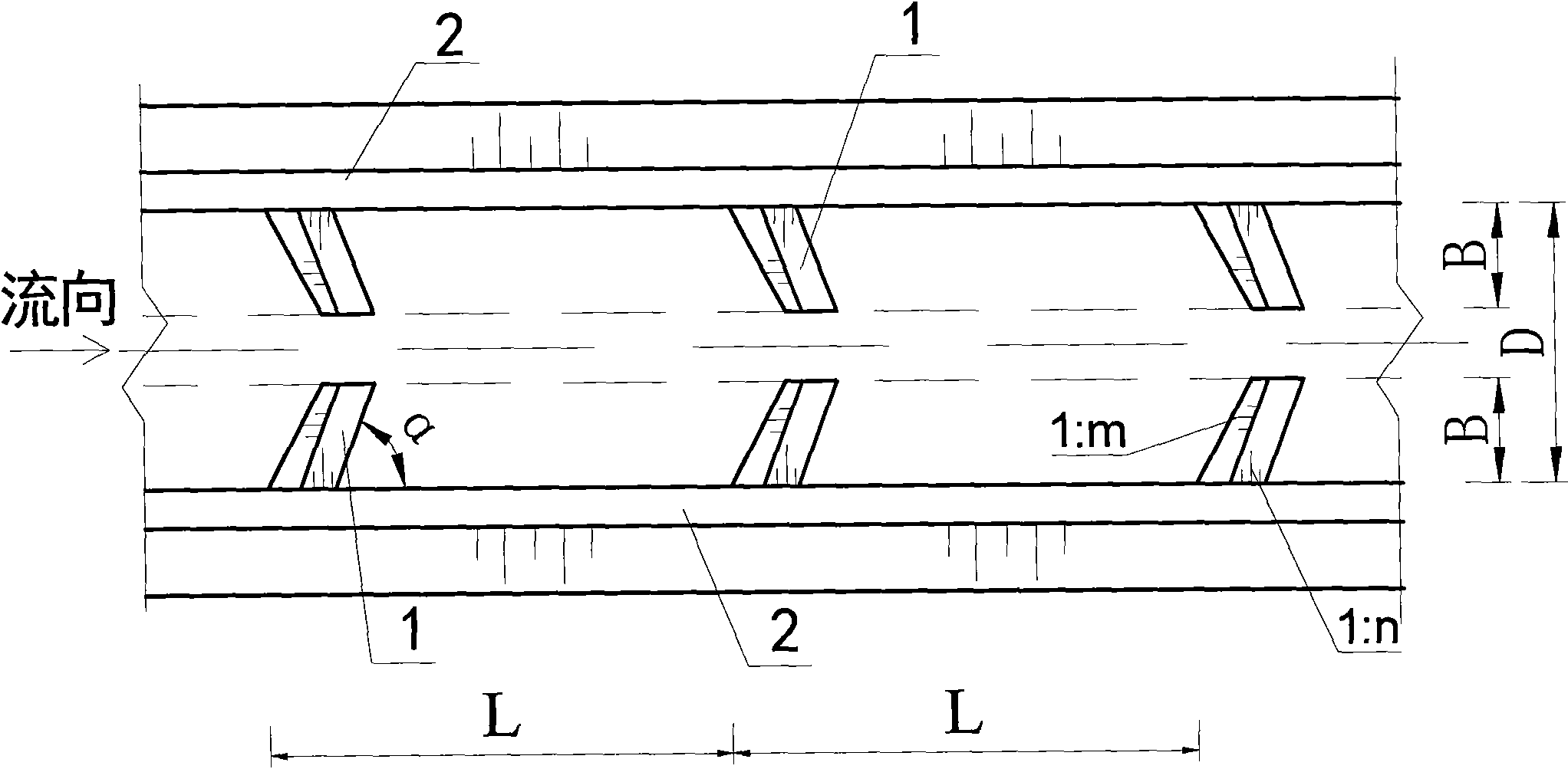

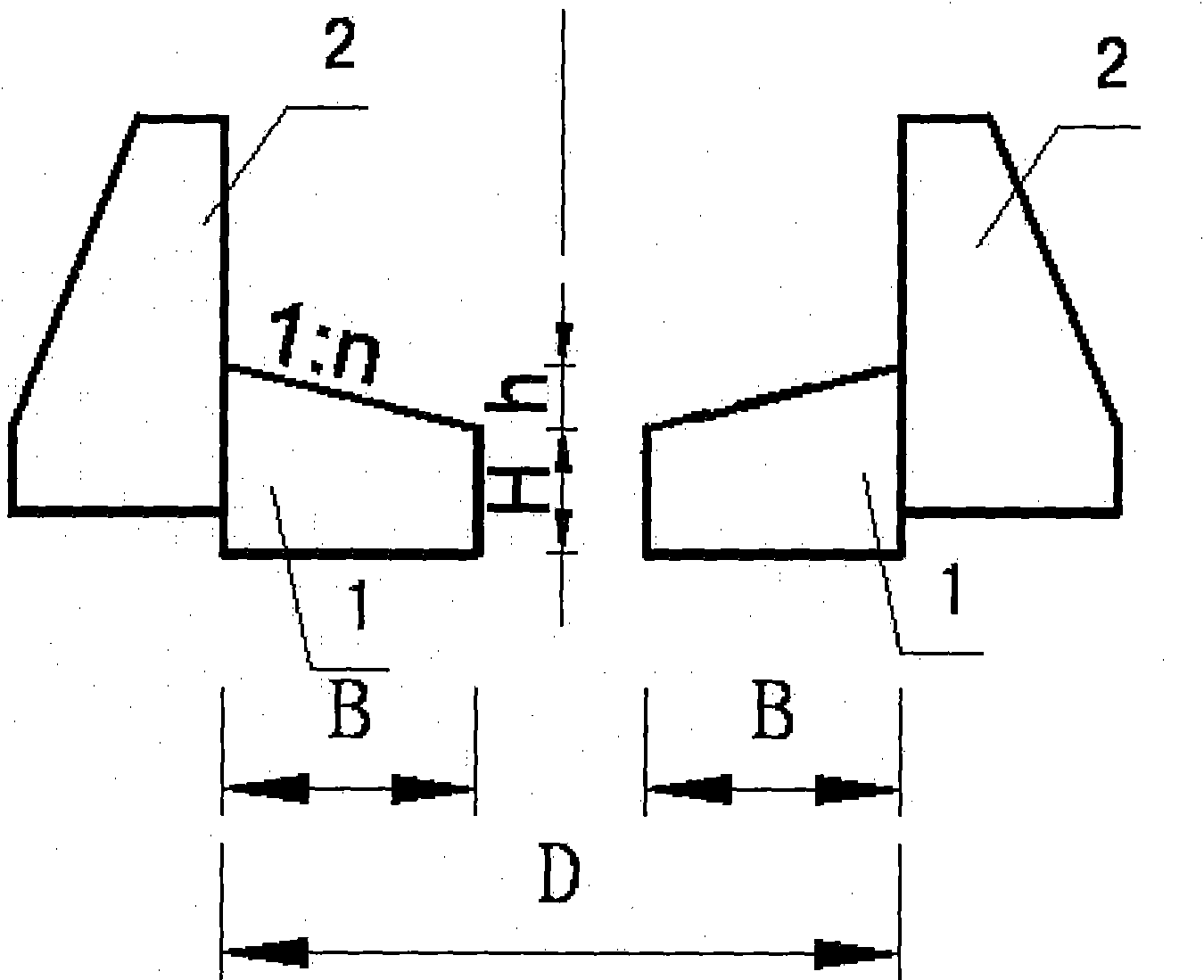

[0031] Such as figure 1 , figure 2 , image 3 shown. For a watershed area of 2.0km 2 , The slope of the accumulation fan (that is, the slope of the ditch bed) is 12%. Under the design standard, dilute debris flow, water-rock flow and flash flood are mainly considered. On the debris flow accumulation fan, the debris flow drainage channel based on the symmetrical stepped anti-scour tooth sill group includes the beam side wall 2 and the stepped anti-scour tooth sill group placed therebetween, connected to it, and used in conjunction with it. The step anti-scour Every two steps of the tooth sill group are distributed at a certain interval, and the step anti-scour tooth sill group is composed of several anti-scour tooth sills 1 with a certain buried depth. The distance L between every two steps of the anti-scour tooth sill group is 8.0m, and the buried depth H of the anti-scour tooth sill 1 is 2.5m.

[0032] The two anti-scour tooth sills 1 are symmetrically distributed betw...

Embodiment 2

[0035] Such as figure 1 , figure 2 , image 3 shown. For a watershed area of 20.0km 2 , The slope of the accumulation fan is 3%. Under the design standard, water, rock flow and mountain torrent are mainly considered. The same as the first embodiment will not be repeated, the difference is that: the distance L between every two steps of the anti-scouring tooth sill group of the steps is 25.0m, and the buried depth H of the anti-scouring tooth sill 1 is 1.5m .

[0036] at P 2% Under the design standard, the debris flow flow rate of the drainage channel is 100.0m 3 / s, D takes 16.0m, B takes 1.6m; inclination angle α takes 45°; slope gradient 1:n takes 1:20; top width b 1 Take 1.5m, bottom width b 2 Take 2.0m, and take 1:1 for the gradient 1:m at the upstream side. h 1 Take 0.5m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com