Viscosity-reducing sand-carrying fluid and preparation method thereof

A sand-carrying liquid and viscosity-reducing technology, which is applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve the problem of unimproved flow capacity of heavy oil in the near-wellbore area, reduced flow capacity of formation crude oil, and decline in liquid production, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

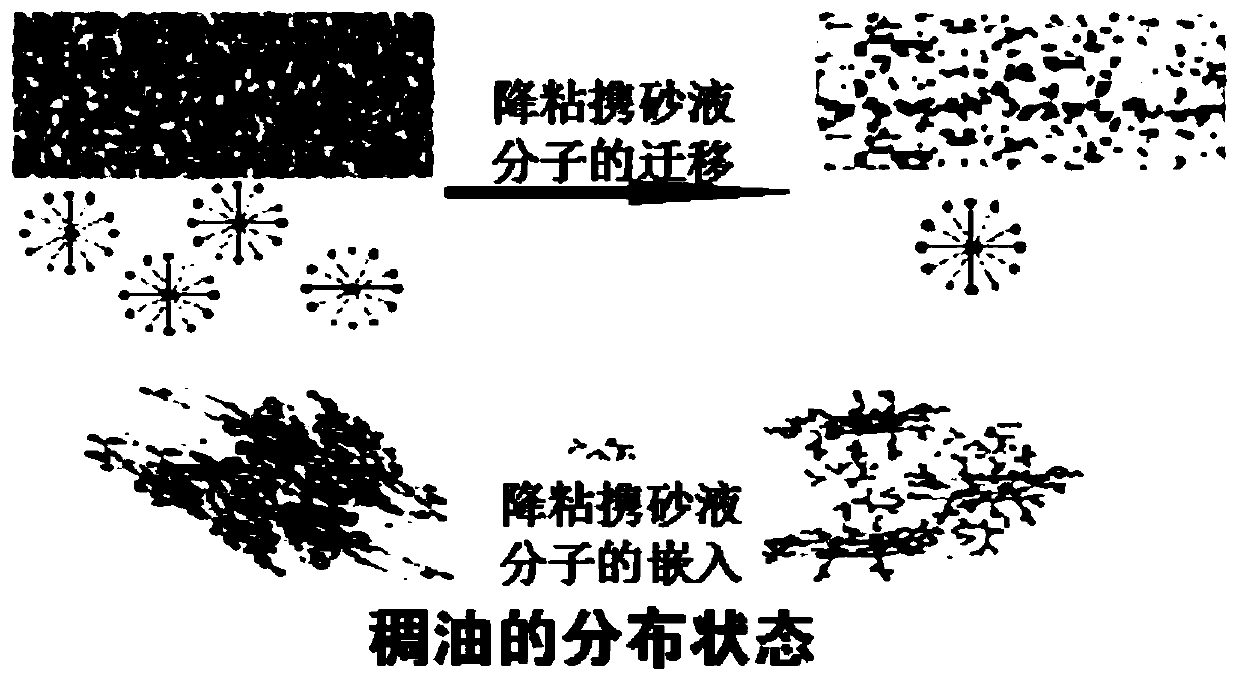

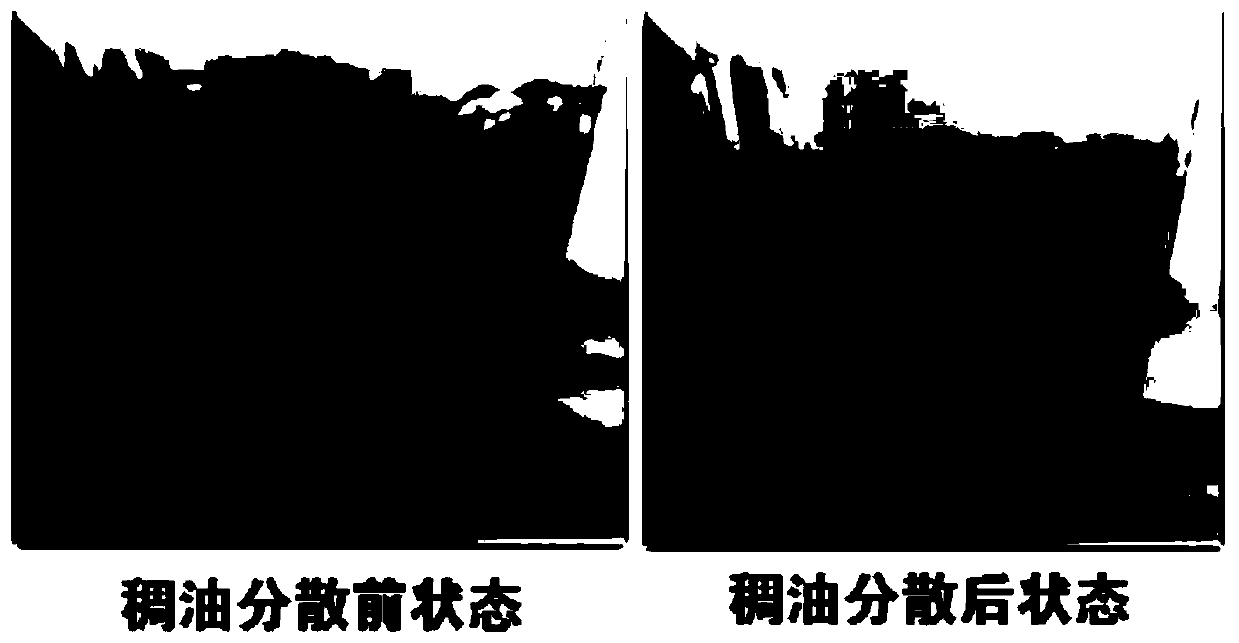

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: add 400ml tap water in the clean beaker, adjust the stirrer rotating speed to the vortex that liquid forms and can see till the top of the stirrer paddle axis, keep the stirrer to rotate at a constant speed, take by weighing 1g modified guar gum according to the formula Add water slowly, then weigh 4g anti-swelling agent hydroxyaminopolyetheramine, 0.8g drainage aid sodium perfluorononenyloxybenzene sulfonate, 10g demulsifier polyoxyethylene polyoxypropylene phosphate and 20g viscosity reducer The organosilicon sulfonate is added to the solution in sequence and stirred evenly, and after each additive is added, the next additive is added after stirring evenly, so that the viscosity-reducing and sand-controlling liquid system solution is obtained.

