Horizontal well horizontal section relative sand outlet deficit profile prediction and sand prevention section grading method

A grading method and horizontal section technology, applied in the field of oil and gas exploration, can solve the problems of affecting the output of oil and gas wells, unfavorable economic benefits, and different degrees of sand production, and achieve the effects of ensuring long-term stable production, improving economic benefits, and improving sand control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] A method for predicting the relative sand production deficit profile of the horizontal section of a horizontal well and for sand control segmentation classification, comprising:

[0078] S1: According to the horizontal well logging data (density logging, compressional wave logging, shear wave logging) to calculate the distribution of reservoir rock mechanics parameters along the horizontal section of the horizontal well, the reservoir rock mechanics parameters include dynamic Poisson's ratio, static Poisson's ratio , dynamic elastic modulus, uniaxial compressive strength, cohesion and internal friction angle;

[0079] The calculation formula of dynamic Poisson's ratio is shown in formula (I):

[0080]

[0081] In formula (Ⅰ), μ d — dynamic Poisson’s ratio of rock, dimensionless; Δt h — S-wave time difference, μs / m; Δt v — longitudinal wave time difference, μs / m;

[0082] The calculation formula of static Poisson's ratio is shown in formula (II):

[0083] μ=A·μ ...

Embodiment 2

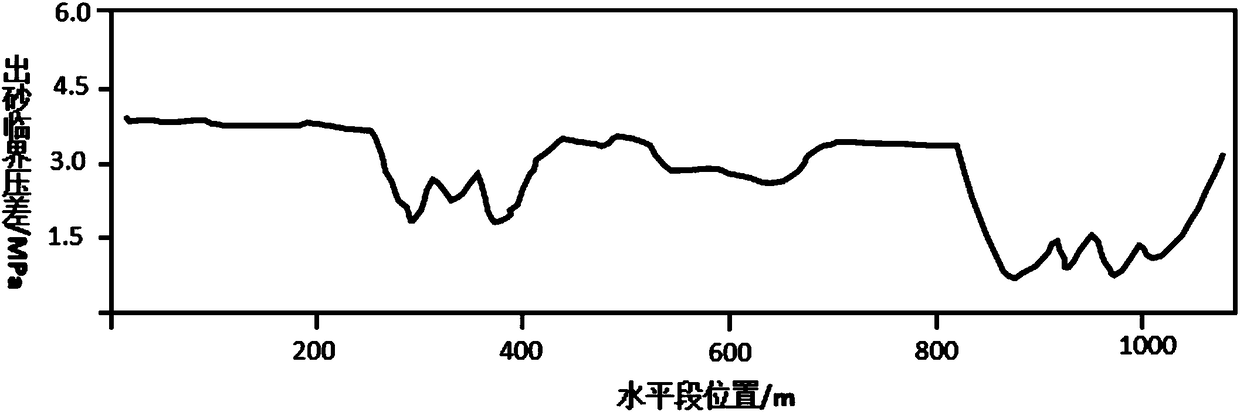

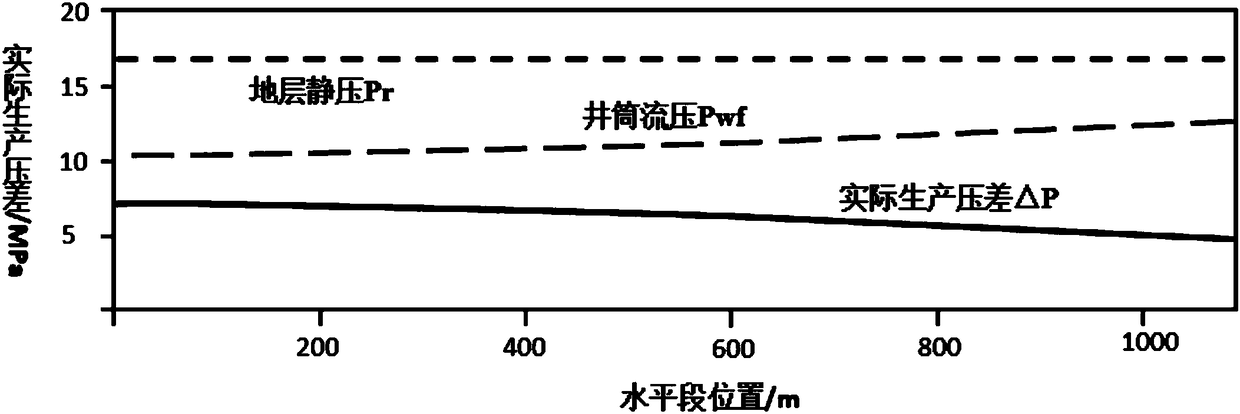

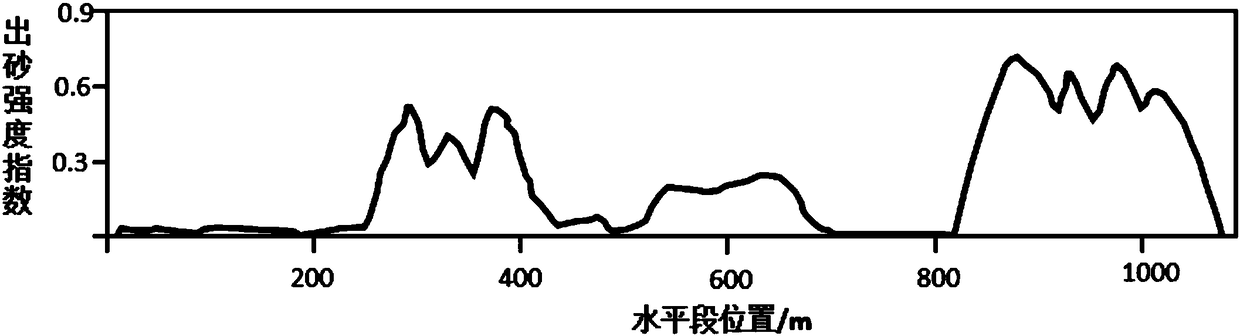

[0121] The relative sand production deficiency profile prediction and sand control segmentation method of a horizontal well horizontal section described in Example 1 is used. This method is applied to the horizontal section of a horizontal well in a certain oil reservoir in Dagang Oilfield. The horizontal section of the horizontal well is 580m long and has a water cut of 85. %, liquid production is about 180t / d. Utilize the method of Example 1 to predict and obtain the critical sand production pressure difference, production pressure difference, and sand production net pressure difference distribution schematic diagram of the horizontal section as shown in Image 6 shown. The schematic diagram of multi-segment and multi-level division results of graded sand control in horizontal section is as follows Figure 7 shown.

[0122] According to the evaluation results, the sand production and sand control of the entire horizontal section is divided into 8 sections, such as Figure...

Embodiment 3

[0124] A method for predicting the relative sand production deficit profile of the horizontal section of a horizontal well and segmented sand control classification method described in Example 1 is used. This method is applied to the horizontal section of a horizontal well in a heavy oil reservoir in Shengli Oilfield. The horizontal section of the horizontal well passes through three layers, and the horizontal section lengths are 25m, 35m and 400m respectively.

[0125] Utilize the method of embodiment 1 to predict and obtain the sand production profile of the horizontal section and the subsection sand control evaluation results as follows Figure 8 shown. According to the evaluation results, the first layer section A is a moderate sand production section, which requires secondary sand control; the second layer B section is a slight sand production section, which requires primary sand control; the third layer C, E, and G are medium The well section with sand production requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com