Multi-well coordinating frequency-conversion control oil pumping unit system

A frequency conversion control and frequency conversion control cabinet technology, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc., can solve the problems of normal winding interference, occupying ground space, unable to work normally, etc., to reduce erosion damage, reduce Maintenance costs and the effect of extending the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

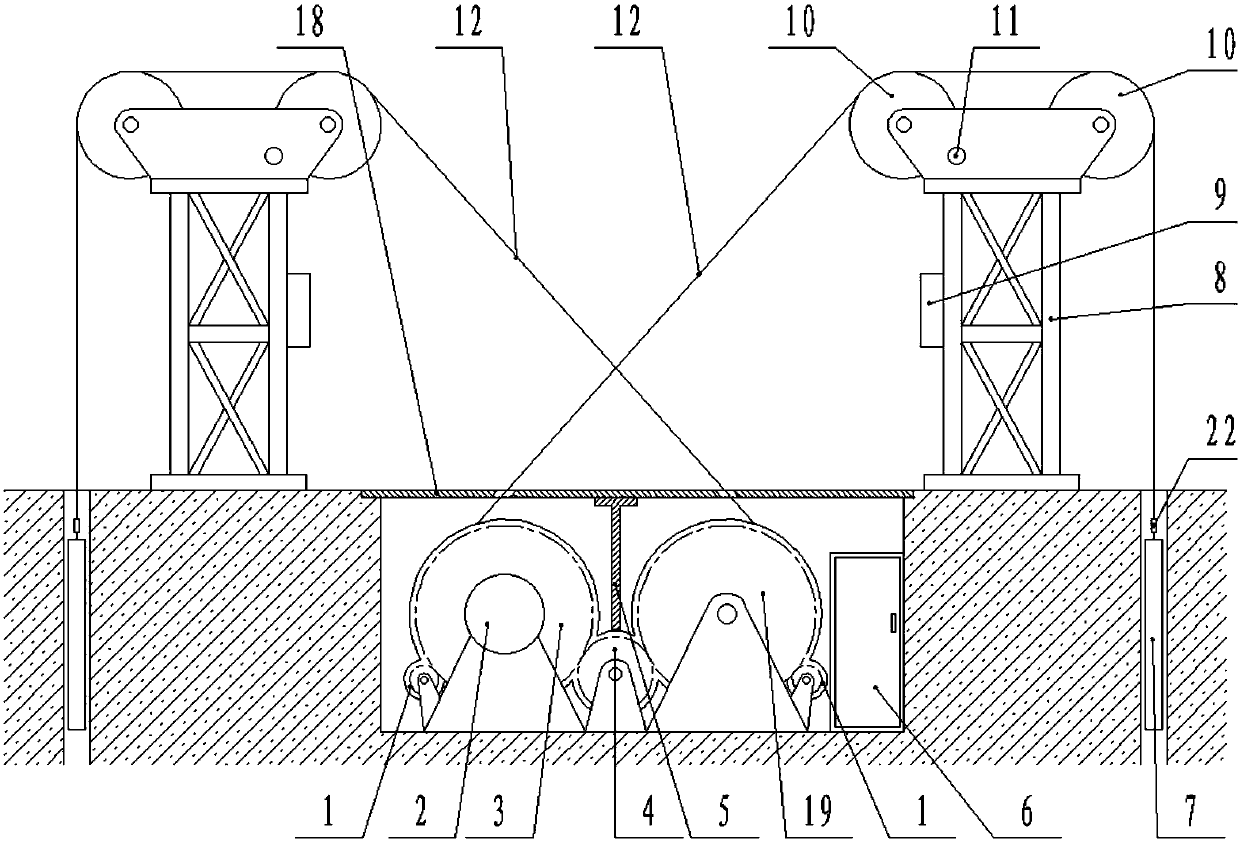

[0020] The present invention will be further described below in conjunction with accompanying drawing:

