Process for backwashing permeable downhole filter by high pressure fluid column in oil conduit

An internal high pressure, sand filter tube technology, which is applied in the fields of production fluids, wellbore/well components, earthwork drilling, etc., can solve the problems of low oil pumping efficiency and short service life of oil well pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

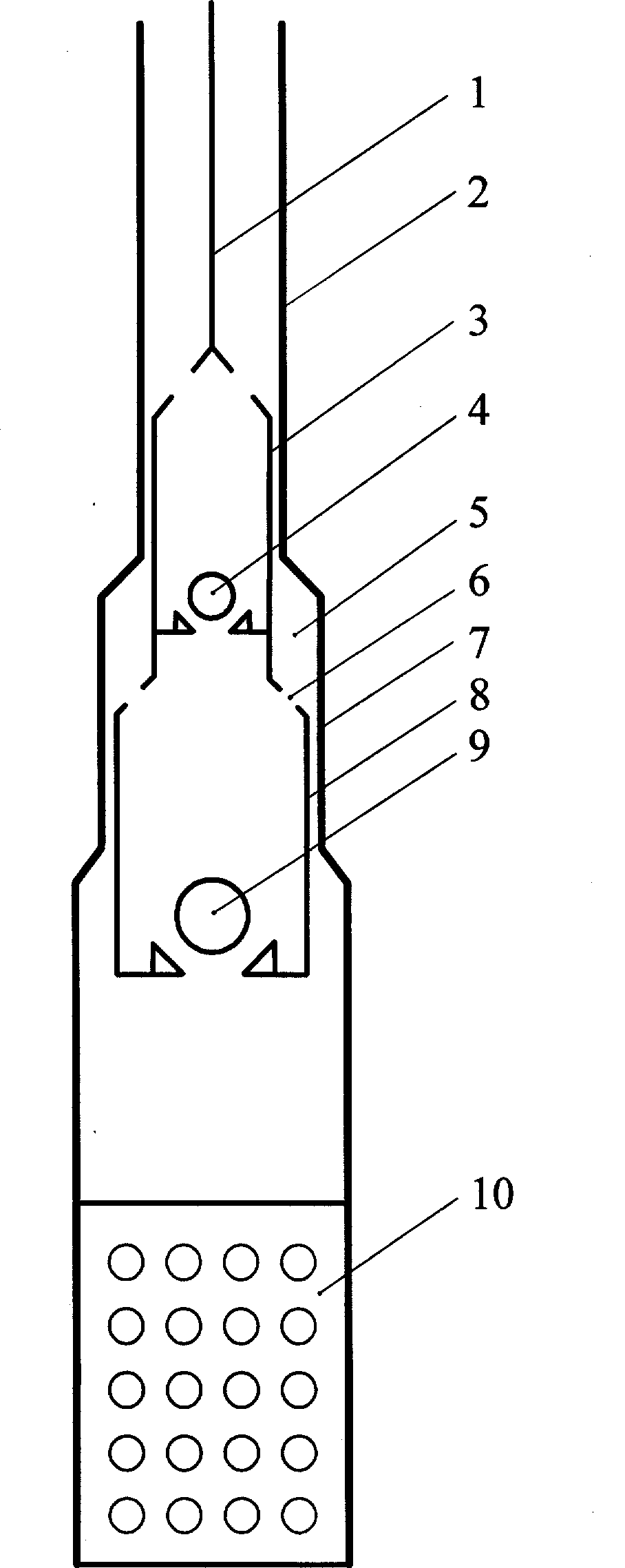

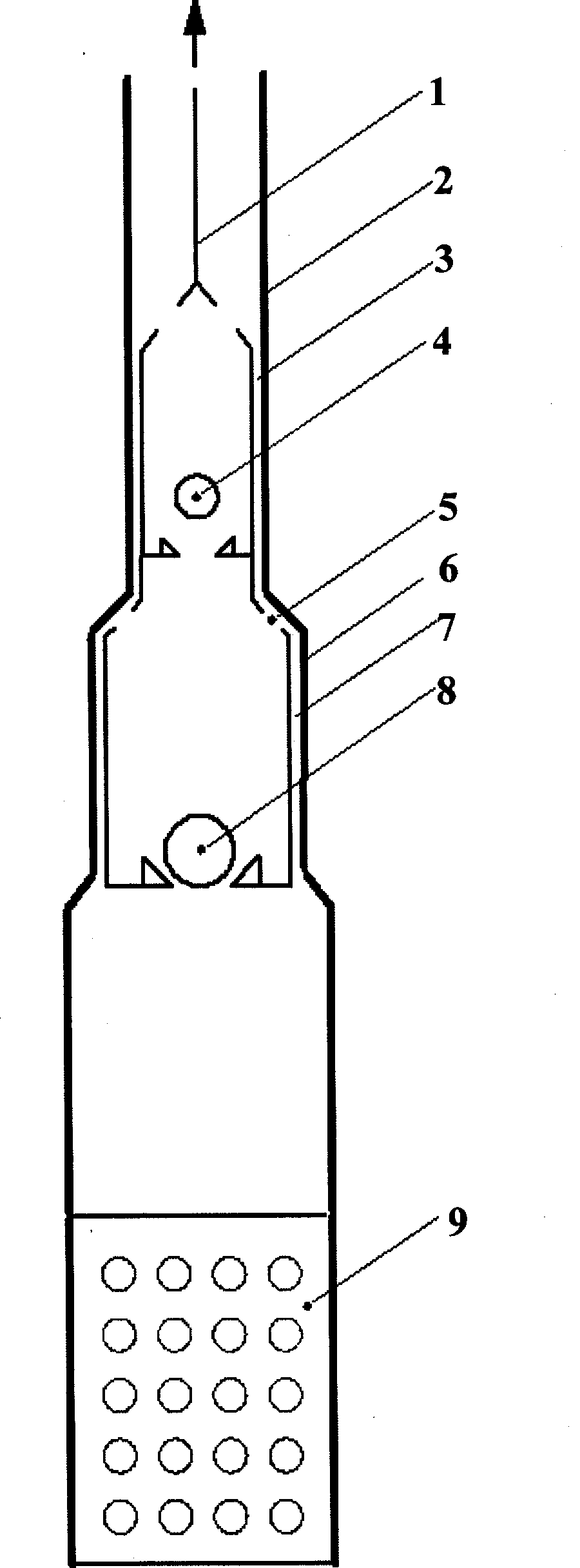

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] 1. According to the process of backwashing the sand filter pipe with high-pressure liquid column in the oil pipe, and according to the attached drawings, the plunger structure of the oil well pump is reasonably designed and calculated;

