Through hole ash blowing device used in mechanical part machining

A technology of soot blowing device and mechanical parts, applied in the direction of cleaning method using gas flow, transportation and packaging, pollution prevention method, etc., can solve problems such as difficult transportation, time waste, and long time consumption, and achieve safe and convenient use, reduce Erosion damage, reducing the effect of time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

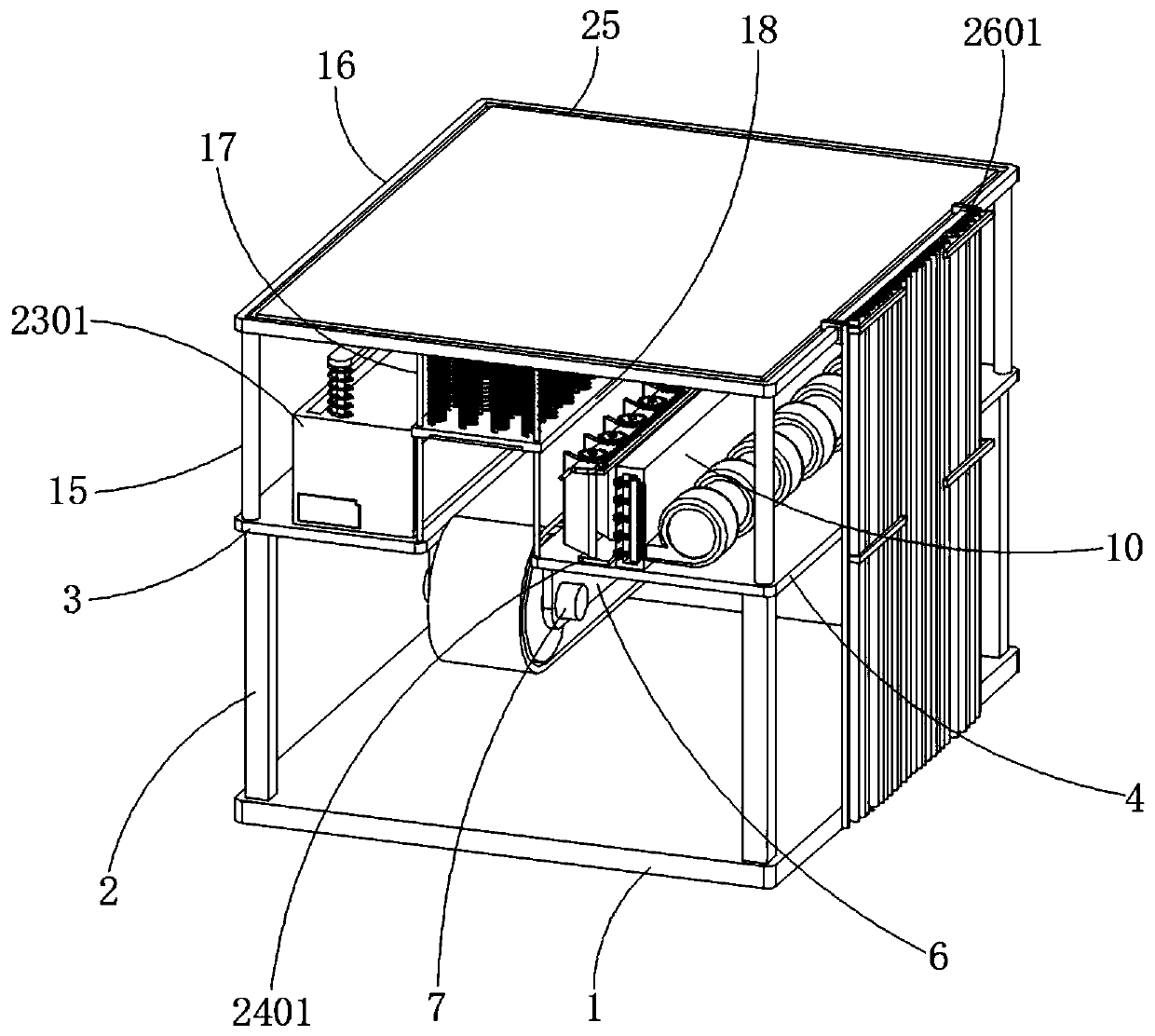

