Low-density foam resin sand preventing agent suitable for sand production horizontal well of unconsolidated sandstone reservoir and preparation method of low-density foam resin sand preventing agent

A sandstone oil reservoir and foam resin technology, applied in chemical instruments and methods, earthwork drilling and production, wellbore/well parts, etc., can solve the problems of high curing temperature, high density, low consolidation strength, etc., and achieve simple preparation process , improve the effect and benefit, reduce the effect of formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

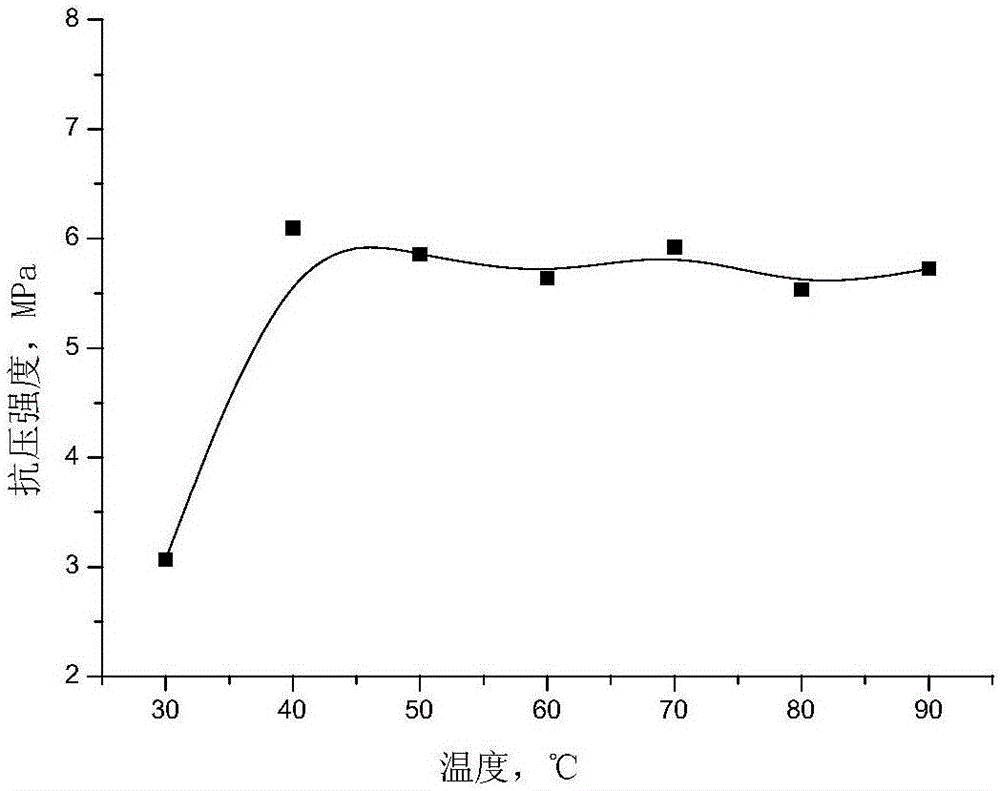

[0011] A low-density foam resin sand control agent suitable for sand production horizontal wells in unconsolidated sandstone reservoirs. The sand control agent has an apparent density of 0.558-0.634g / cm at normal temperature (25°C) 3 , its raw material components and weight percentages are as follows:

[0012] 97.1% to 98.85% of cementing agent, 0.3% to 0.8% of foaming agent, 0.7% to 1.3% of foam stabilizer, 0.05% to 0.5% of curing agent, and 0.1% to 0.3% of coupling agent.

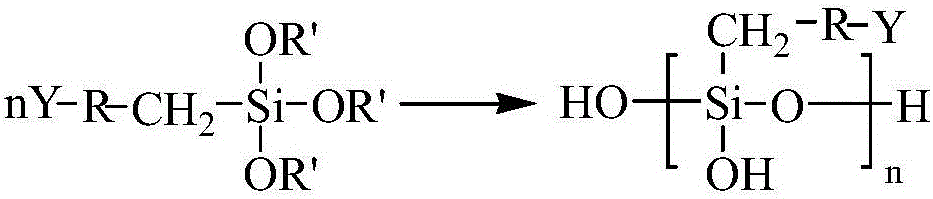

[0013] Preferably in the present invention, the binder is a melamine-formaldehyde resin solution obtained by mixing melamine-formaldehyde resin powder and water at a mass ratio of (1-3):5.

[0014] Further preferably, the binder is a melamine-formaldehyde resin solution prepared by mixing melamine-formaldehyde resin powder and water at a mass ratio of 2:5.

[0015] Preferably in the present invention, the foaming agent is an anionic surfactant.

[0016] Further preferably, the foaming agent is sodium do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com