Noise attenuation device and fluid coupling comprised thereof

a technology of fluid couplings and noise attenuation devices, which is applied in the direction of shock absorbers, machines/engines, mechanical equipment, etc., to achieve the effect of reducing wear and erosion damage, and improving noise attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

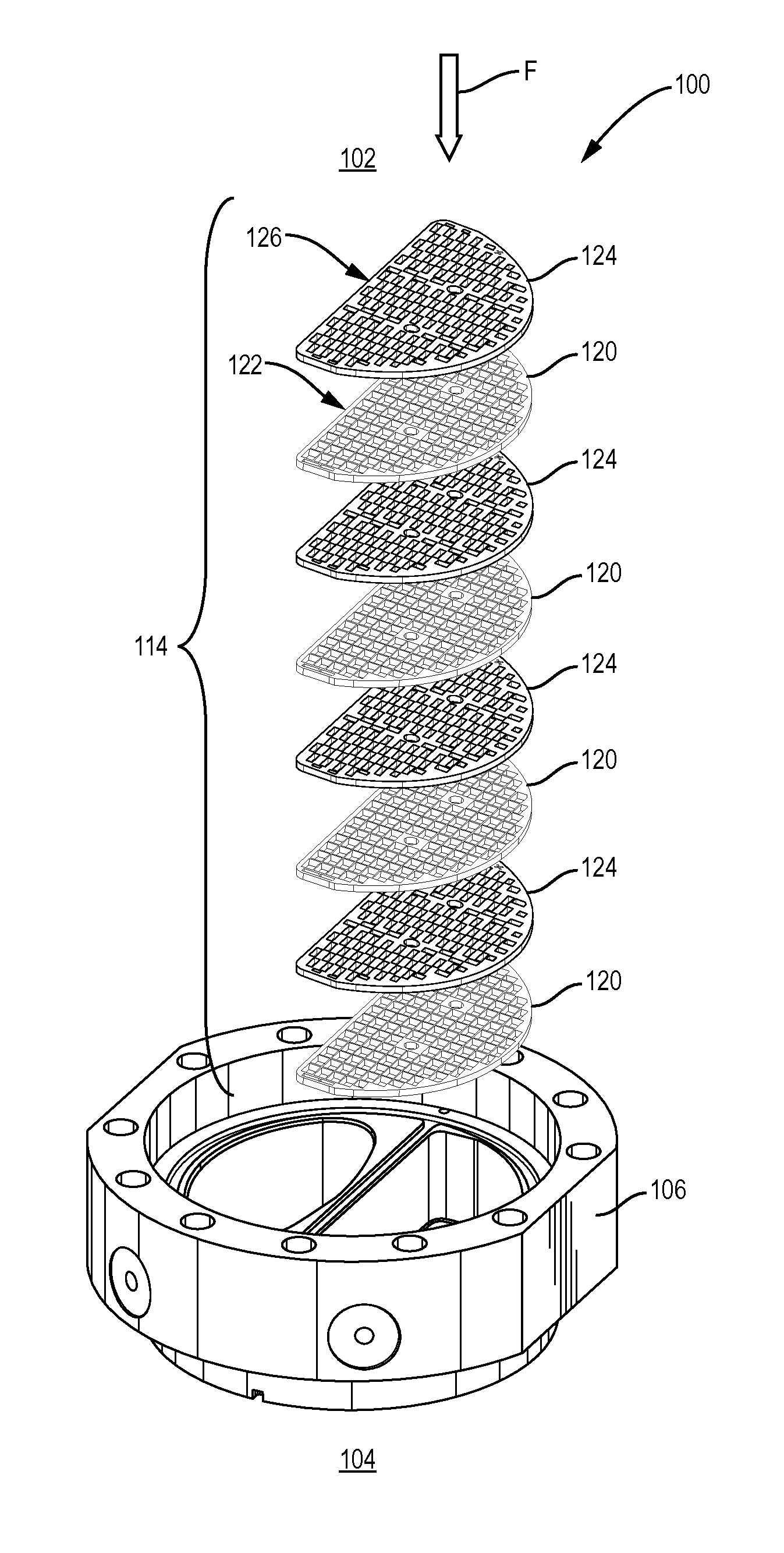

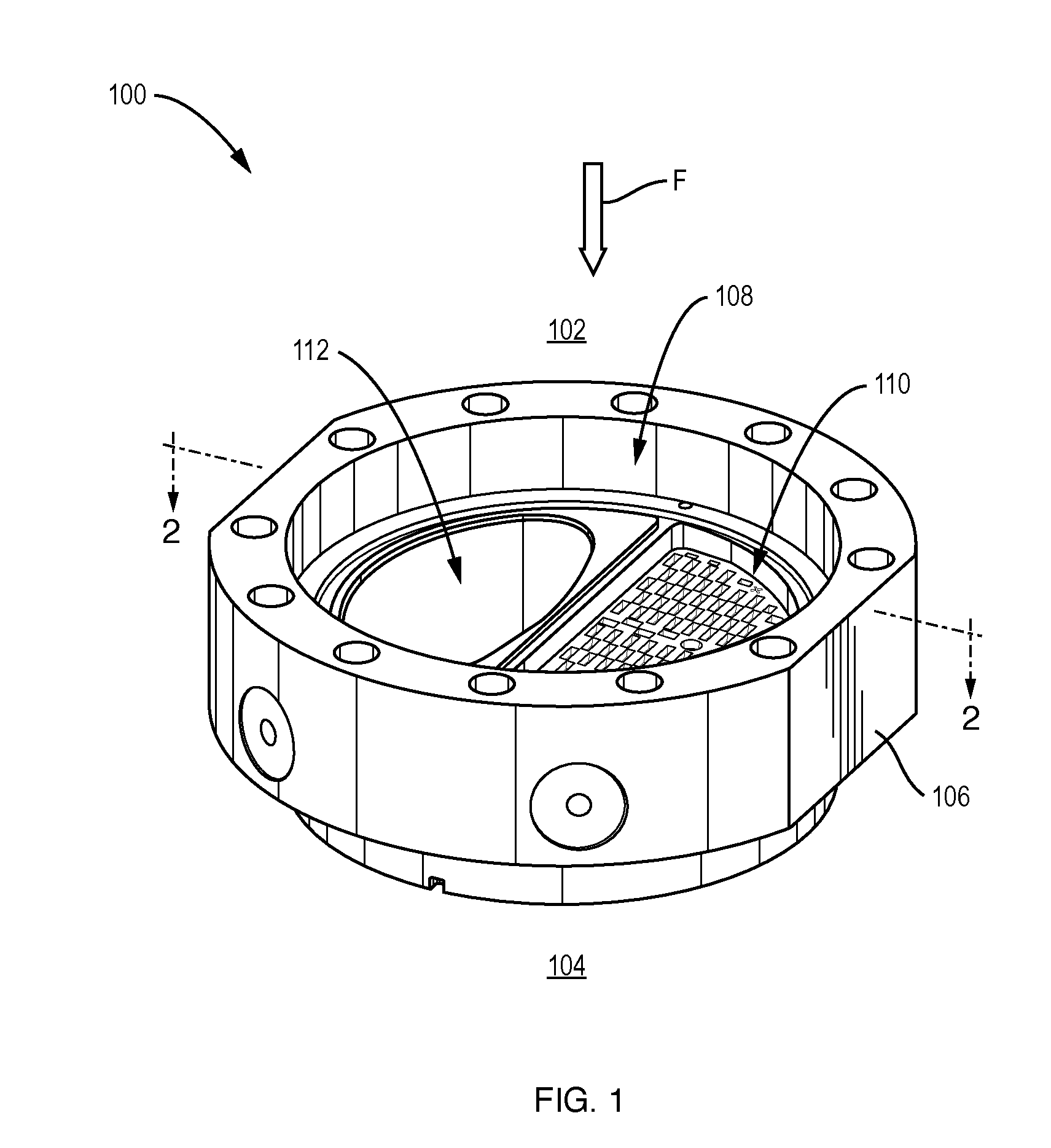

[0024]FIGS. 1, 2, 3, and 4 illustrate an exemplary embodiment of a noise attenuation device 100 (also “device 100”) that can reduce noise that occurs in fluid couplings (e.g., valves and flow regulators). In FIG. 1, the device 100 has an upstream side 102 and a downstream side 104, the orientation of which depends on the direction of flow F of a working fluid. The device 100 includes a housing 106 that forms a central opening 108 with one or more apertures (e.g., a first aperture 110 and a second aperture 112) found therein. Examples of the housing 106 can comprise carbon steel and like materials suitable for transport of fluids, e.g., natural gas. The housing 106 can fit into existing flow couplings, thereby permitting the noise attenuation device 100 much flexibility for retrofit into existing couplings and related devices.

