Expanded flexible well cementing grout and preparation method thereof

A technology of cementing slurry and toughness, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of difficult mixing, high price, poor cementing ability, etc., to improve the packing density and reduce transmission coefficient, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

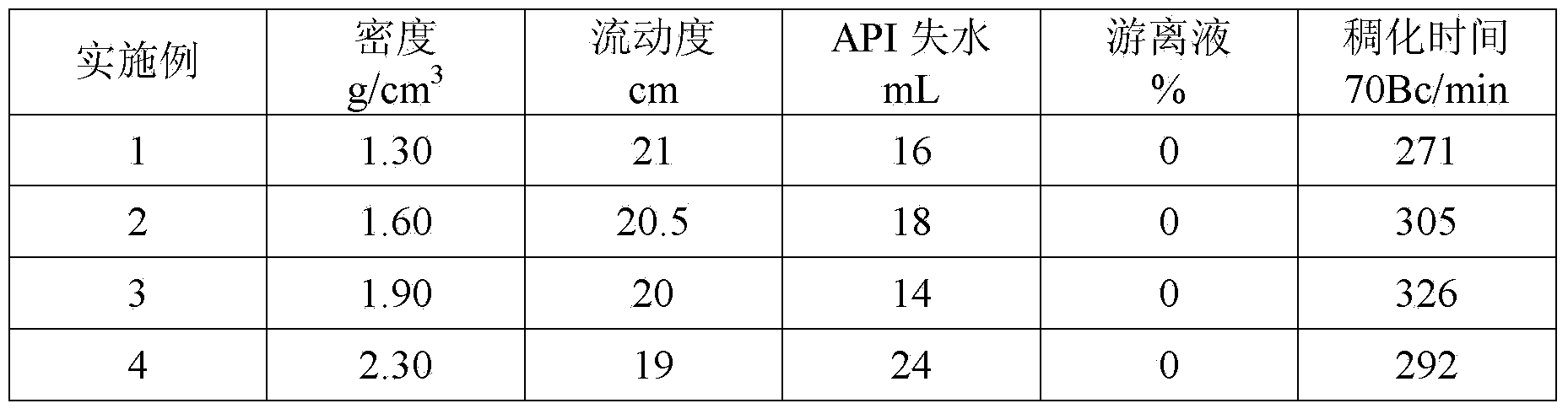

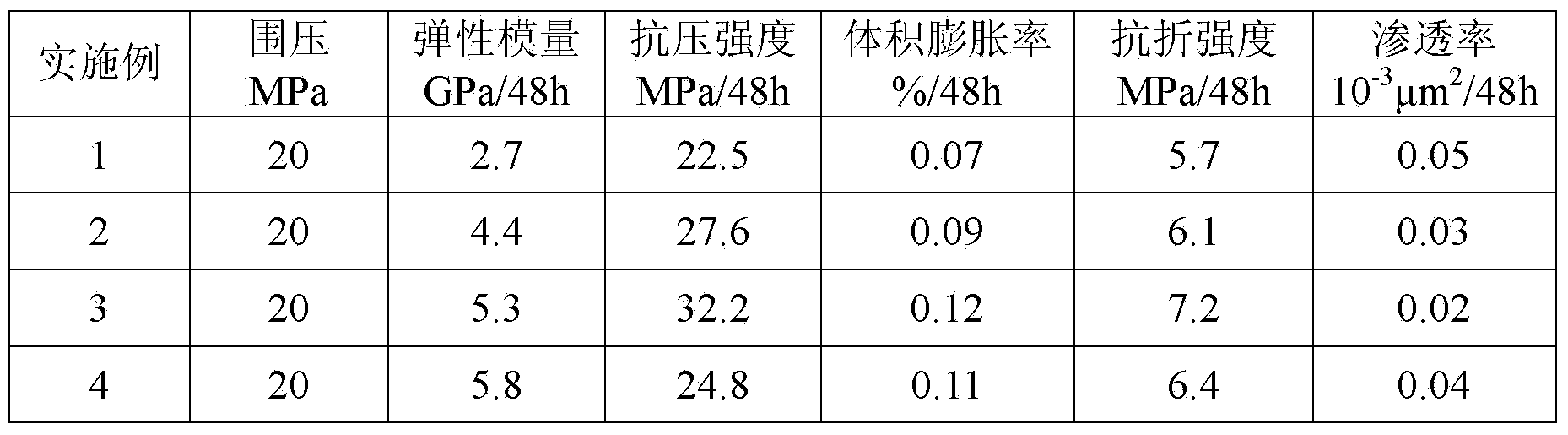

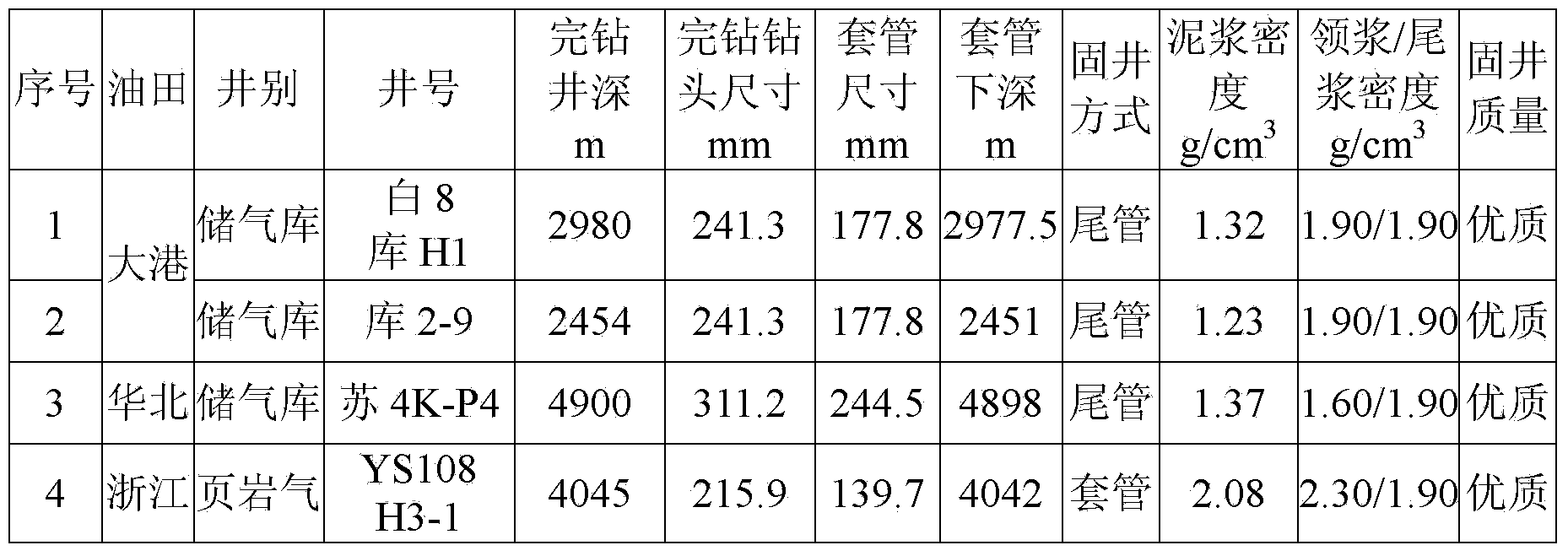

Examples

Embodiment 1

[0031] This embodiment provides an expansive toughness cementing cement slurry, which comprises the following components in parts by weight: 100 parts by weight of cement, 6 parts by weight of a graded mixture of modified nitrile rubber powder, 20 parts by weight of slag powder, powder A graded mixture of coal ash, superfine cement, metakaolin, 39 parts by weight of glass microspheres, 0.8 parts by weight of bentonite, 95 parts by weight of distilled water, 1 part by weight of aldehyde and ketone condensate dispersant, 3.2 parts by weight of PVA fluid loss reducer, 1.2 parts by weight of AMPS polymer retarder, 0.5 parts by weight of silicone foam suppressor, and 0.5 parts by weight of tributyl phosphate.

[0032] The preparation method of the above-mentioned expansive toughness cementing slurry, it comprises the following steps:

[0033] The graded mixture of 6 parts by weight of modified nitrile rubber powder, 20 parts by weight of slag powder, fly ash, superfine cement, the ...

Embodiment 2