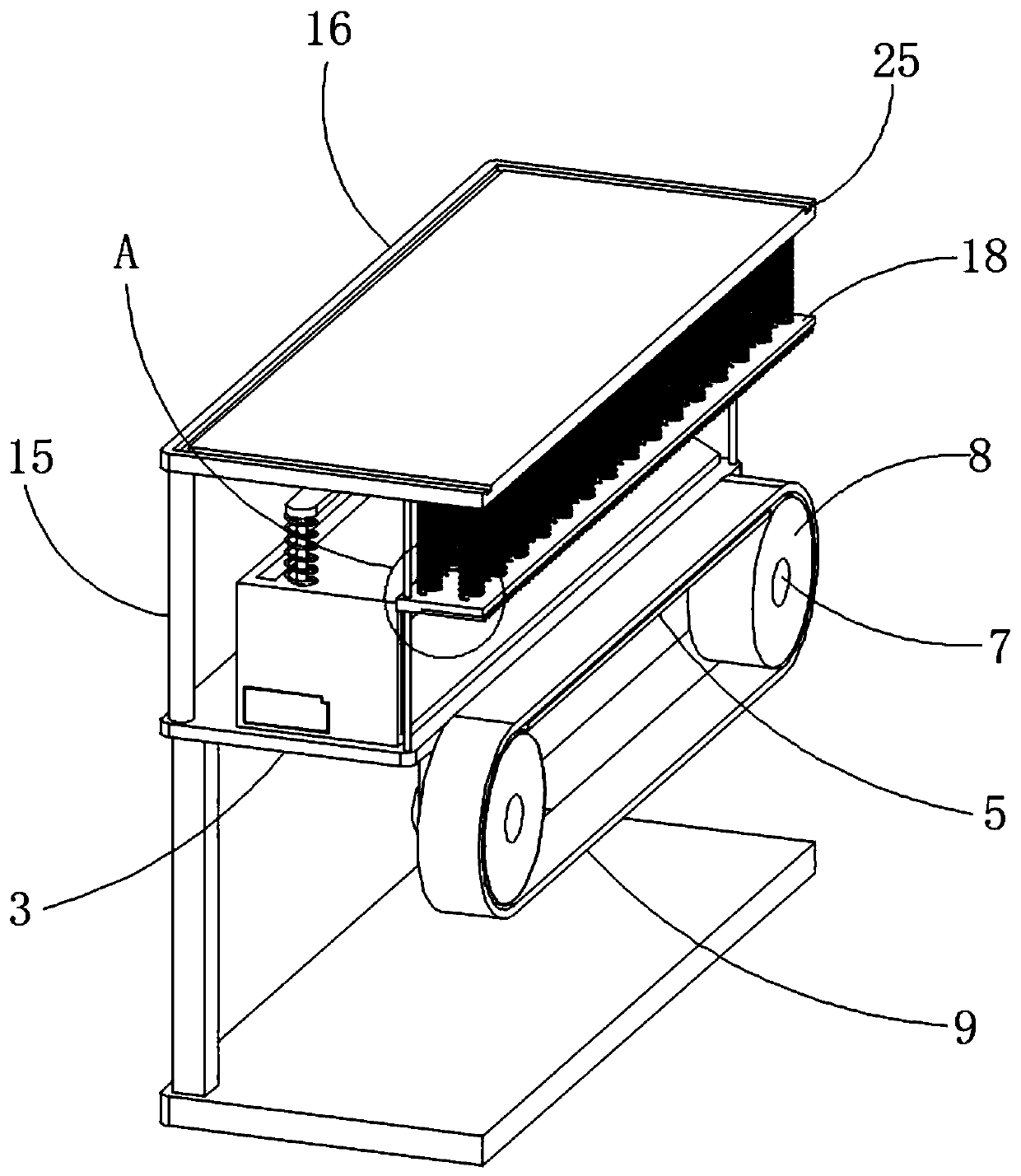

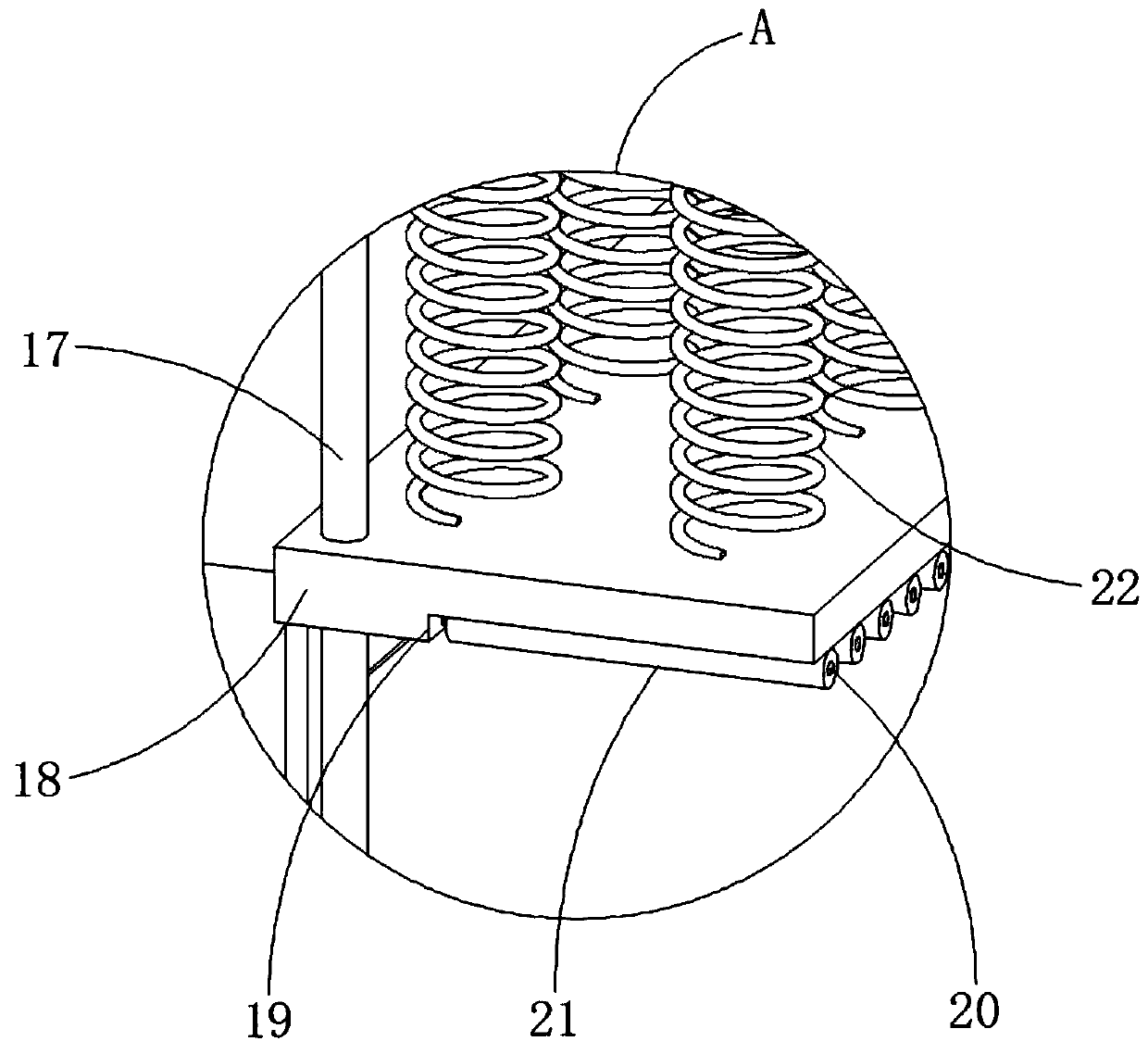

[0046] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a through-hole soot blowing device used in the processing of mechanical parts, including a support base plate 1, and a first support frame 2 is welded at each corner position of the top end of the support base plate 1. The tops of the two first support frames 2 on one side of the top of the support base plate 1 are welded with a first middle plate 3, and the tops of the two first support frames 2 at the other side of the top of the support base plate 1 are welded with a second middle plate 4, and the second A support plate 5 is connected between the middle plate 4 and the first middle plate 3, and the support plate 5 connects the second middle plate 4 and the first middle plate 3 to ensure the stability of the two, and facilitate the installation of other parts at the top and bottom of the two. , one side of the bottom end of the second middle plate 4 and one side of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com