Multi-section-plug high-saturation filling water and sand controlling method for silty fine sand reservoir

A silty sand, multi-slug technology, used in earth-moving drilling, production fluids, wellbore/well components, etc., to achieve high permeability, meet the requirements of sand control technology, and increase production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

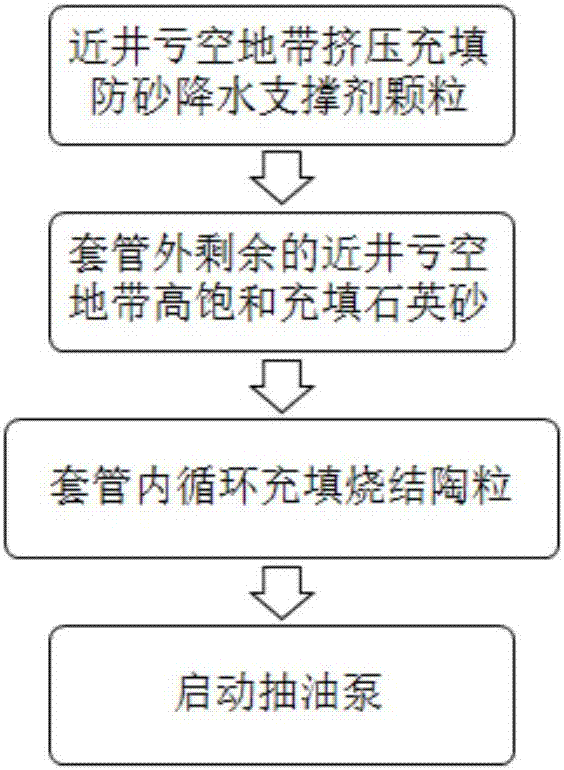

[0040] A multi-slug highly saturated filling method for controlling water and sand in silty sand reservoirs, characterized in that the method comprises:

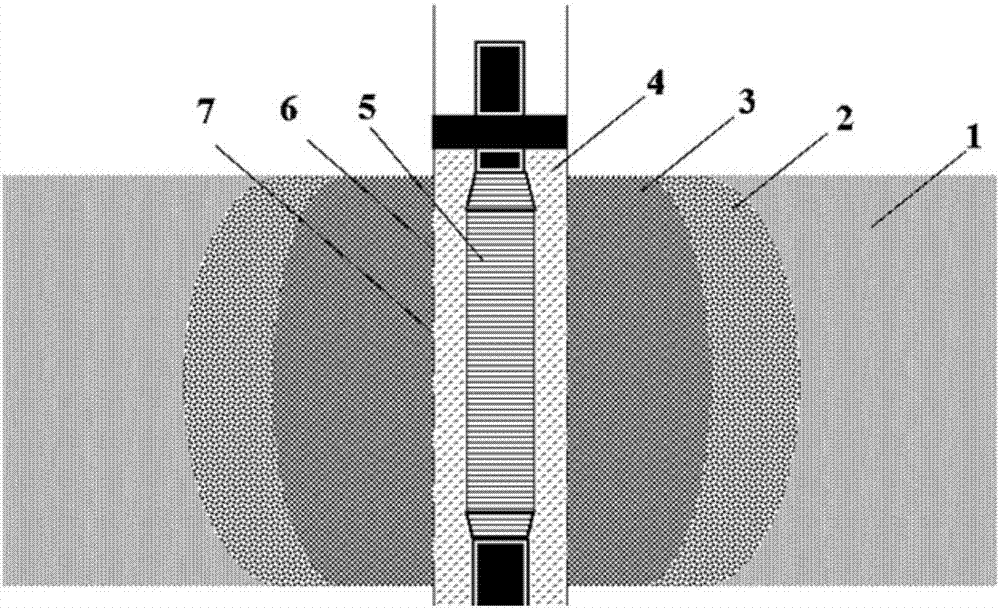

[0041] A multi-stage sand retaining barrier is set between the mechanical sand control screen 5 and the fine sand reservoir 1 .

Embodiment 2

[0043] As described in Example 1, a multi-slug high-saturation filling method for water control and sand prevention in silty sand reservoirs, the difference is that the multi-stage sand retaining barriers include: radially outwardly arranged along the mechanical sand control screen 5 sequentially :

[0044] The fourth-level sand retaining barrier, the third-level sand retaining barrier 4, the second-level sand retaining barrier 3 and the first-level sand retaining barrier 2; the third-level sand retaining barrier 4, the second-level sand retaining barrier 3 and the first-level sand retaining barrier The primary sand retaining barrier 2 contains particles of corresponding particle size.

Embodiment 3

[0046] As described in Example 1, the multi-slug high saturation filling method for controlling water and sand in silty sand reservoirs differs in that the nominal accuracy of the mechanical sand control screen 5 is 1.25 times the median particle size of the formation sand, so The mechanical sand control screen 5 forms the fourth level sand retaining barrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com