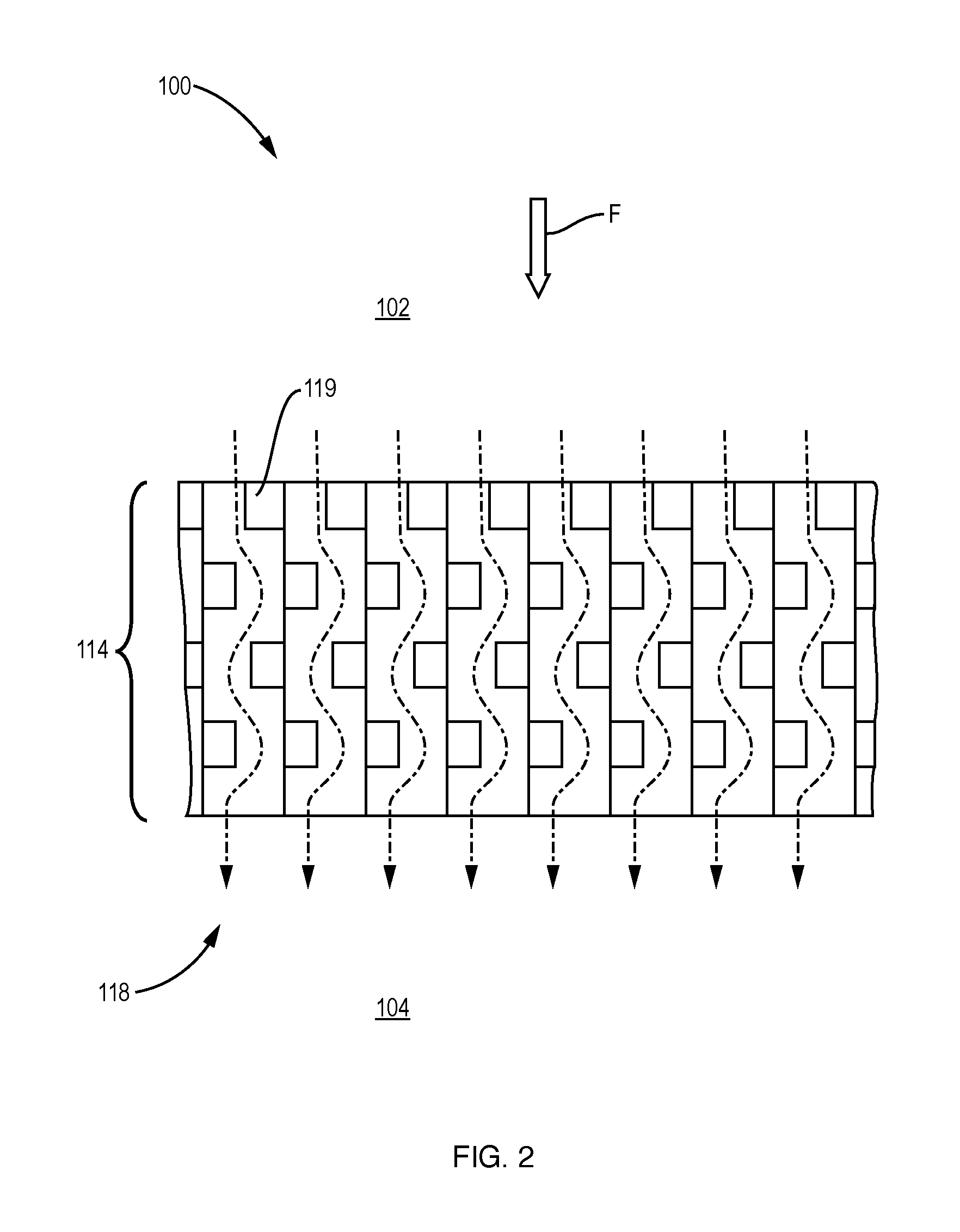

[0025]As best shown in FIG. 2, which is a cross-section of the first aperture 110 taken at line 2-2 in FIG. 1, the device 100 also includes a plate assembly 114...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com