Direct current motor for vehicle

A technology for DC motors and vehicles, applied in vehicle components, DC commutators, electromechanical devices, etc., can solve problems such as insufficient safety, increase the overall size of the motor, and inability to fail the motor, so as to improve safety and reliability, increase Noise attenuation effect, effect of eliminating short-circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

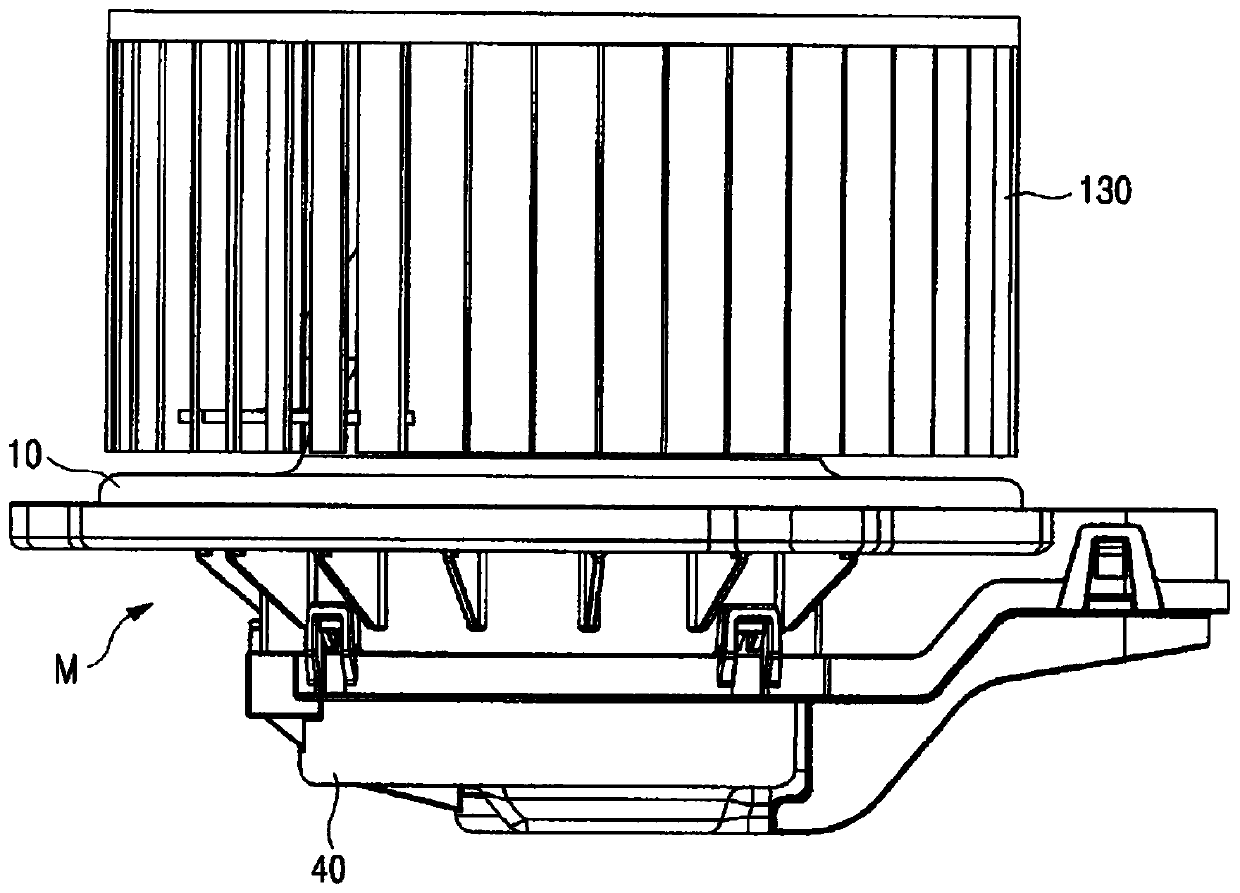

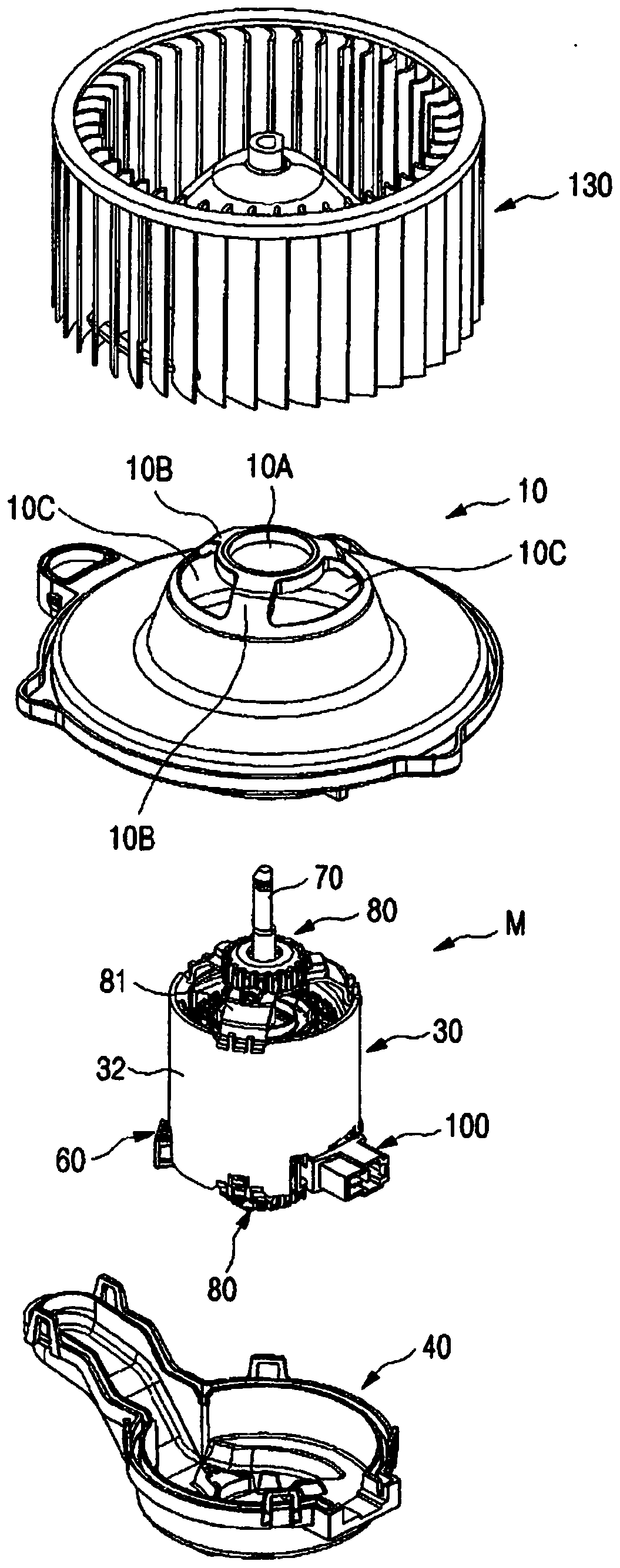

