Method for processing sieve tube composite seam

A processing method and technology of screen tubes, which are applied in the field of mechanical processing, can solve the problems of high scrap rate and no composite joints of screen tubes, etc., and achieve the effect of improving strength and sand control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

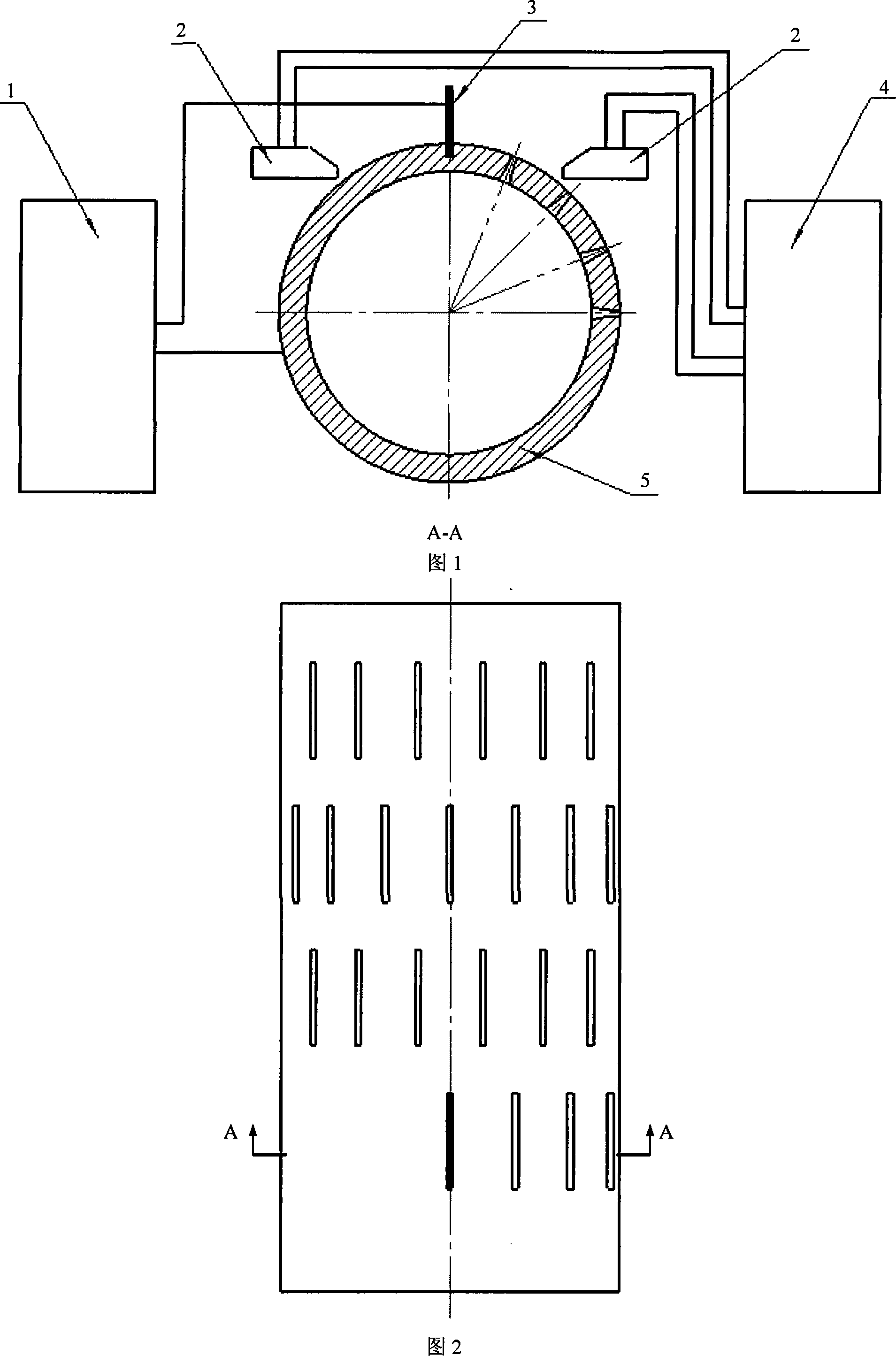

[0013] See Figure 1. In the schematic diagram of the processing principle of the method for processing the composite seam of the screen pipe of the present invention, 1 is a controllable plasma power supply, which is mainly used to provide controllable plasma processing electric energy, which can be automatically adjusted according to the processing requirements and the change of the processing depth. For compound seams with narrow inner width, as the processing depth increases, the electric energy output by the controllable plasma power supply increases according to the preset law, so that the seam width can be expanded as required; 2 is the electromagnetic oscillation head, one is placed on each side of the seam, It is mainly used to generate an alternating electromagnetic field, so that the plasma is regularly deflected to both sides of the slit, and the width of the processed slit is enlarged as required; 3 is a sheet tool electrode, whose material is copper, and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com