[0032] The performance index of the solution after preparation is as follows:

[0033] 1) Stability performance: stability at room temperature

[0034] Store a viscosity-reducing sand-carrying fluid in a sealed ...

Embodiment 3

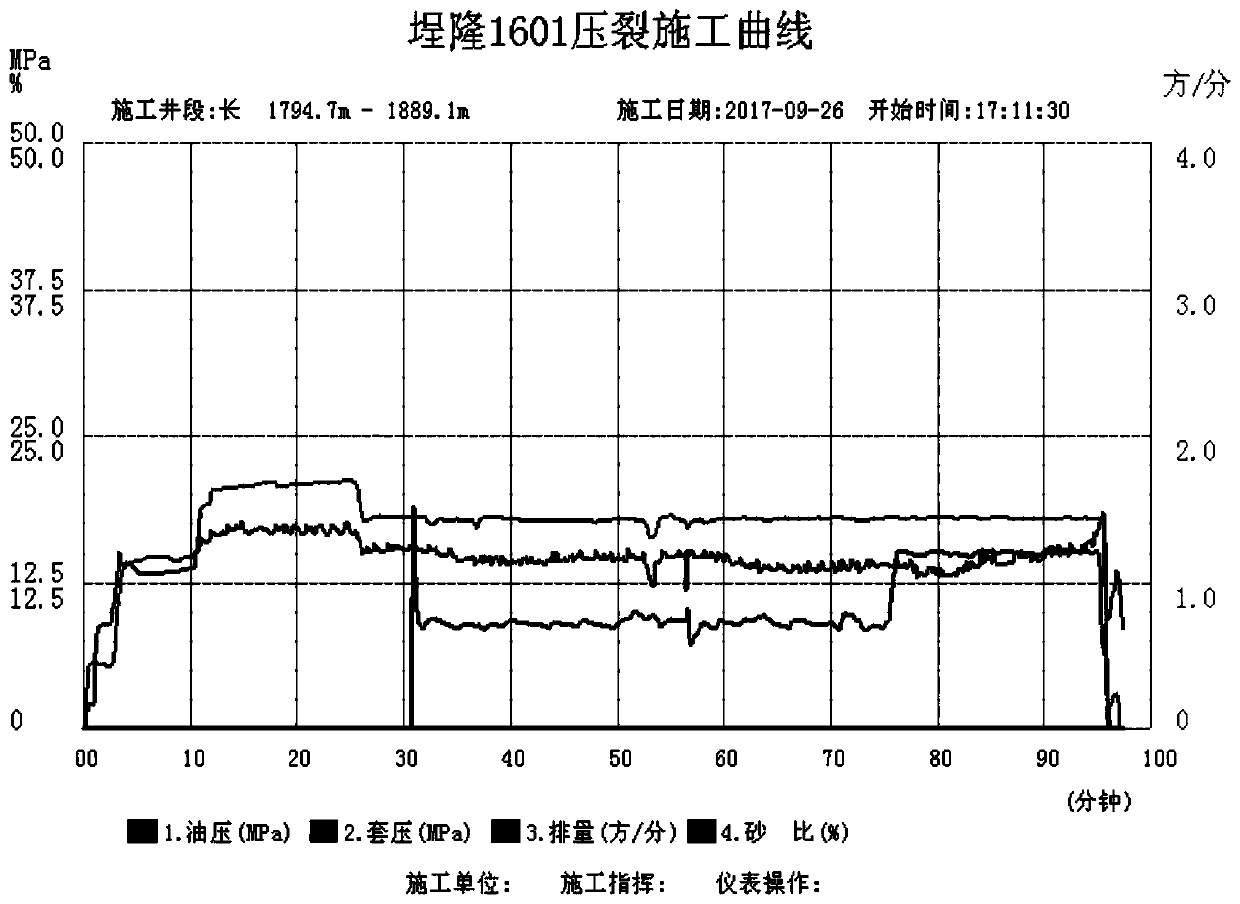

[0070] Example 3: Pumping well Chenglong 1601 well, sand control layer Ng14#, 15-1#, sand control well section: 1252.2-1256.3m, 1261.8-1265.8m, this well is located in the heavy oil well area, sand plugging is serious, and extrusion is preferred The sand control technology of gravel packing is used for sand control, and the viscosity-reducing sand-carrying fluid is used to carry the gravel filling to the depth of the formation, near the wellbore and the annulus, so as to form a multi-level sand retaining barrier and restore the normal production of the oil well. After the sand control construction, the daily oil production is 2.68 tons, and the daily liquid production is 7.62m 3 , the water content is 64.86%, and the effect of sand control and production increase is obvious.

[0071] The composition of a viscosity-reducing sand-carrying fluid formula of this well is as follows:

[0072] 0.25% guar gum + 1.0% anti-swelling agent + 0.2% drainage aid + 2.5% demulsifier + 4% visc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com