Rolling type constant flow fluidic efflux hammer

A technology of jet impingement and constant flow rate, which is applied to the drilling driving device, drilling equipment, earth-moving drilling and other directions in the wellbore. resistance, improve the effect of impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

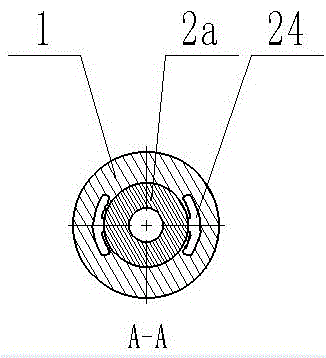

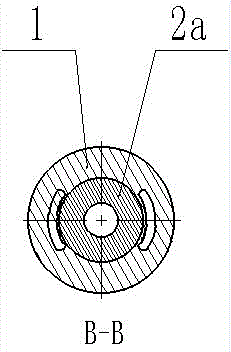

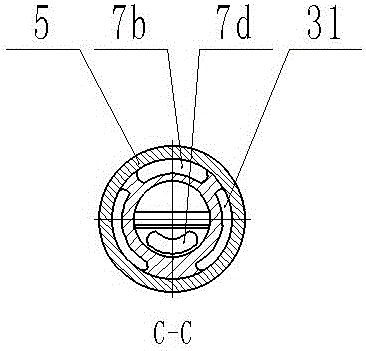

[0020] Such as Figure 1-Figure 8 As shown, a rolling type constant flow jet impactor of the present invention is characterized in that: a rolling type constant flow jet impactor is composed of an upper joint 1, a diverter valve assembly 2, a bistable jet element 6, and an inner cylinder body 7 , energy storage leaf spring 30, integral piston 8, impact hammer 18, ball assembly 19, ball assembly 21 and lower joint 23 and form. The upper end of the upper joint 1 is connected with the drill collar through threads, the lower end of the upper joint 1 is connected with the first middle joint 5 through threads, and the first retaining ring 3 and the first O-ring are arranged between the upper joint 1 and the first middle joint 5 4. The diverter valve assembly 2 is composed of a diverter valve 2a and a disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com