Wave tooth composite gasket

A composite gasket and corrugated tooth technology, applied in the direction of engine sealing, flange connection, passing components, etc., can solve the problems of affecting the sealing effect, corrosion and damage of corrugated composite gaskets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the drawings.

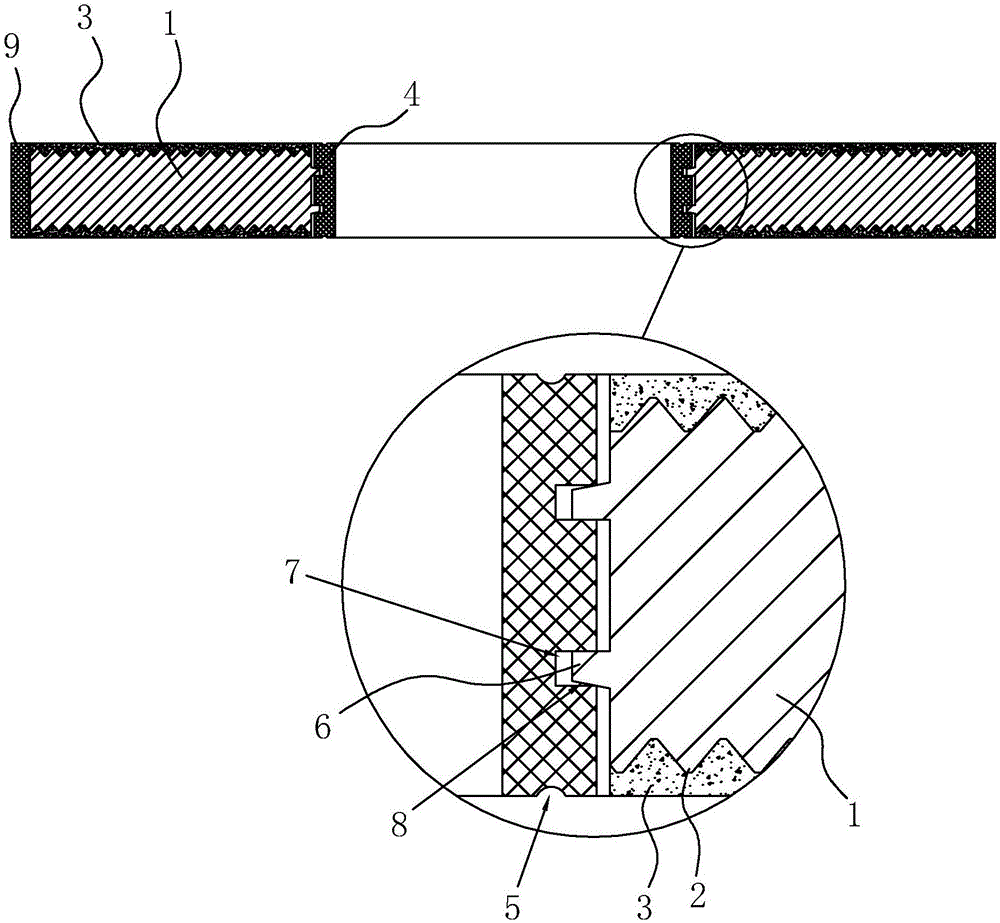

[0024] As attached figure 1 The corrugated composite gasket shown includes a ring-shaped metal frame 1. The upper and lower sides of the ring-shaped metal frame 1 are provided with corrugated teeth 2 arranged concentrically with the ring-shaped metal frame 1. The cross-sectional shape of the corrugated teeth 2 is an isosceles trapezoid. Here, the tooth tips of the corrugated teeth 2 on the upper and lower sides of the annular metal skeleton 1 are arranged in a staggered manner. The upper and lower sides of the annular metal skeleton 1 are also compounded with a flexible non-metallic layer 3, and the flexible non-metallic layer 3 is a flexible graphite layer made of expanded graphite.

[0025] A first annular rubber ring 4 made of fluororubber material is provided on the inner ring surface of the ring metal frame 1, and a second ring rubber ring 9 is sleeved on the outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com