Horizontal well tube exterior subsection gravel filling sand prevention process and pipe column

A technology of gravel packing and process pipe strings, which is applied in the direction of wellbore/well components, production fluid, earthwork drilling and production, etc. It can solve the problems that the well section cannot be filled with gravel, poor sand control effect, sand control failure, etc., and achieves good sand control effect , fast speed and high success rate of sand control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

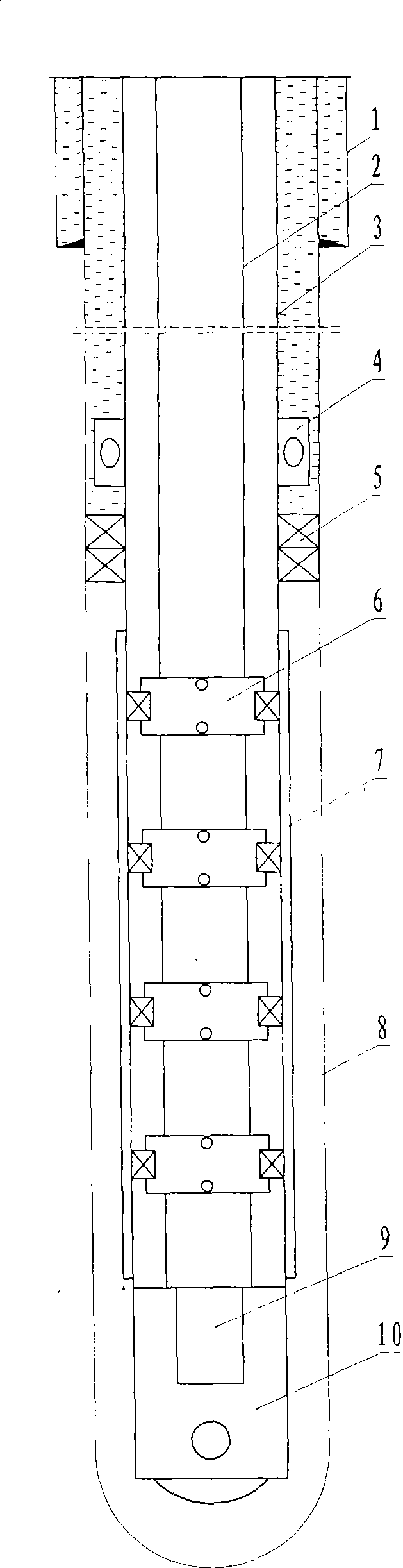

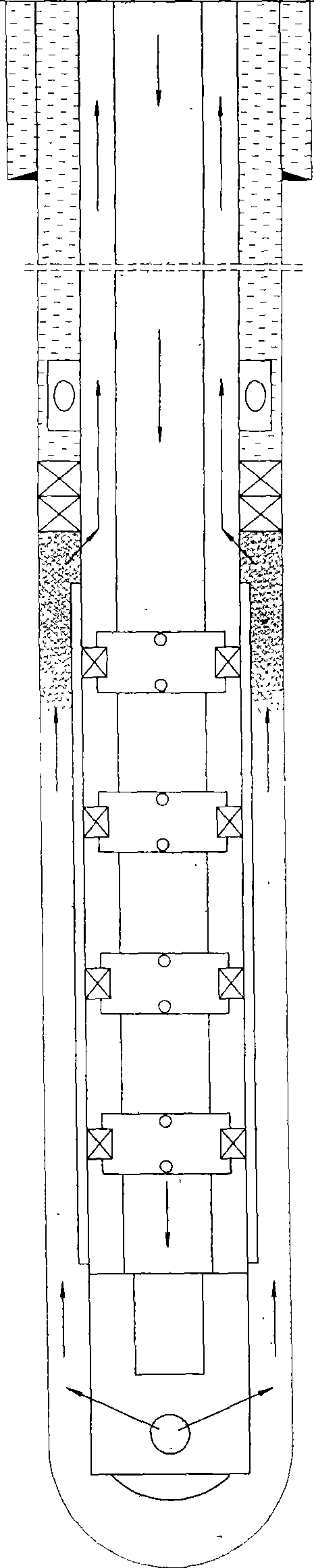

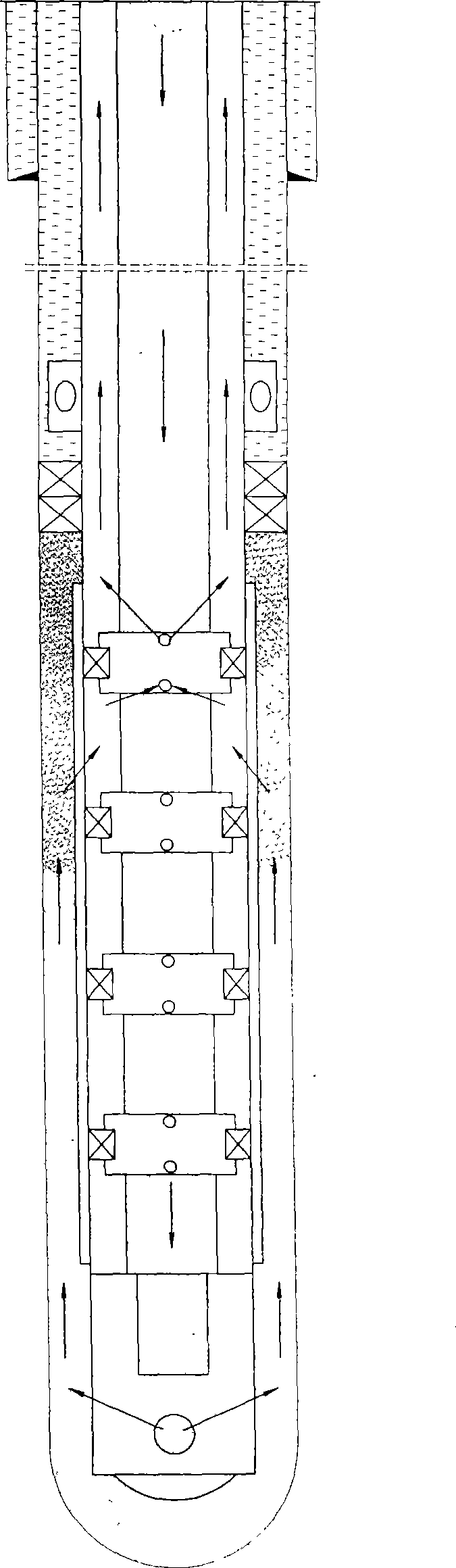

[0020] A segmented gravel packing sand control process outside a horizontal well pipe, comprising an isolated well section and segmented gravel packing, characterized in that the isolated well section is made of a segmented packer, and the sand control screen and the tubing are separated The annulus between the wells are separated into a plurality of well sections that are not connected to each other. The segmented gravel packing is performed by the segmented gravel packing sand control string, and is carried out in the following process steps: (A) the gravel is passed from the tubing through the segmented The packing packer, packing assembly and packing server are deposited outside the sand control screen at the front end of the primary packing packer. When the packing gravel deposit extends below the primary packing packer, it will automatically open under the action of pressure difference The filling channel of the next well section; (B) continuous (A) step, gravel is deposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com