Casing sidetracked well completion method using expansion screen tube

A screen tube completion and sidetracking technology, which is applied in wellbore/well components, earthwork drilling, production fluid, etc., can solve problems such as easy sand plugging and small inner diameter of sand control screen, and achieve low operating costs and reduced production cost, effectiveness in reducing sand impact and erosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

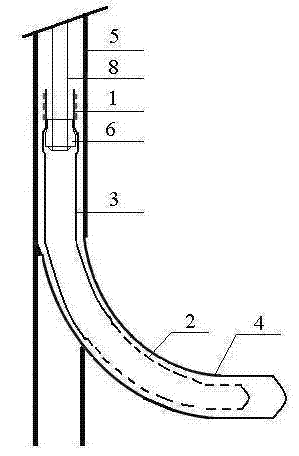

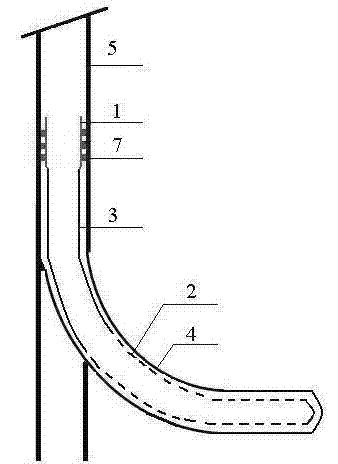

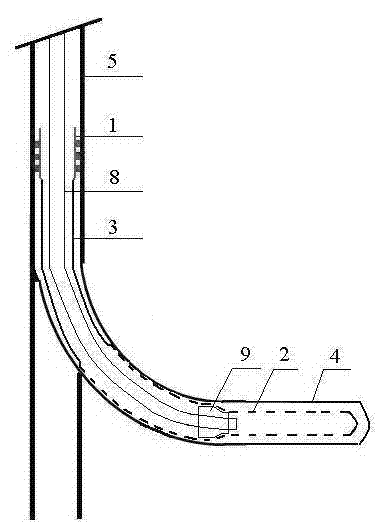

[0019] The method of the present invention will be further described in conjunction with the accompanying drawings.

[0020] like Figure 1~Figure 5 As shown, the completion liner of the sidetracking well is mainly the expansion screen 2, which is suspended and sealed by the expansion hanger 1, and a large-diameter casing 3 can be appropriately added between the expansion hanger 1 and the expansion screen 2 according to requirements. The expansion hanger 1 is located at the top of the pipe string, and its outer surface is processed to provide a suspension sealing rubber ring 7, and the bottom is processed with a bell-shaped starting device for prefabricating the expansion cone 6; the expansion screen 2 mainly includes the expansion base pipe 10. The filter screen 11 and the protective cover 12 have a three-layer structure. The expansion base pipe 10 is evenly processed with slots, and the filter screens 11 partially overlap each other and are sandwiched between the expansion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com