[0029] 2. Select the most suitable pumping unit according to the process of backwashing the sand filter pipe with the high-pressure liquid column in the oil pipe and the parameters of the pump;

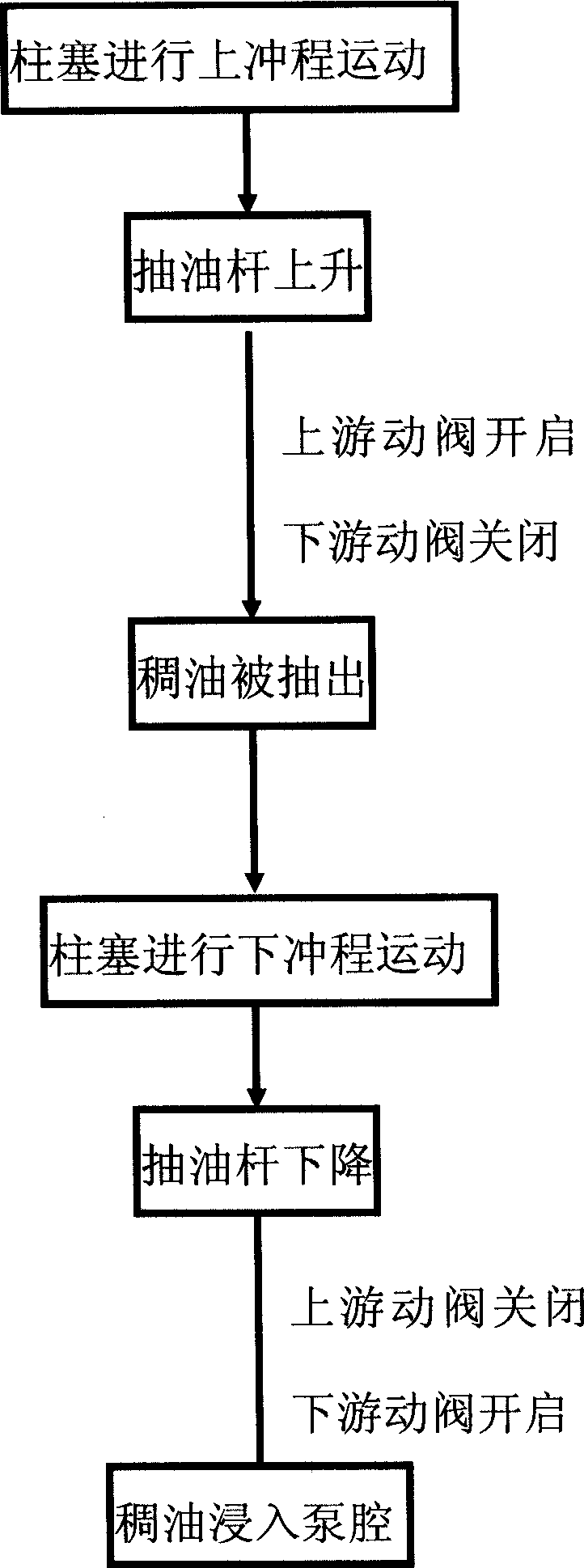

[0030] 3. According to the process of backwashing the sand filter pipe with the high-pressure liquid column in the oil pipe, when the oil pump is in the normal production process, it follows the designed theoretical displacement to produce oil; When the plunger is lowered by a certain distance, the high-pressure liquid column in the tubing is released, and flows back into the wellbore through the pump chamber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com