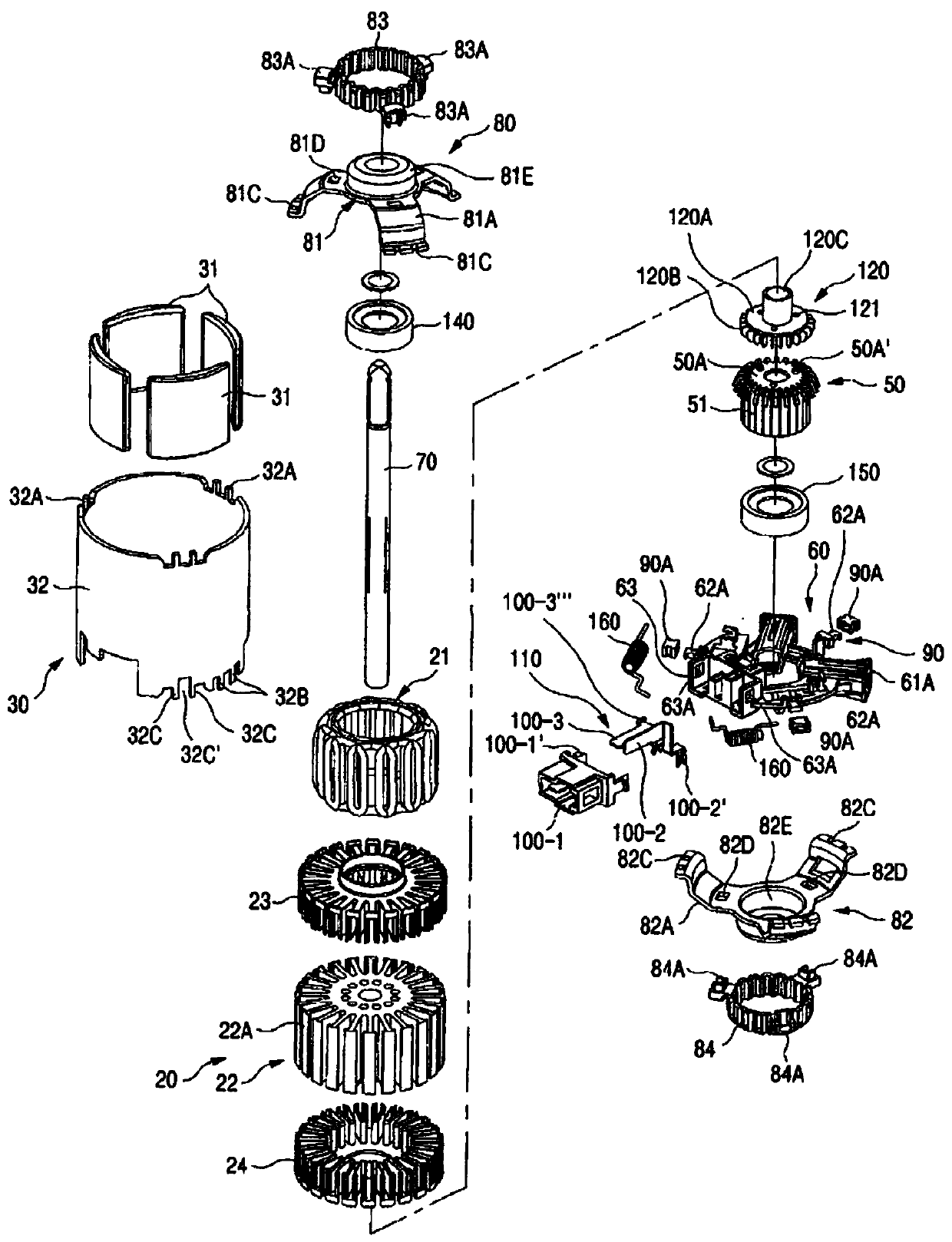

[0052] figure 1 It is a structural diagram of the motor of the present invention, figure 2 For the exploded stereogram, image 3 for with figure 2 The exploded perspective view of the DC motor drive section in Figure 4 It is a combined sectional view of the motor of the present invention.

[0053] refer to Figure 1 to Figure 4 , to illustrate the overall structure of the present invention, the motor M of the embodiment of the present invention includes a cover assembly 10 , an armature assembly 20 , a yoke assembly 30 and a lower housing 40 .

[0054] The DC motor M of the present invention has a lower case 40 combined with the cover assembly 10 and includes a yoke assembly 30 having a plurality of field poles 31 disposed inside the cover assembly 10 . The armature assembly 20 includes: an armature core 22 having a plurality of pole teeth 22A for winding a coil 21 interacting with the above-mentioned field pole 31; Combination of upper and lower parts. The commutato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com