Anti-corrosion saline-alkaline-tolerant concrete and preparation method thereof

A concrete and saline-alkali-resistant technology, applied in the field of corrosion-resistant concrete, can solve problems such as the decline of anti-corrosion effect, and achieve the effect of reducing erosion damage and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

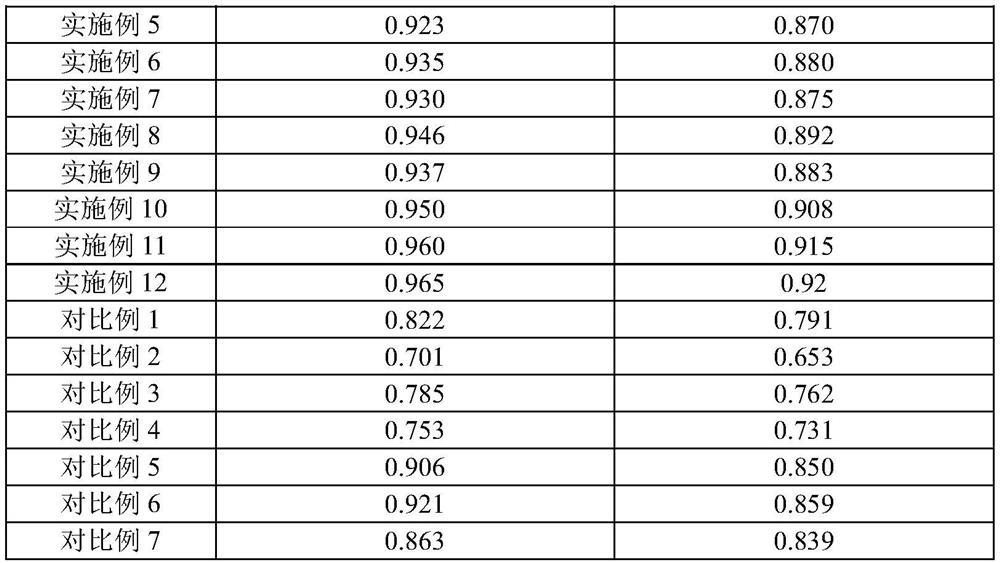

Examples

Embodiment 1

[0035] The anti-corrosion and salt-alkali-resistant concrete of this embodiment is made of the following raw materials: aggregate 1500kg, sand 600kg, cement 150kg, fly ash 50kg, silica fume 20kg, fiber 5kg, water 100kg, water reducing agent 6kg, expansion agent 2kg, preservative 12kg.

[0036] Among them, the preservative is composed of ethylenediamine oleate, bisphenol A diallyl ether, and β-diketone compound in a mass ratio of 10:10:5. Aggregate is 10-25cm continuous gradation. The cement is ordinary Portland cement, grade 42.5r. Fly ash is a first-class fly ash. The fibers are polypropylene fibers with an average length of 25 mm. The water reducer is a high-efficiency polycarboxylate water reducer. The expansion agent is light-burned magnesium oxide. The β-diketone compound is ethyl acetoacetate.

[0037] The preparation method of the anticorrosion saline alkali resistant concrete of the present embodiment, comprises the steps:

[0038] S1: Weigh the corresponding ra...

Embodiment 2

[0041] The anti-corrosion and salt-alkali-resistant concrete of this embodiment is made of the following raw materials: aggregate 1800kg, sand 800kg, cement 200kg, fly ash 80kg, silica fume 35kg, fiber 10kg, water 130kg, water reducing agent 8kg, expansion agent 5kg, preservative 25kg.

[0042] Among them, the preservative is composed of ethylenediamine oleate, bisphenol A diallyl ether, and β-diketone compound in a mass ratio of 15:17:7. Aggregate is 10-25cm continuous gradation. The cement is ordinary Portland cement, grade 42.5r. Fly ash is a first-class fly ash. The fibers are polypropylene fibers with an average length of 25 mm. The water reducer is a high-efficiency polycarboxylate water reducer. The expansion agent is light-burned magnesium oxide.

[0043] The preparation method of the anticorrosion saline alkali resistant concrete of the present embodiment, comprises the steps:

[0044] S1: Weigh the corresponding raw materials according to the formula amount, mi...

Embodiment 3

[0047]The anti-corrosion and salt-alkali-resistant concrete of this embodiment is made of the following raw materials: aggregate 1650kg, sand 700kg, cement 180kg, fly ash 60kg, silica fume 30kg, fiber 8kg, water 120kg, water reducing agent 7kg, expansion agent 3.5kg, preservative 20kg.

[0048] Among them, the preservative is composed of ethylenediamine oleate, bisphenol A diallyl ether, and β-diketone compound in a mass ratio of 12:16:5.5. Aggregate is 10-25cm continuous gradation. The cement is ordinary Portland cement, grade 42.5r. Fly ash is a first-class fly ash. The fibers are polypropylene fibers with an average length of 25 mm. The water reducer is a high-efficiency polycarboxylate water reducer. The expansion agent is light-burned magnesium oxide.

[0049] The preparation method of the anticorrosion saline alkali resistant concrete of the present embodiment, comprises the steps:

[0050] S1: Weigh the corresponding raw materials according to the formula amount, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com