Vibration fatigue life prediction method for gas storage gas injection string

A vibration fatigue and life prediction technology, applied in construction and other directions, can solve problems such as affecting the safe production of gas storage, oil pipe fatigue fracture, etc., and achieve the effect of improving the prediction and monitoring mechanism and the real monitoring data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Analysis of the force of the fluid flowing in the pipe string on the pipe string:

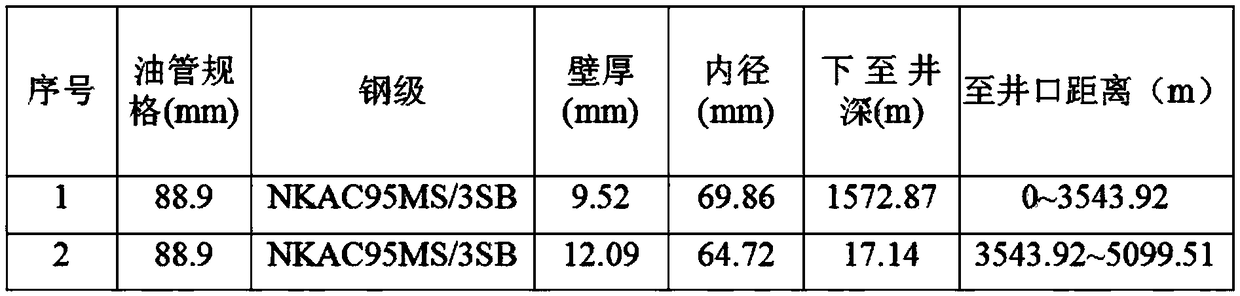

[0024] Taking a gas storage as an example for analysis, the maximum inclination angle of the well is 87°, and VM80S steel grade Φ177.8mm×10.36mm tubing is used for gas injection and production. The elastic modulus of the pipe is 206GPa, the Poisson's ratio is 0.3, and the density is 7800kg / m 3 , the acceleration of gravity is 9.8m / s 2 . Considering that the gas injection medium of this well is natural gas, the relative density of natural gas is taken as 0.55g / cm 3 . Establish the flow field analysis of natural gas flowing through the changing area of the tubing string section and the pressure distribution diagram of the natural gas acting on the tubing string. In the connection area of two oil pipes, the absolute pressure of the fluid changes regularly. When the natural gas passes through the changing section of the tubing string, that is, the section changes suddenly, the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com