Sand prevention agent for achieving auto-aggregation of sand grains

A technology of sand control agent and sand particles, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of small action range and poor consolidation effect, and achieve the effect of improving sand consolidation strength and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

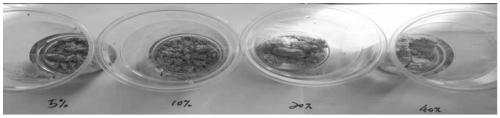

Image

Examples

Embodiment 1

[0024] The sand control agent for realizing self-aggregation of sand particles includes three parts: self-aggregation liquid, self-aggregation aid and sand-fixing agent; wherein the self-aggregation liquid is an aqueous solution of sodium alginate with a mass concentration of 0.1%; the self-aggregation aid is copper chloride Aqueous solution with a mass concentration of 0.05%; the sand-fixing agent is epoxy resin and its curing agent system.

[0025] The mass ratio of the self-aggregation liquid, the self-aggregation aid and the sand-fixing agent is 1:2:0.5.

[0026] It is taken from the polycondensation liquid to wet the sand particles, and then the sand particles soaked in the blend are introduced into the self-agglomeration aid, and the self-agglomeration sand clusters can be formed instantly, and the sand consolidation agent is introduced into the sand clusters to achieve encapsulation on the self-coalescence sand clusters. After curing at a certain temperature, a sand mas...

Embodiment 2

[0028] The sand control agent for realizing self-aggregation of sand particles includes three parts: self-aggregation liquid, self-aggregation aid and sand-fixing agent; wherein the self-aggregation liquid is an aqueous sodium metasilicate solution with a mass concentration of 5%; the self-aggregation aid is chlorinated The zinc aqueous solution has a mass concentration of 10%; the sand-fixing agent is furan resin and its curing agent system.

[0029] The mass ratio of the self-aggregation liquid, the self-aggregation aid and the sand-fixing agent is 1:5:0.2.

[0030] The above three materials, through the pumping procedure of the actual construction on site, first use 0.5 ~ 0.8m 3 / min displacement into the self-polymerizing liquid, and then 0.8 ~ 1.0m 3 / min displacement into the self-aggregation aid, and finally 0.3 ~ 0.5m 3 The sand-consolidating agent is injected at a displacement of 1 / min, so that a better self-aggregation effect of sand clusters can be formed, and the...

Embodiment 3

[0032] The sand control agent for realizing self-aggregation of sand particles comprises three parts: self-aggregation liquid, self-aggregation aid and sand-fixing agent; wherein the self-aggregation liquid is an aqueous solution of carrageenan with a mass concentration of 3%; the self-aggregation aid is an aqueous solution of cobalt sulfate, The mass concentration is 1.2%; the sand-fixing agent is phenolic resin and its curing agent system.

[0033] The mass ratio of the self-aggregation liquid, the self-aggregation aid and the sand-fixing agent is 1:5:0.3.

[0034] The sand control agent described in this example is applied to a vertical well in a tight sandstone gas reservoir, where the formation temperature is 120°C and the sunrise sand is 1.67m 3 / d, 2012.7.30-2012.8.3 metal wool sand filter pipe for sand control, the pump is mixed with water and put into production; 2013.10.15-11.2 high pressure filling 3 ); 2014.6.28-2014.7.20 plugging, layered ground filling + screen ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com