[0037] This embodiment provides an expansive toughness cementing cement slurry, which comprises the following components in parts by weight: 100 parts by weight of cement, 8 parts by weight of a graded mixture of modified nitrile rubber powder, 28 parts by weight of slag powder, powder A graded mixture of coal ash, superfine cement, metakaolin, 12 parts by weight of glass microspheres, 0.5 parts by weight of bentonite, 72 parts by weight of distilled water, 1 part by weight of aldehyde and ketone condensate dispersant, 3 parts by weight of PVA fluid loss reducer, 1.5 parts by weight of AMPS polymer retarder, 0.5 parts by weight of silicone foam suppressor, and 0.5 parts by weight of tributyl phosphate.

[0038] The preparation method of the above-mentioned expansive toughness cementing slurry, it comprises the following steps:

[0039] The graded mixture of 8 parts by weight of modified nitrile rubber powder, 28 parts by weight of slag powder, fly ash, superfine cement, the gr...

Embodiment 3

[0043] This embodiment provides an expansive toughness cementing cement slurry, which comprises the following components in parts by weight: 100 parts by weight of cement, 11 parts by weight of a graded mixture of modified nitrile rubber powder, 4 parts by weight of slag powder, powder Coal ash, superfine cement, graded mixture of metakaolin, 35 parts by weight of quartz sand, 55 parts by weight of distilled water, 1 part by weight of aldehyde and ketone condensate dispersant, 2.5 parts by weight of PVA fluid loss reducer, 2.5 parts by weight of AMPS polymer Retarder, 0.5 parts by weight organosilicon foam suppressor, 0.5 parts by weight tributyl phosphate.

[0044] The preparation method of the above-mentioned expansive toughness cementing slurry, it comprises the following steps:

[0045] A gradation mixture of 11 parts by weight of modified nitrile rubber powder, 4 parts by weight of slag powder, fly ash, superfine cement, a gradation mixture of metakaolin, 35 parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com