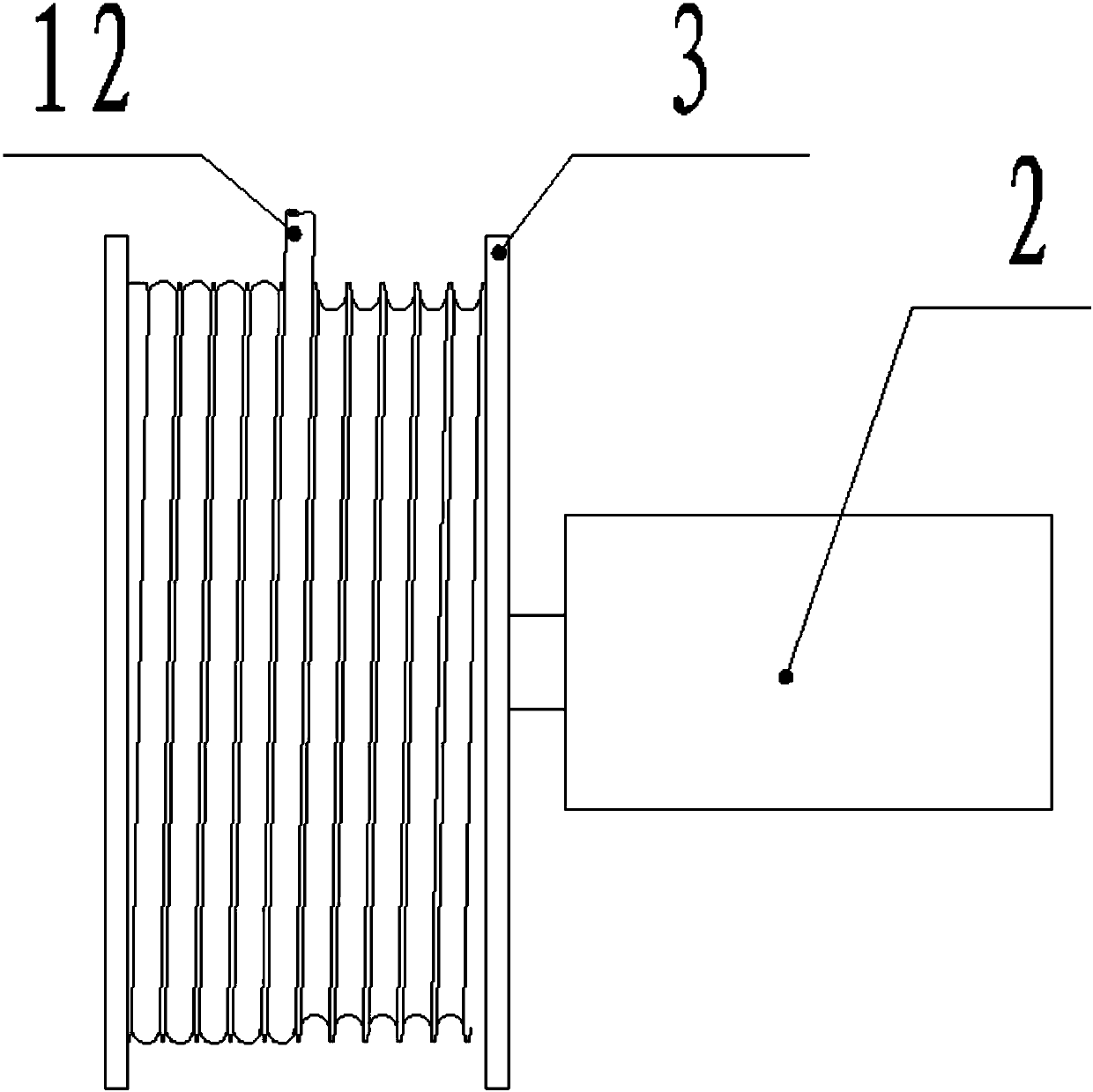

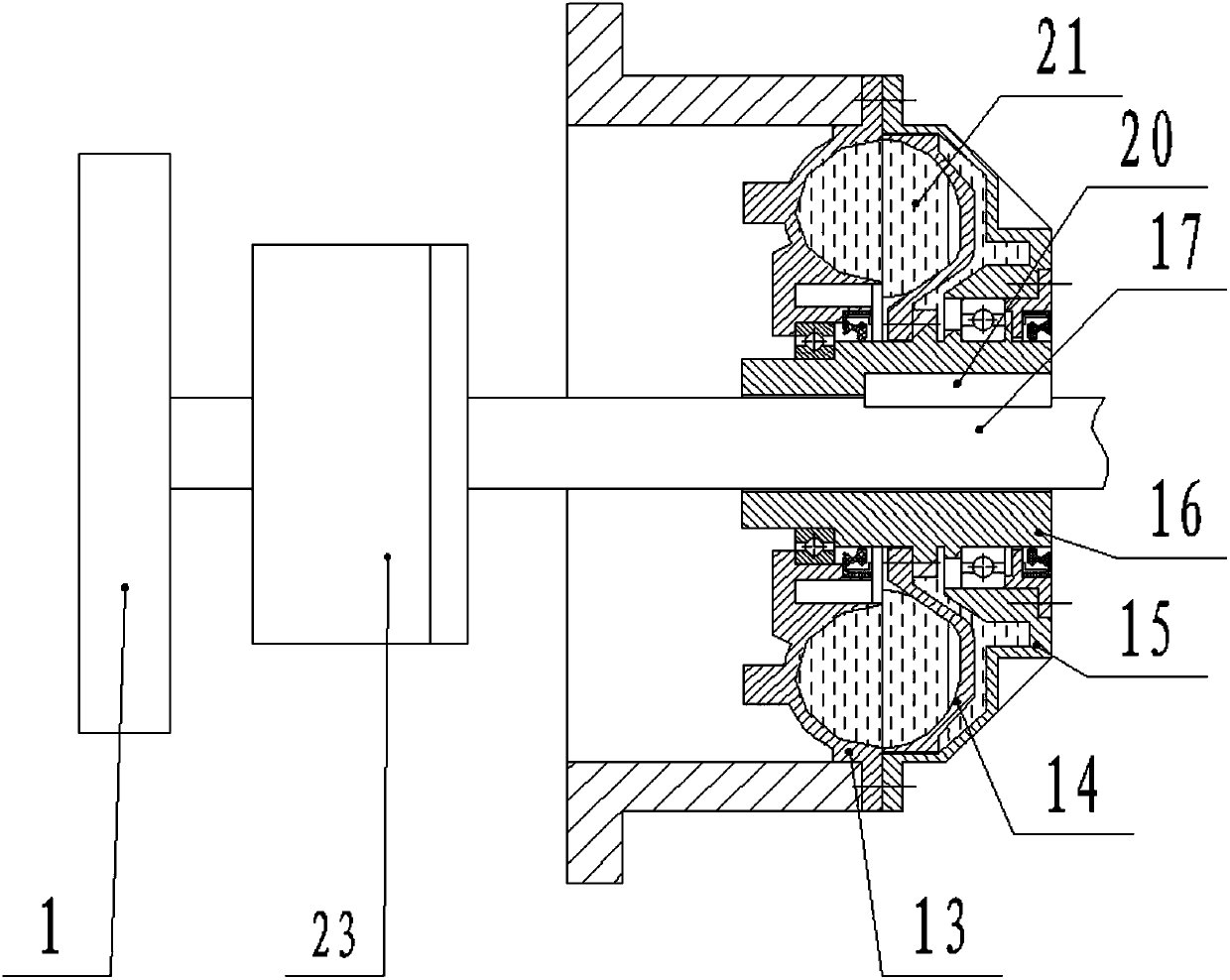

[0021] The present invention comprises driving device, oil extraction rope 12, oil well pump 7, derrick 8 and frequency conversion control cabinet 6, and driving device comprises motor 2, deceleration mechanism and reel, and motor 2 drives reel to rotate through deceleration mechanism, and described oil pumping One end of the rope 12 is wound on the reel, and the other end goes around the fixed pulley 10 on the top of the derrick 8 and is connected with the plunger in the downhole oil pump 7. There are two oil ropes 12. Correspondingly, the derrick 8 All have two covers with oil well pump 7 respectively. The above are conventional structures that already exist in the prior art, and will not be repeated here.

[0022] On the most primitive pumping unit, all the power components, transmission components and electric control components were set above the ground, and subsequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com